A method of manufacturing an aluminum alloy conductive rod

A manufacturing method and technology of conductive rods, which are applied in the direction of manufacturing tools, conductors, circuits, etc., can solve the problems of welding quality of large guide heads and guide rods, and achieve the goals of improving the one-time pass rate, dense weld structure, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

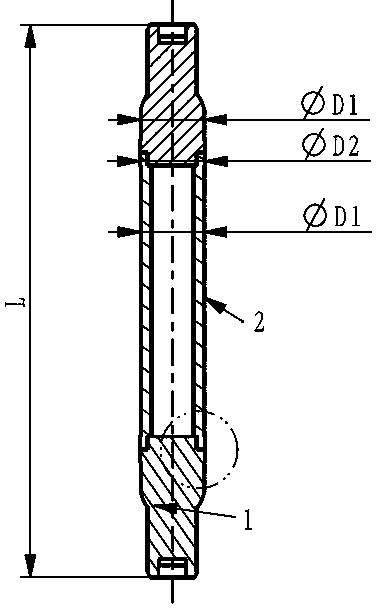

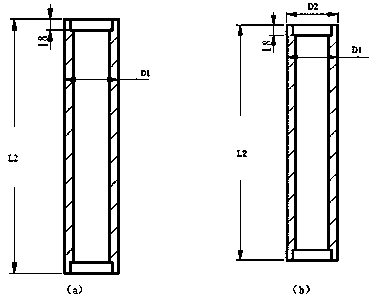

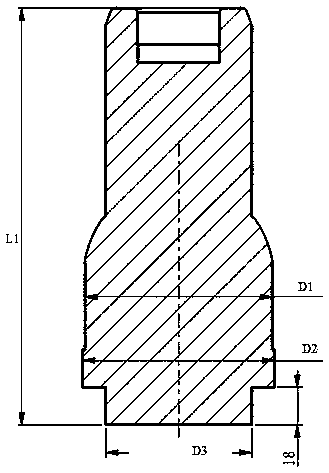

[0026] Describe the present invention below in conjunction with specific example, as Figure 1~5 As shown, this example manufactures a conductive rod with a diameter of 90mm and a length of 1000mm. figure 1 The conductive rod shown is composed of three parts: two guide heads 1 and a guide rod 2, the guide rod 2 is extruded from aluminum alloy to form an aluminum alloy tube section; the guide head is formed by mechanical turning of aluminum alloy. The guide head 1 and the guide rod 2 are welded by friction stir welding technology, figure 2 (a) is a schematic diagram before reaming, figure 2 (b) is a schematic diagram after reaming, and the specific steps are as follows:

[0027] Step 1: Manufacture of the guide head of the conductive rod; the guide head is machined with 6-series aluminum alloy material according to the size requirements specified in the drawing, and the surface roughness of the guide head is 0.8, which should meet the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Concentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com