Full refractory structure supporting lattice brick furnace body structure and masonry process method

A technology of structural support and furnace body structure, applied in the direction of brick blast furnaces, etc., can solve the problems of harsh working environment, labor and man-hours, manual removal, etc., to improve heat storage capacity, high temperature resistance performance, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

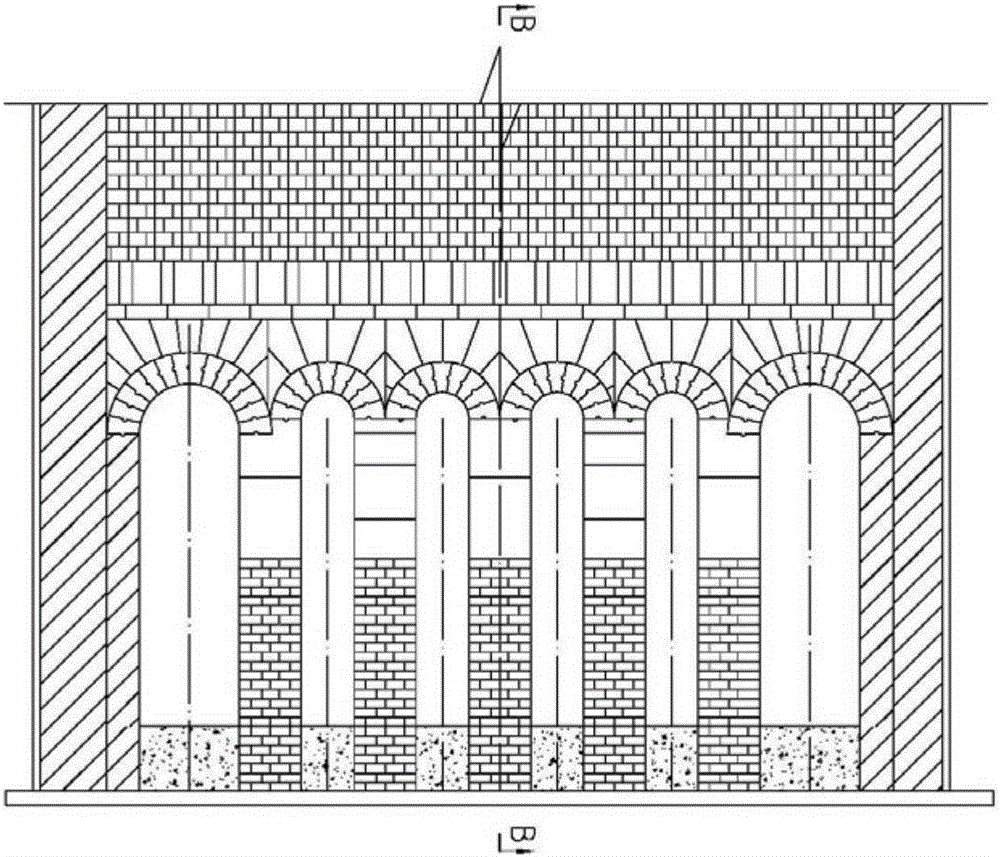

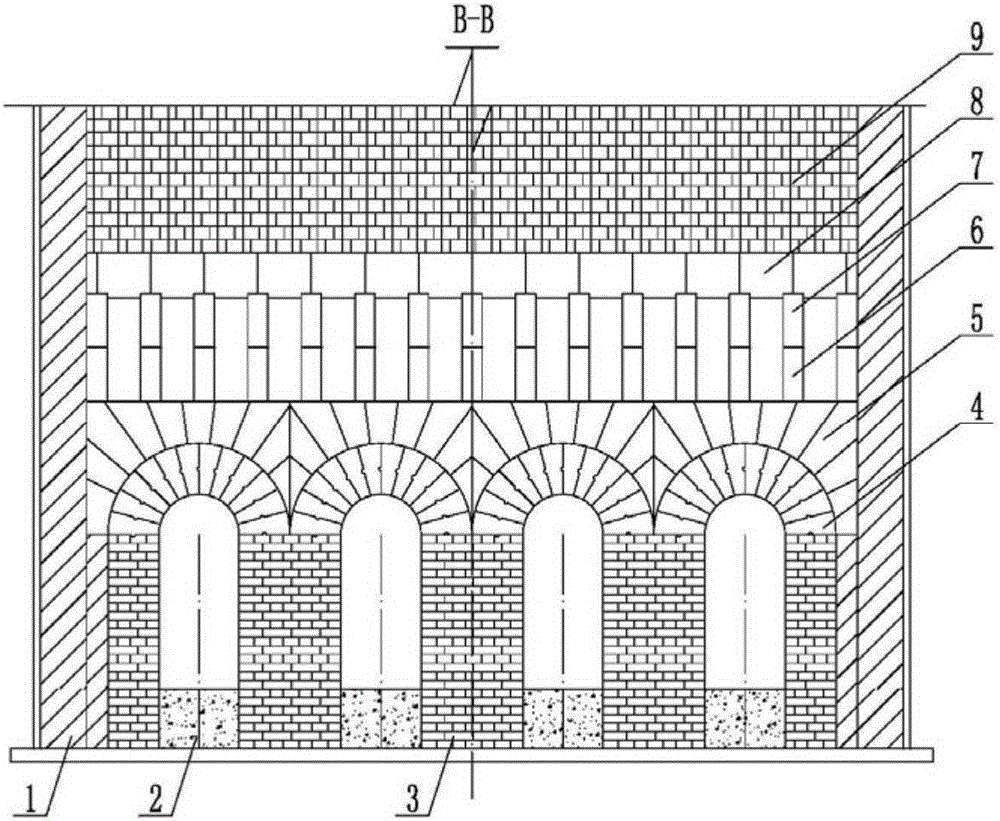

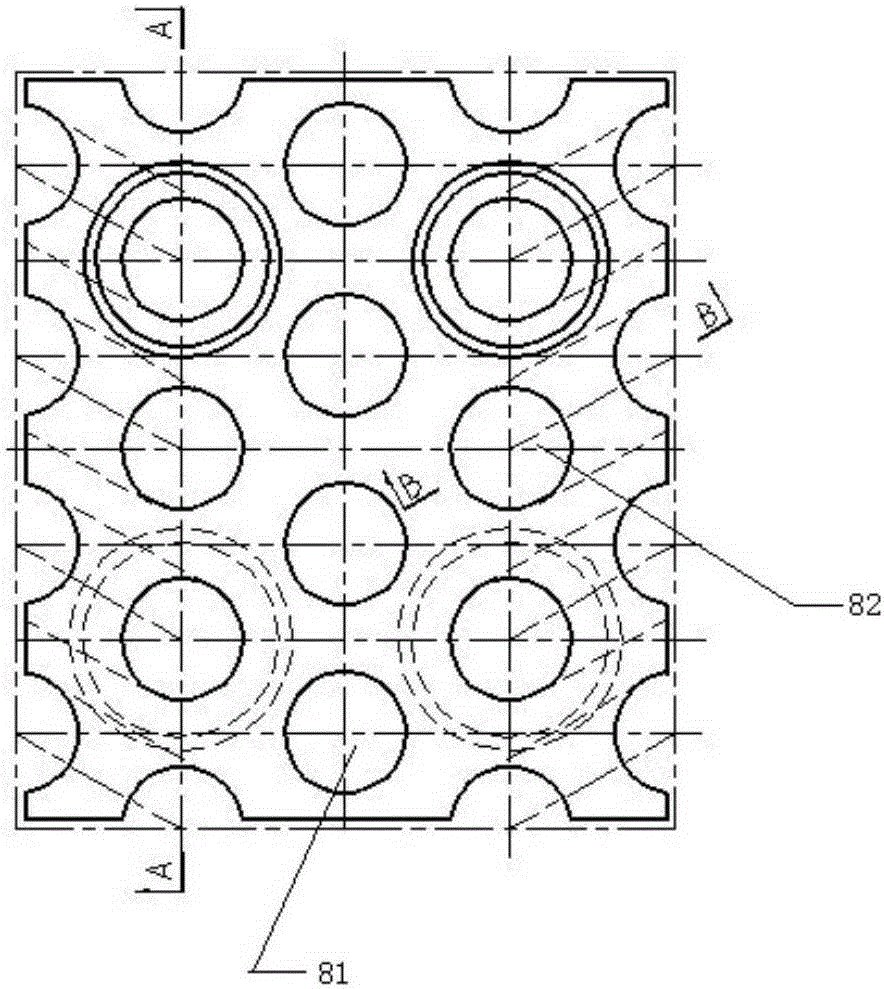

[0030] Such as figure 1 , figure 2 As shown, the all-refractory structure supports the lattice brick furnace body structure, including the furnace bottom plate 1, the upper surface of the furnace bottom plate 1 is a square pillar 3 built with refractory bricks, and the heat-resistant concrete 2 is poured between the square pillars 3. The concrete 2 and the square pillar 3 form an integral body, the upper surface of the square pillar 3 is a masonry refractory primary arched beam, and the upper surface of the primary arched beam is a masonry secondary arched beam of refractory material along the vertical direction of 90°. The transition brick 8 is placed on the secondary arch beam, and the checker brick 9 is placed above the transition brick 8.

[0031] The primary arched beam is transversely connected and consists of arched bricks 4 and arched protective bricks 5 built on the arched bricks. The arched bricks 4 are naturally wedged tightly in the radial direction, and bosses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com