Oil refining equipment for waste plastics

A technology for waste plastics and equipment, applied in the field of waste plastic oil refining equipment, can solve the problems of reducing oil refining quality, occupying furnace space, reducing melting efficiency, etc., and achieves the effect of improving heating efficiency, ensuring filling amount, and increasing heating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

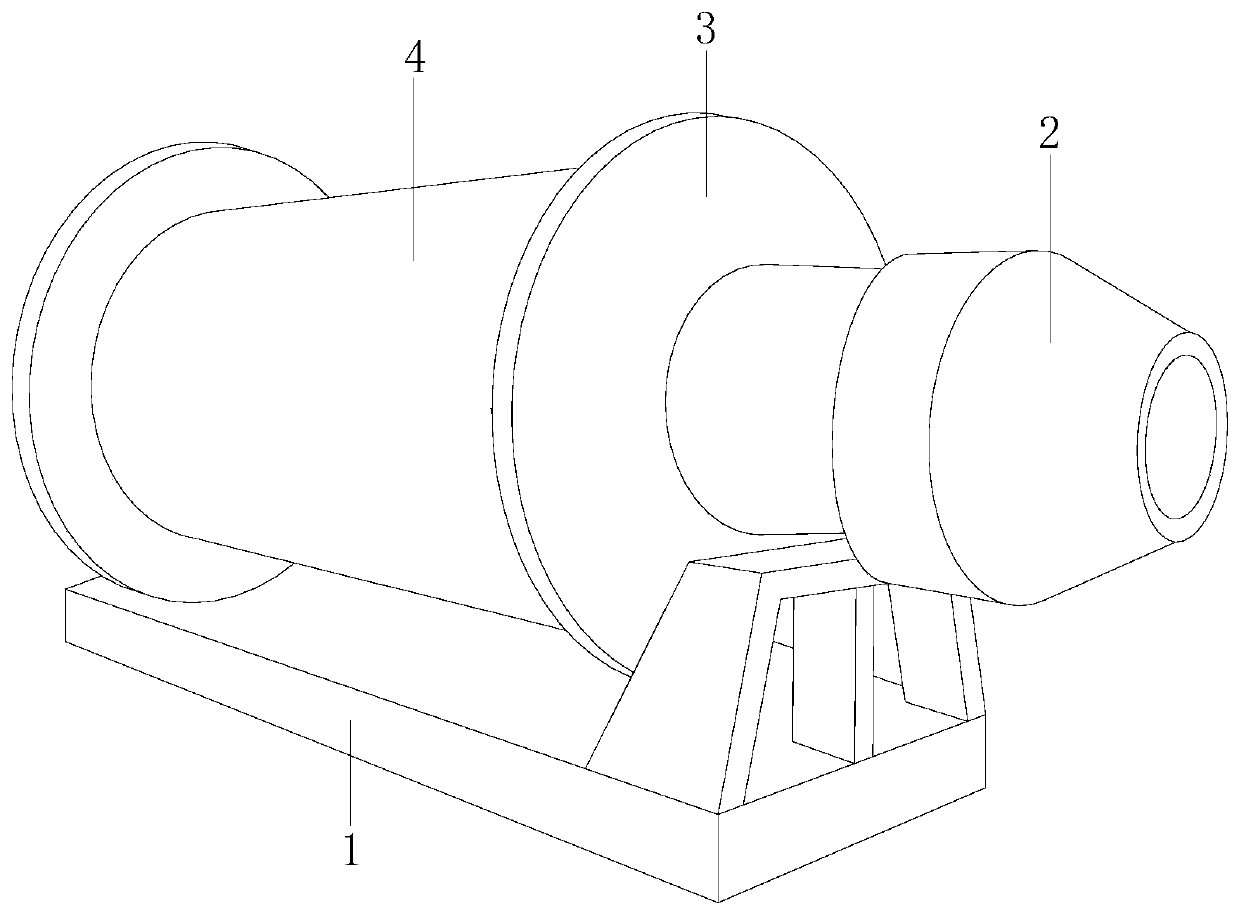

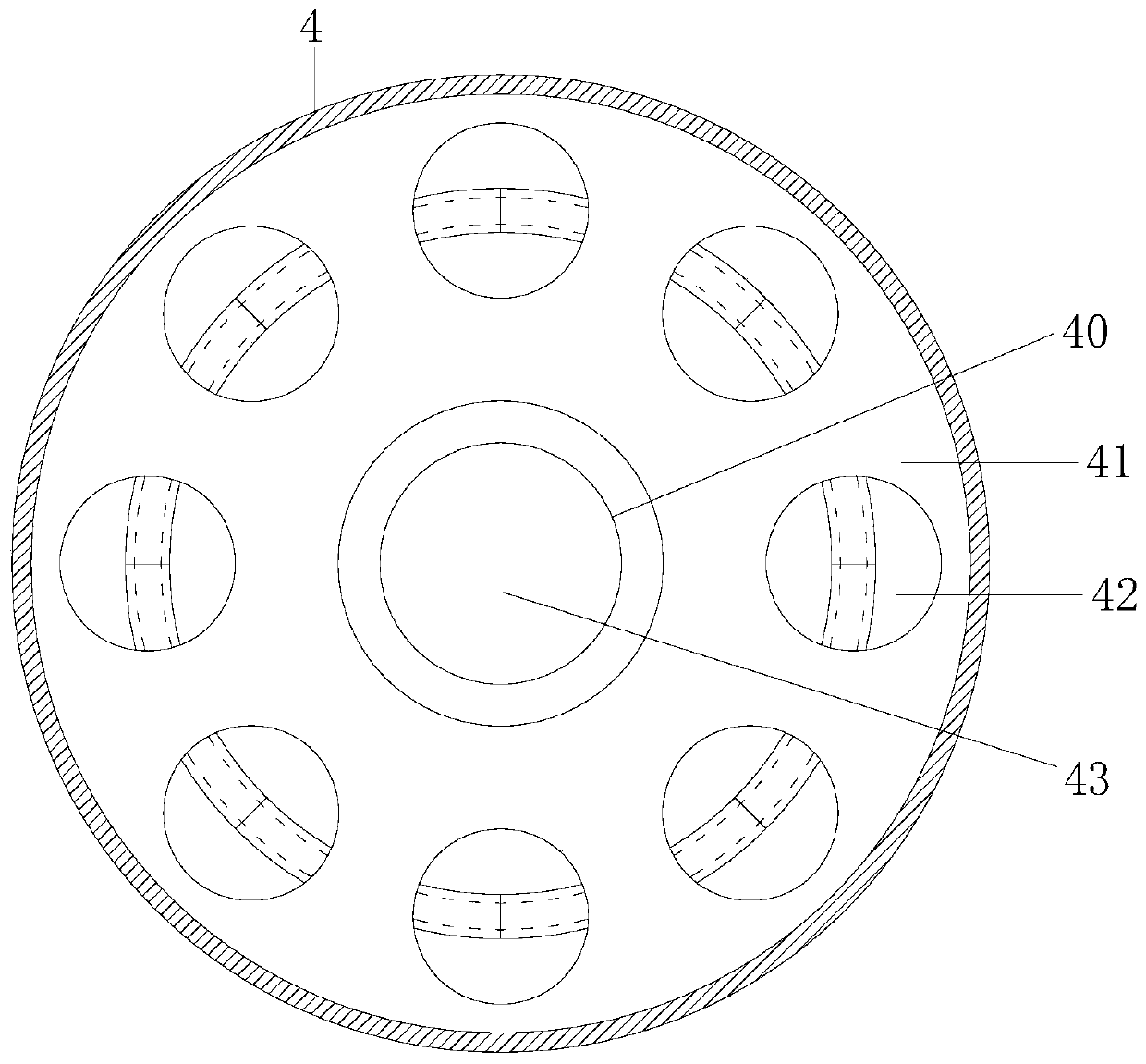

[0026] Example 1 see Figure 1-2 , the present invention provides a technical scheme of waste plastic oil refining equipment: its structure includes a chassis 1, a feeding pipe 2, a machine plate 3, and a machine barrel 4, the chassis 1 is locked with the machine plate 3, and the machine plate 3 is locked with the machine plate 3. The barrel 4 is welded and the two are connected. The feed pipe 2 is connected to the machine plate 3 shafts. The barrel 4 is composed of a barrel ring 40, a refining barrel 41, a refining circle 42, and a barrel mouth 43. The waste is concentrated in the refining barrel 4. The middle part of cylinder 41 and refining circle 42 is relatively densely filled to ensure the filling volume. The refining cylinder 41 is provided with a cylinder mouth 43, and the cylinder ring 40 is connected with the refining cylinder 41. The refining cylinder 42 is installed on the refining cylinder. 41, the heating layer is added, the heating efficiency is improved, and th...

Embodiment 2

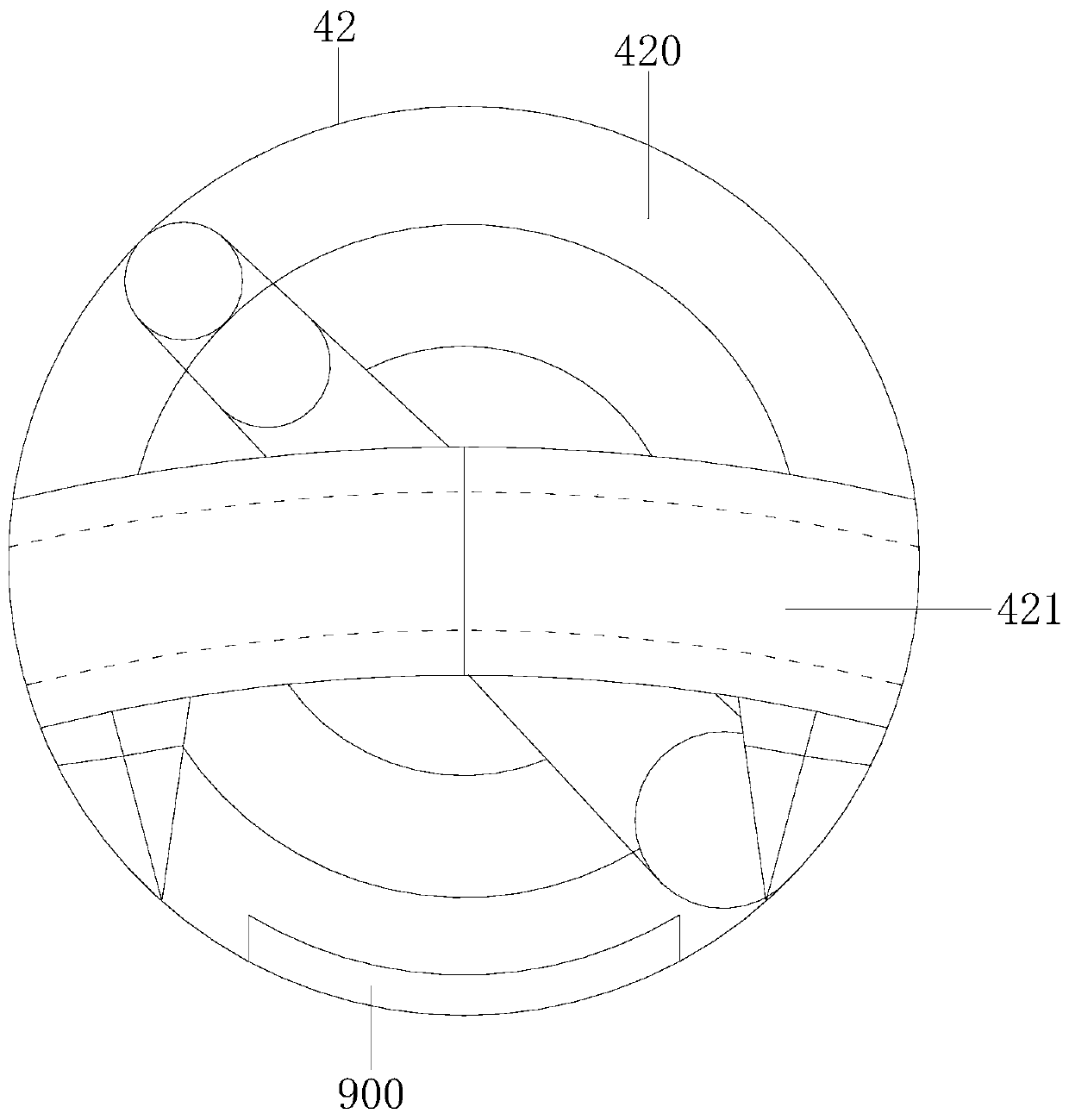

[0028] Example 2 see Figure 3-6 , the present invention provides a technical solution for waste plastic oil refining equipment: the refining circle 42 includes a pendulum structure 420 and an arc track structure 421, the refining circle 42 can be assembled into a complete circle, and the melt will not splash Inside the refining cylinder 41, the molten metal adhered to the refining circle 42 itself falls off through vibration, and the pendulum structure 420 is fastened to the arc rail structure 421, and the pendulum structure 420 realizes transmission by sensing gravity, and the arc The rail structure 421 includes a rail round frame 4210, a liquid reservoir 4211, and an arc track 4212. The rail round frame 4210 is locked with the liquid reservoir 4211, and the arc rail 4212 is installed on the rail round frame 4210. The liquid storage The container 4211 fits with the arc track 4212. The liquid reservoir 4211 includes a push plate 500, a support plate 501, and a liquid storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com