Welding structure of hydraulic cylinder jacket and processing technology thereof

A welding structure and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve problems such as damage to seals and affecting the service life of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

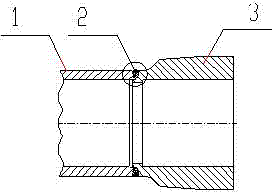

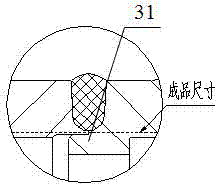

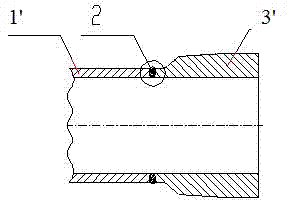

[0019] Such as figure 1 As shown, a hydraulic cylinder sheath welded structure, which includes a cylinder 1 and a sheath 3; cylinder 1 has an inner hole seam at one end, and a positioning cylinder 31 at one end of the sheath 3, and the positioning cylinder 31 is cylindrical. The inner diameter is smaller than the inner diameter of the sheath 3, and the outer side of the positioning cylinder 31 is provided with an outer circular seam; the positioning cylinder 31 of the sheath 3 is inserted into the inner hole seam of the cylinder body 1, and the radial connection formed between the cylinder body 1 and the two ends of the sheath 3 There is a U-shaped weld 2 on the seam, and the distance between the bottom of the weld 2 and the outer surface of the positioning cylinder 31 is 1 mm to ensure complete penetration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com