Groove butt welding structure and welding method thereof

A welding method and welding structure technology, which is applied to welding equipment, arc welding equipment, and the edge of workpieces, can solve problems such as incomplete cleaning, welding defects, and time-consuming problems, so as to reduce non-destructive inspection and improve production efficiency. The effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

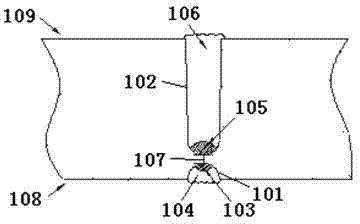

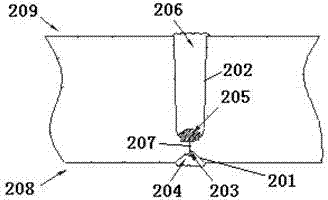

[0041] Such as figure 1 As shown, it is the first embodiment of the groove butt welding method. This welding method is applicable between two low-alloy steel shells, and specifically includes the following steps:

[0042] Step 1.1: Set a first groove 101 on the inner wall 108 of the annular seam of the low-alloy steel shell, and set a second groove 102 on the outer wall 109 . The first groove 101 and the second groove 102 are arranged correspondingly, and the axial connection line between the first groove 101 and the second groove 102 is perpendicular to the surface of the low alloy steel shell. In the first embodiment, the first groove 101 and the second groove 102 adopt double-sided U-shaped grooves, wherein the depth of the second groove 102 is greater than the depth of the first groove 101 .

[0043] Step 1.2. After the two low-alloy steel shells are butted, firstly, in the first groove 101 located on the inner side wall, use the first welding rod with a small diameter to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com