Hydraulic oscillation fracturing technology for oil and gas wells

A well hydraulic and process technology, applied in the field of oil and gas well hydraulic oscillating fracturing technology, can solve the problems of slow pressure increase, increase induced stress around fractures, and difficulty in opening natural micro-fractures in reservoirs, and achieve the goal of optimizing fracture shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Perforate the target layer of gas well fracturing stimulation (burial depth 3300m, closure pressure difference between vertical reservoirs is 5MPa);

[0021] Step 2: Select cross-linked liquefied petroleum gas as the fracturing fluid, use Ф88.9mm tubing, and use 4.0m 3 / min displacement for injection;

[0022] Step 3: After the formation ruptures, during the pre-fluid injection process, a total of 10m of fracturing fluid is injected 3 (Note: The amount of front fluid is 100 m 3 ), quickly stop the pump, stop the pump speed (displacement by 4.0m 3 / min to 0) is less than 0.1 seconds;

[0023] Step 4: Wait for 30-60s;

[0024] Step 5: Turn on the pump to 4.0m 3 30m of accumulative fracturing fluid injected per minute 3 , quickly stop the pump, stop the pump speed (displacement by 4.0m 3 / min to 0) is less than 0.1 seconds;

[0025] Step 6: Wait for 30-60s;

[0026] Step 7: Turn on the pump to 4.0m 3 / min displacement accumulatively injected 80m of fractu...

Embodiment 2

[0030] Step 1: Perforate the target layer of gas well fracturing (reservoir temperature is 100°C, buried depth is 3300m, and natural micro-fractures are developed);

[0031] Step 2: Choose carbon dioxide-guar gum foam as the fracturing fluid, use Ф88.9mm tubing, and use 4.0m 3 / min displacement for injection;

[0032] Step 3: After the formation ruptures, during the prefluid injection process, a total of 10m of foam fracturing fluid is injected 3 (pre-fluid volume is 100m 3 ), pump stop, pump stop speed (displacement by 4.0m 3 / min to 0) is less than 0.1 seconds;

[0033] Step 4: Wait for 30-60s;

[0034] Step 5: Turn on the pump to 4.0m 3 20m of foam fracturing fluid is injected accumulatively at the displacement per minute 3 , quickly stop the pump, stop the pump speed (displacement by 4.0m 3 / min to 0) is less than 0.1 seconds;

[0035] Step 6: Wait for 30-60s;

[0036] Step 7: Turn on the pump to 4.0m 3 30m of foam fracturing fluid is injected accumulatively per ...

Embodiment 3

[0045] It is basically the same as in Example 1, except that the gas well is subjected to fracturing reconstruction.

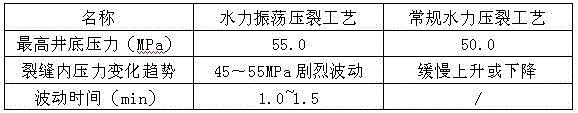

[0046] The comparison between the hydraulic oscillation fracturing process of the present invention and the conventional fracturing process is shown in Table 1 and Table 2, wherein the effects of Embodiment 1 and Embodiment 3 are the same.

[0047] Example 1 Comparison between hydraulic oscillation fracturing technology and conventional fracturing technology (Table 1)

[0048]

[0049] Example 2 Comparison between hydraulic oscillation fracturing technology and conventional fracturing technology (Table 2)

[0050] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com