A processing method of titanium-steel clad plate based on transition layer control

A processing method and technology for composite plates, which are applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of large accumulated heat input, complicated welding process, low welding speed, etc., to reduce heat input and simplify existing Welding technology, the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] refer to figure 1 , 2, which is the first embodiment of the present invention, which provides a method for processing a titanium-steel clad plate 101 based on transition layer control. .

[0035] The above-mentioned full penetration welding method of titanium steel clad plate 101 includes the following steps:

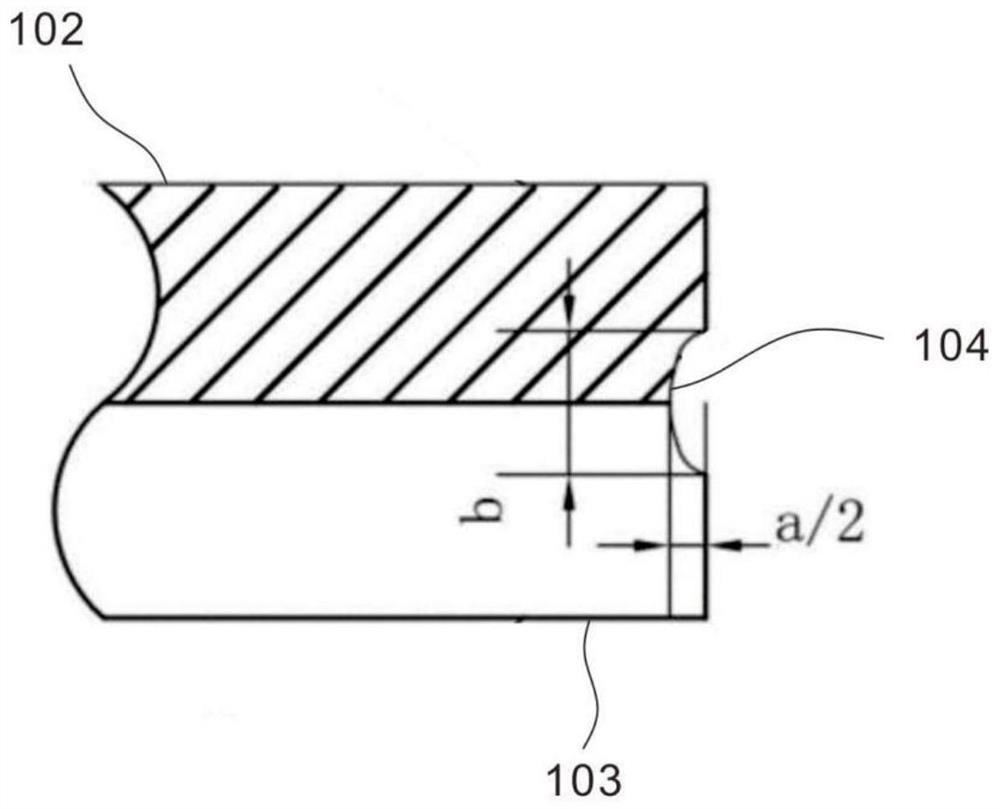

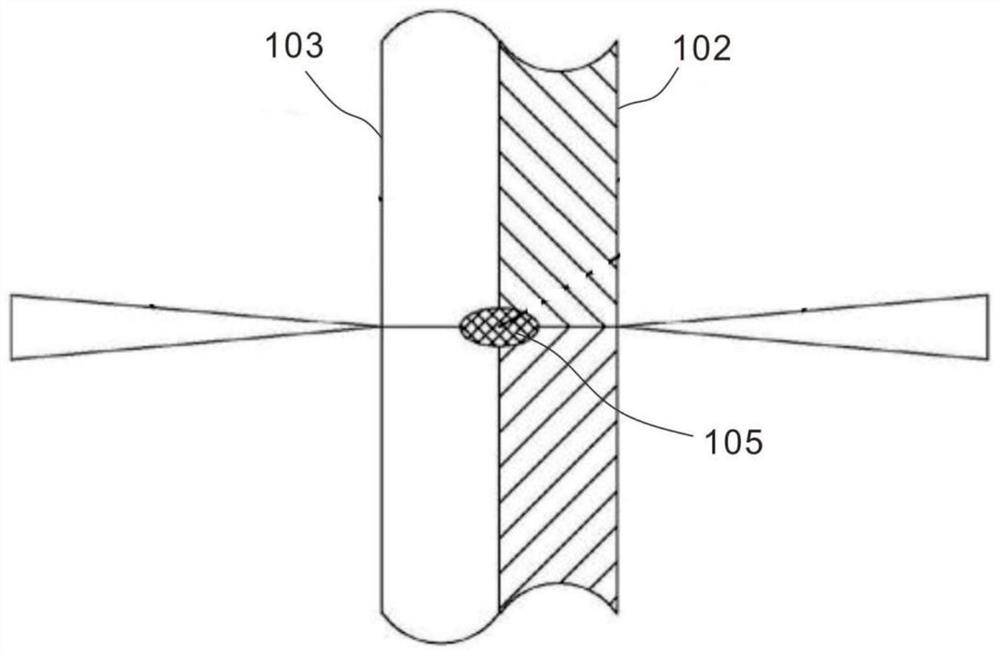

[0036] 1), processing the welding groove 104: at the composite transition line of the welding section of the titanium steel composite plate 101 to be welded, the processing section is a semi-elliptical groove along the length direction of the composite transition line, and the depth of the groove is the semi-elliptical groove 1 / 2 of the short axis a, the long axis b of the semi-ellipse is perpendicular to the joint surface of the titanium cladding 102 and the steel base layer 103 of the titanium-steel clad plate 101 to be welded, and the short axis a of the semi-ellipse is 1-1.6mm , the long axis b=1-2mm; the titanium steel composite plate 101 to be welded aft...

Embodiment 2

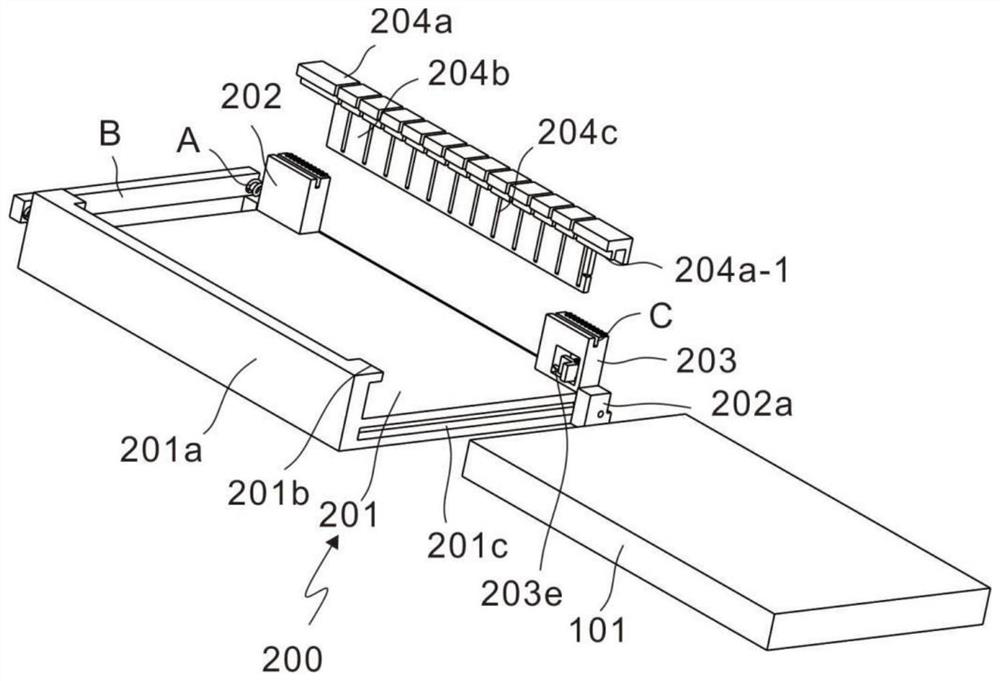

[0045] refer to Figures 3 to 6 , is the second embodiment of the present invention. This embodiment is based on the previous embodiment. The clamping and cutting mechanism 200 includes a bottom plate 201 , a first positioning block 202 , a second positioning block 203 and a cutting adjustment plate 204 .

[0046] The bottom plate 201 is a square structure, the first positioning block 202 and the second positioning block 203 are fixedly arranged on both ends of the upper side of the bottom plate 201, specifically at the two end feet on the upper side of the bottom plate 201, and the cutting adjustment plate 204 is located on the first side. A positioning block 202 and the second positioning block 203 are mounted on the same side of the first positioning block 202 and the second positioning block 203 and are slidably connected.

[0047] Since there is a certain space distance between the first positioning block 202 and the second positioning block 203 , the cutting adjustment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com