Hinge for spectacles

A technology for hinges and glasses, applied in glasses/goggles, optics, instruments, etc., can solve the problems of lack of compactness, large demand, etc., achieve simple and economical production, and improve the effect of stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

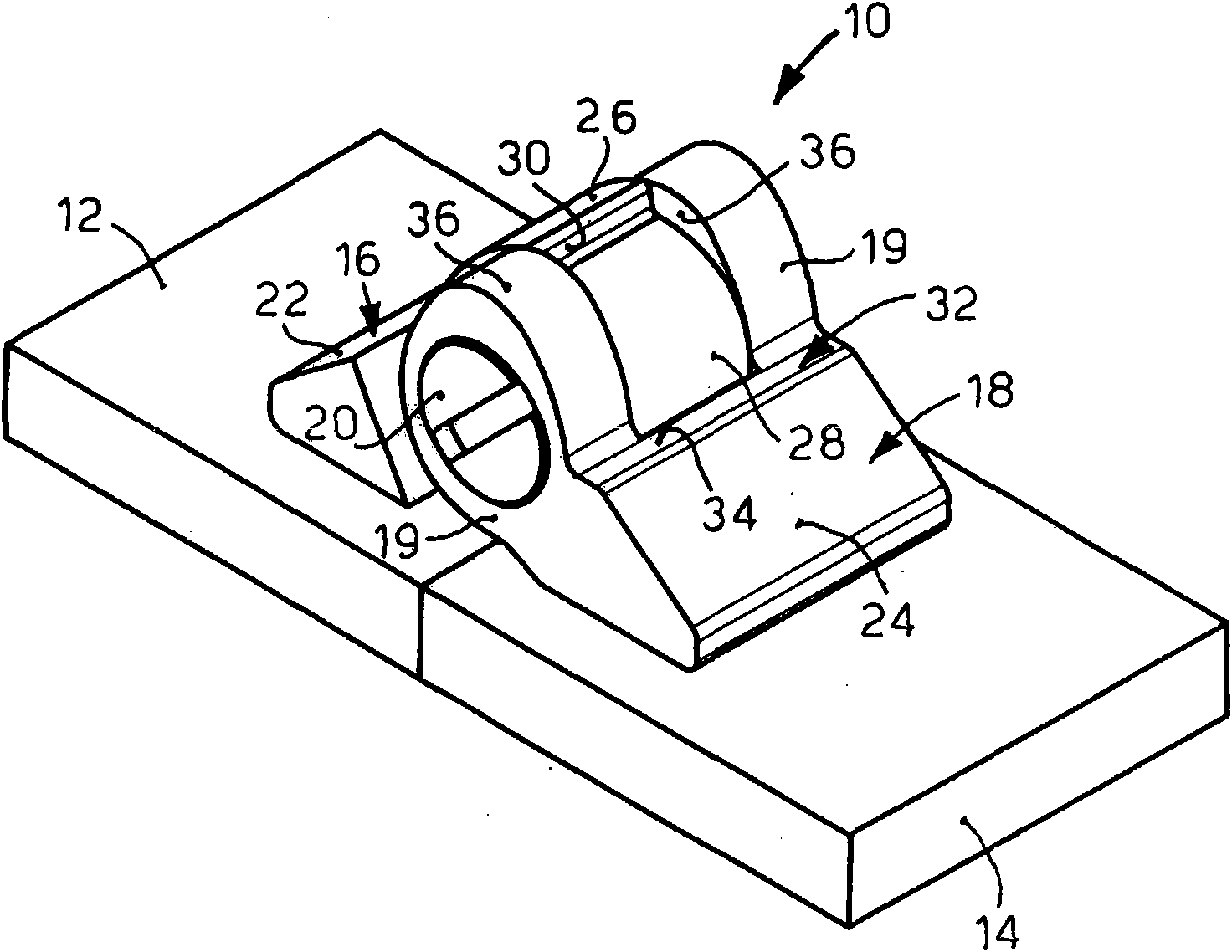

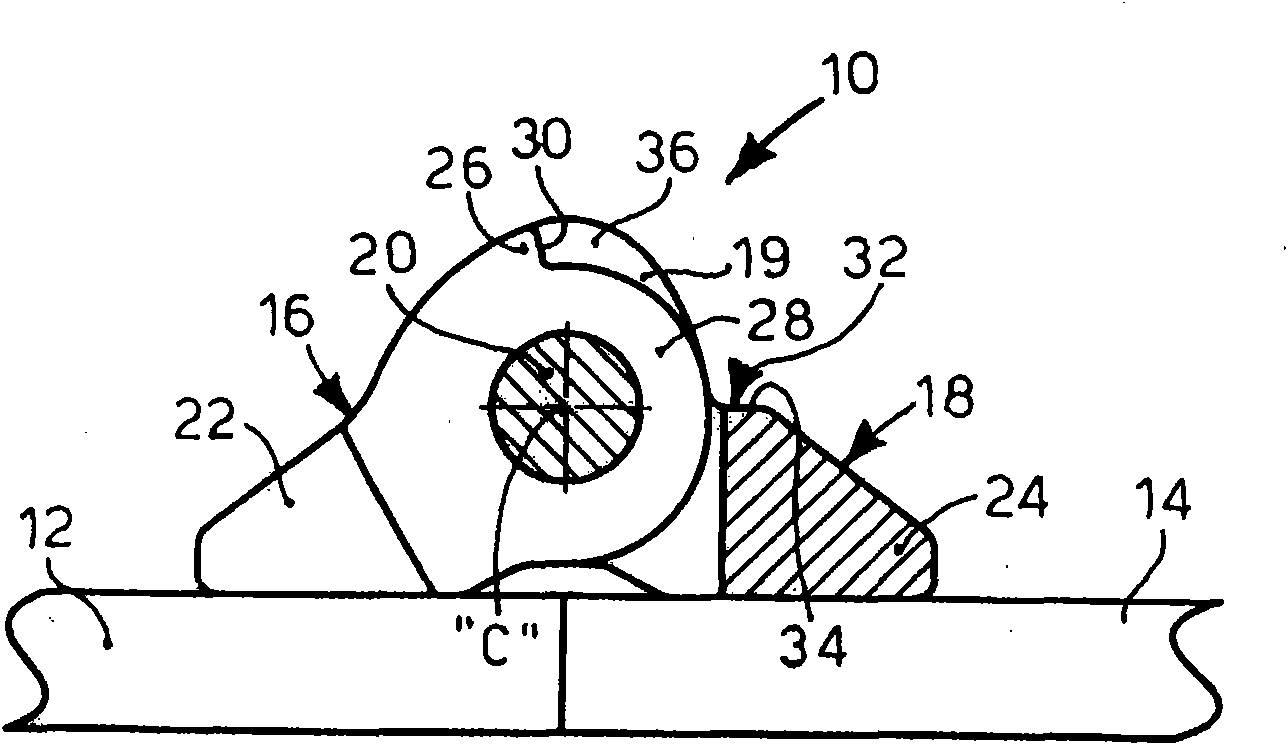

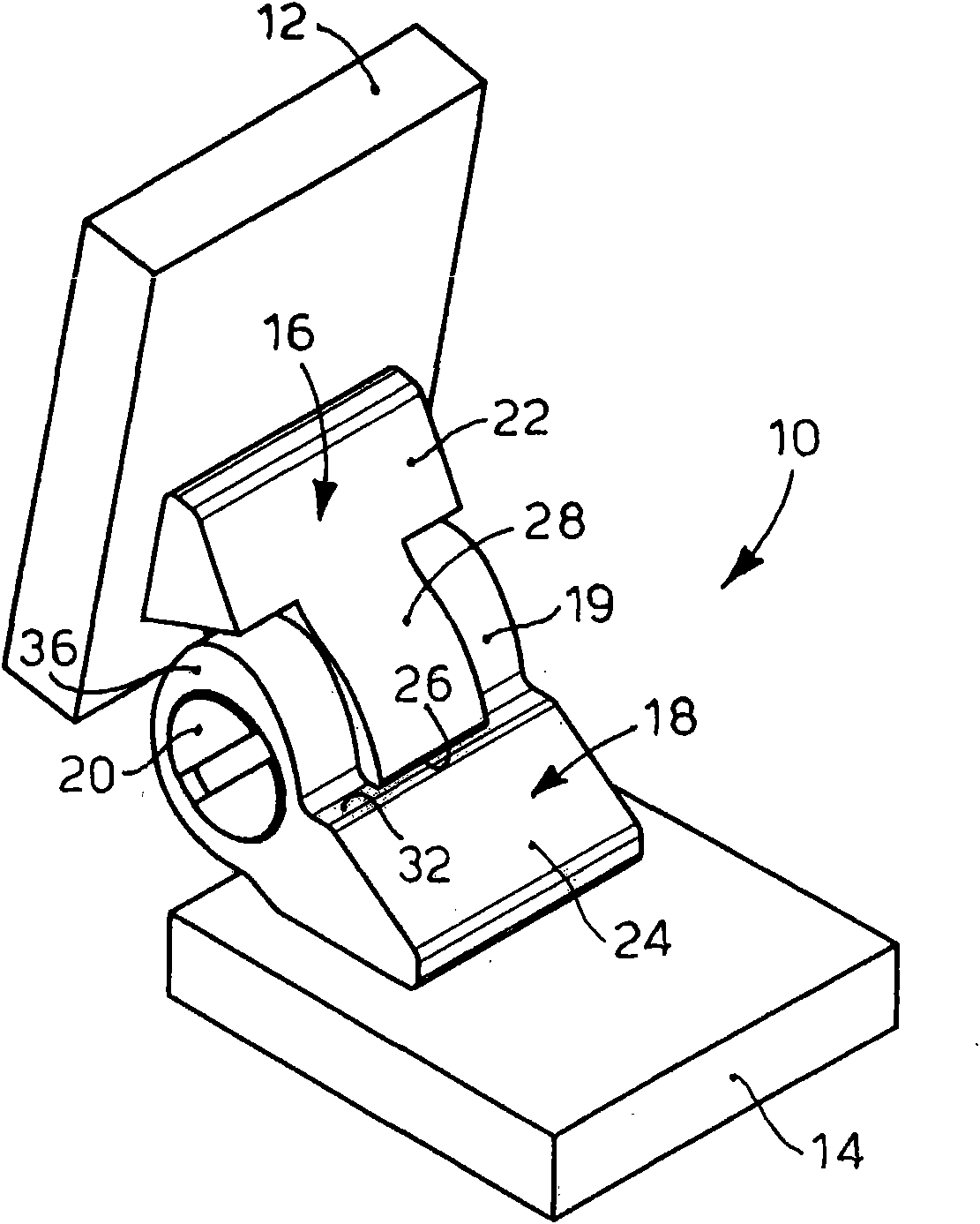

[0040] With reference to the accompanying drawings, the hinge 10 for spectacles according to the present invention is of the type with a mechanical stop and is used to articulate the arm 12 and the lug 14 of the spectacle frame to each other.

[0041] In particular, the hinge 10 of the present invention provides at least one stable closed position of the arm 12 that defines the desired closing angle α to prevent the free end of the arm 12 from coming into contact with the lens of the spectacles.

[0042] Hinge 10 ( figure 1 ) includes two hinged elements, respectively the first hinged element 16 coupled with the arm 12 and the second hinged element 18 coupled with the lug 14 of the glasses, these two hinged elements pass through the pivot center C determined with the Corresponding pins 20, for example screws, are pivotally connected to each other.

[0043] The first hinge element 16 comprises a base body 22 and a hinge eyelet 28 protruding from the base body 22 , through whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com