Diesel engine rack single-piece double-face double-arc synchronous gas shielded welding process

A double-sided double-arc welding process technology, applied to welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of reduced production efficiency, low pass rate, and increased high-temperature areas of the workpiece, so as to facilitate welding and ensure weld seams pass rate and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

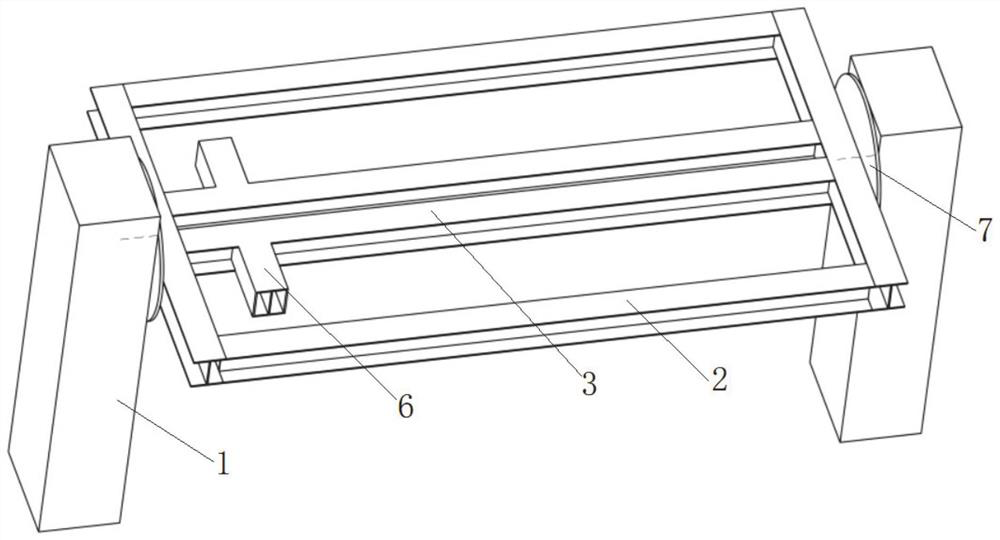

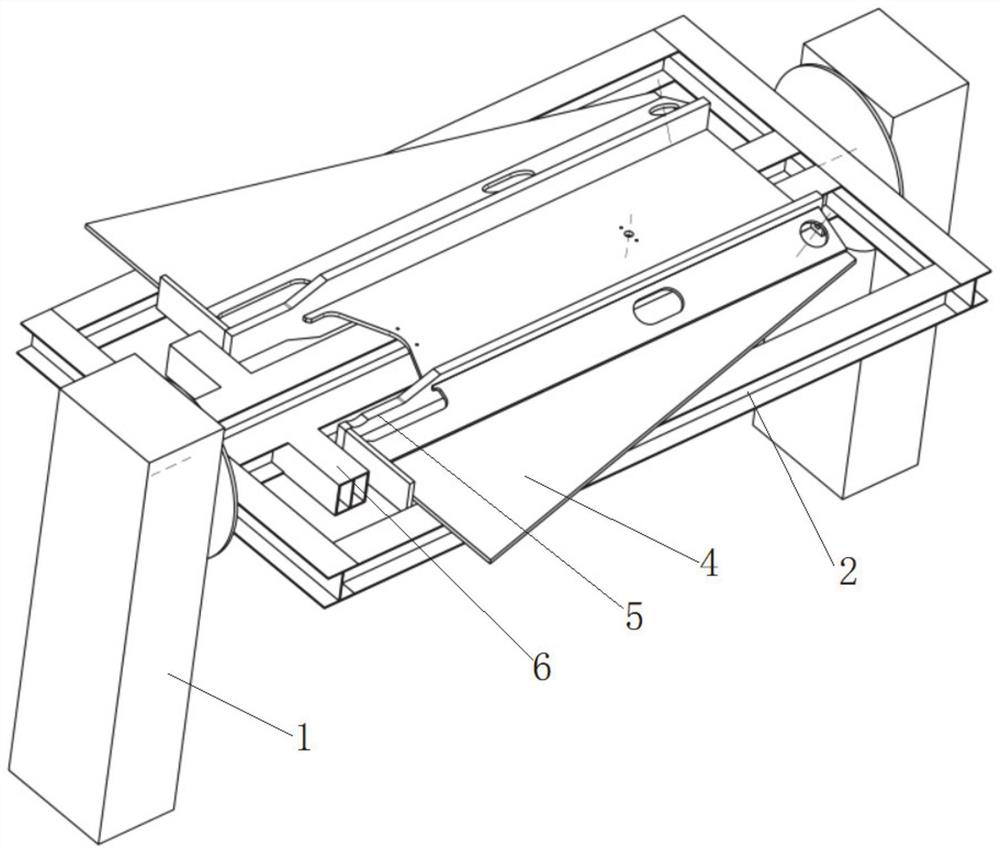

[0040] In a typical embodiment of the present invention, refer to figure 1 As shown, a single-piece double-sided double-arc synchronous gas-shielded welding welding process for a diesel engine frame includes the following content:

[0041] Support the single piece of diesel engine frame through tooling;

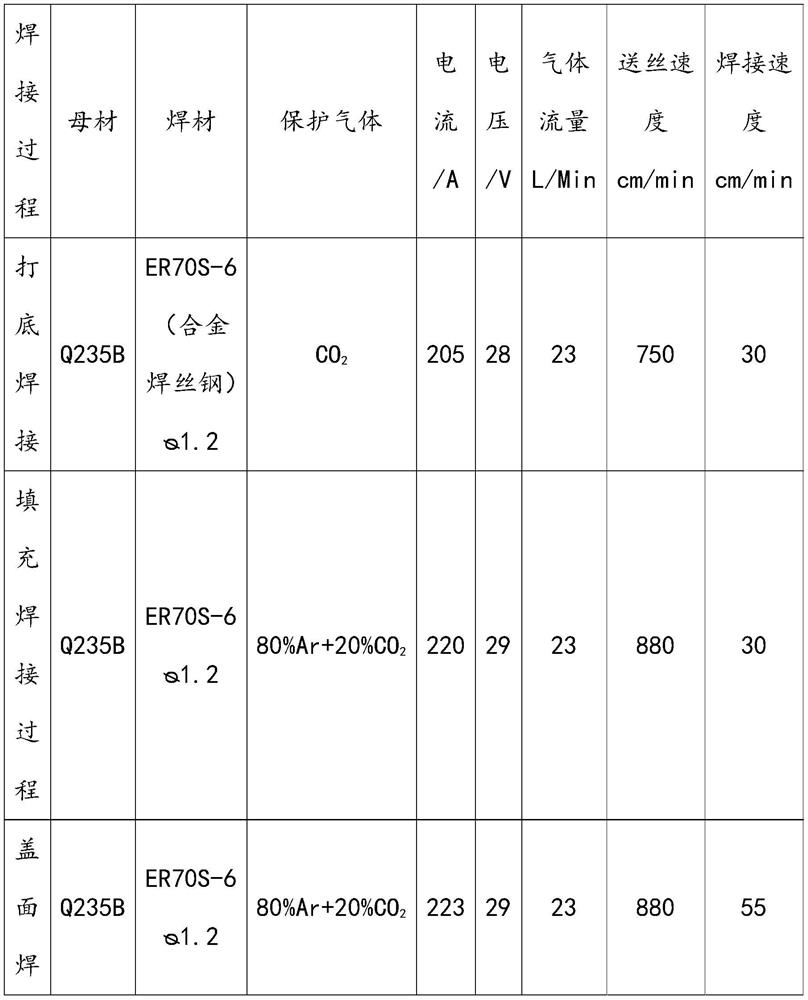

[0042] The single piece is welded with the first set current, and the shielding gas is used to protect the base metal during the welding process to ensure the melting of the base metal;

[0043] After the bottom welding is completed, the single piece is filled and welded with the second set current, and double gas is used for protection during the filling welding process;

[0044] After the filling welding is completed, cover the single piece with the third set current for cover welding. During the cover welding process, the set ratio of argon and carbon dioxide is used as the shielding gas, so that there is no welding during the forming and welding process of each layer of ...

Embodiment 2

[0065] This embodiment provides a diesel engine frame single-piece double-sided double-arc synchronous gas-shielded welding welding process. For the single-piece diesel engine frame, the protective gas is used to protect the base metal during the bottom welding process to ensure that the base metal of the bottom is melted and filled. In the process of welding and cover welding, the proportion of argon and carbon dioxide is used as the shielding gas, so that there is no welding spatter in the forming and welding process of each layer of welds. During the root welding, filling welding and cover welding, the welding current All are different.

[0066] In the welding process provided in this embodiment, except for the tooling, the relevant content is the same as that in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com