A solid oxide fuel cell connector structure and assembly method thereof

A solid oxide and fuel cell technology, which is applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor sealing integrity, poor joint sealing, and low reliability, and achieve accurate pressure application, reduced stiffness, and successful lifting rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

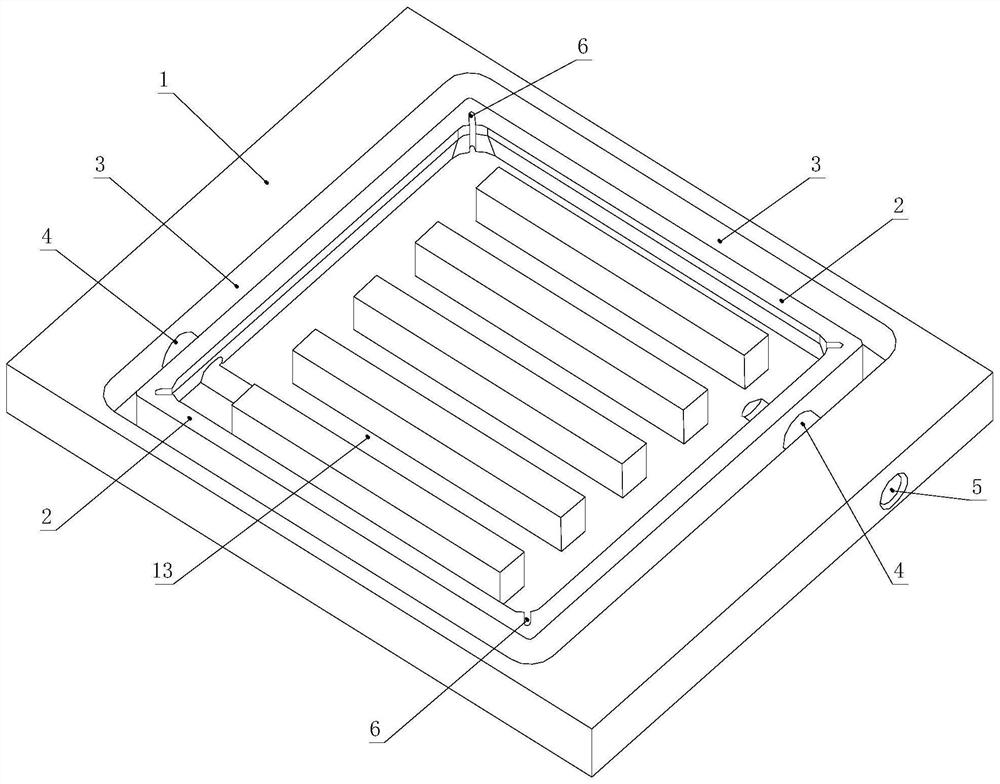

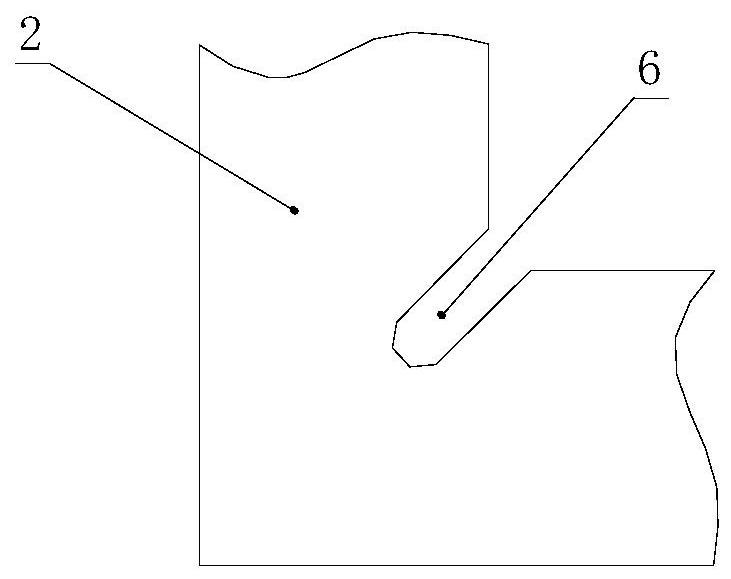

[0045] combine figure 1 , figure 2 and image 3 , a structure of a solid oxide fuel cell connecting body 1, comprising a sealing protrusion 2 arranged on the connecting body 1, the connecting body 1 is also provided with a stress relief groove 3, and the stress relief groove 3 is sealed around the The outer side of the protrusion 2 is arranged; the stress relief groove 3 is provided with a connecting pipe 4 , and the connecting pipe 4 is used to connect the air guide hole 5 and the cavity enclosed by the sealing protrusion 2 .

[0046] Specifically, the sealing protrusion 2 is in a closed shape, and air guide holes 5 are provided on both sides of the connecting body 1 to provide fuel or oxidant for the fuel cell; the structural outline of the connecting body and the sealing protrusion 2 The cross-section can be one of square, rectangle, and other polygons, or the above shape with chamfered corners, or a circle or an ellipse. The inner side of the stress relief groove 3 is ...

Embodiment 2

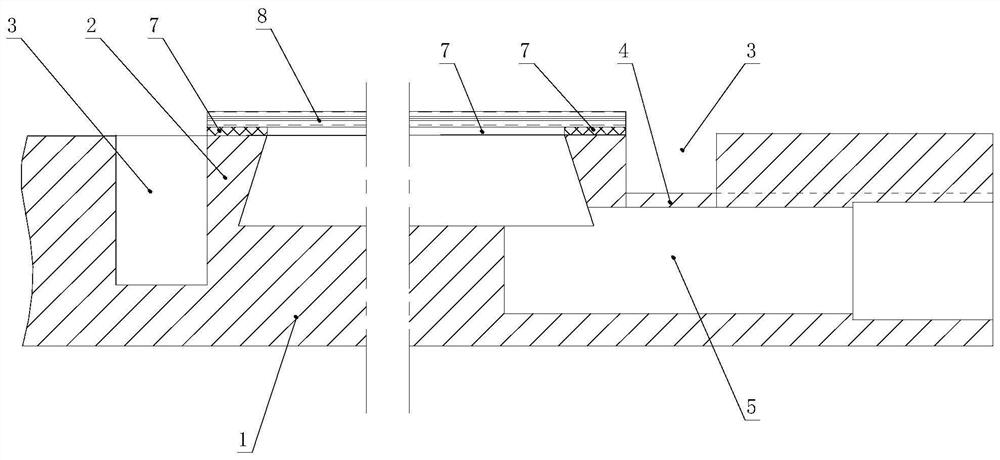

[0059] combine Figure 4 , a method for assembling a solid oxide fuel cell connector and a single cell sheet, comprising the following steps:

[0060] The body of the connector 1 is obtained, and the sealing material 7 is covered on the upper end of the sealing protrusion 2 of the connector 1;

[0061] Cover the single cell sheet 8 on the sealing protrusion 2, so that the single cell sheet 8, the sealing protrusion 2 and the body of the connecting body 1 enclose a cavity;

[0062] Insert the two positioning pieces 9 into the stress relief grooves 3 on the opposite corners of the connecting body 1 to move the single cell 8 to the sealing position, wherein the stress relief grooves 3 are arranged on the connecting body 1 and surround the sealing body 1 Set up from the outside of the connection protrusion 2;

[0063] Place the pressing member 10 on the single cell sheet 8 to position the pressing member 10 by the positioning member 9;

[0064] The pressing member 10 and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com