Lightweight pinch grip hanger

A technology of clothes hangers and clips, which is applied in the direction of clothes hangers, clothespins, textiles and paper making, and can solve problems such as adverse effects on operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

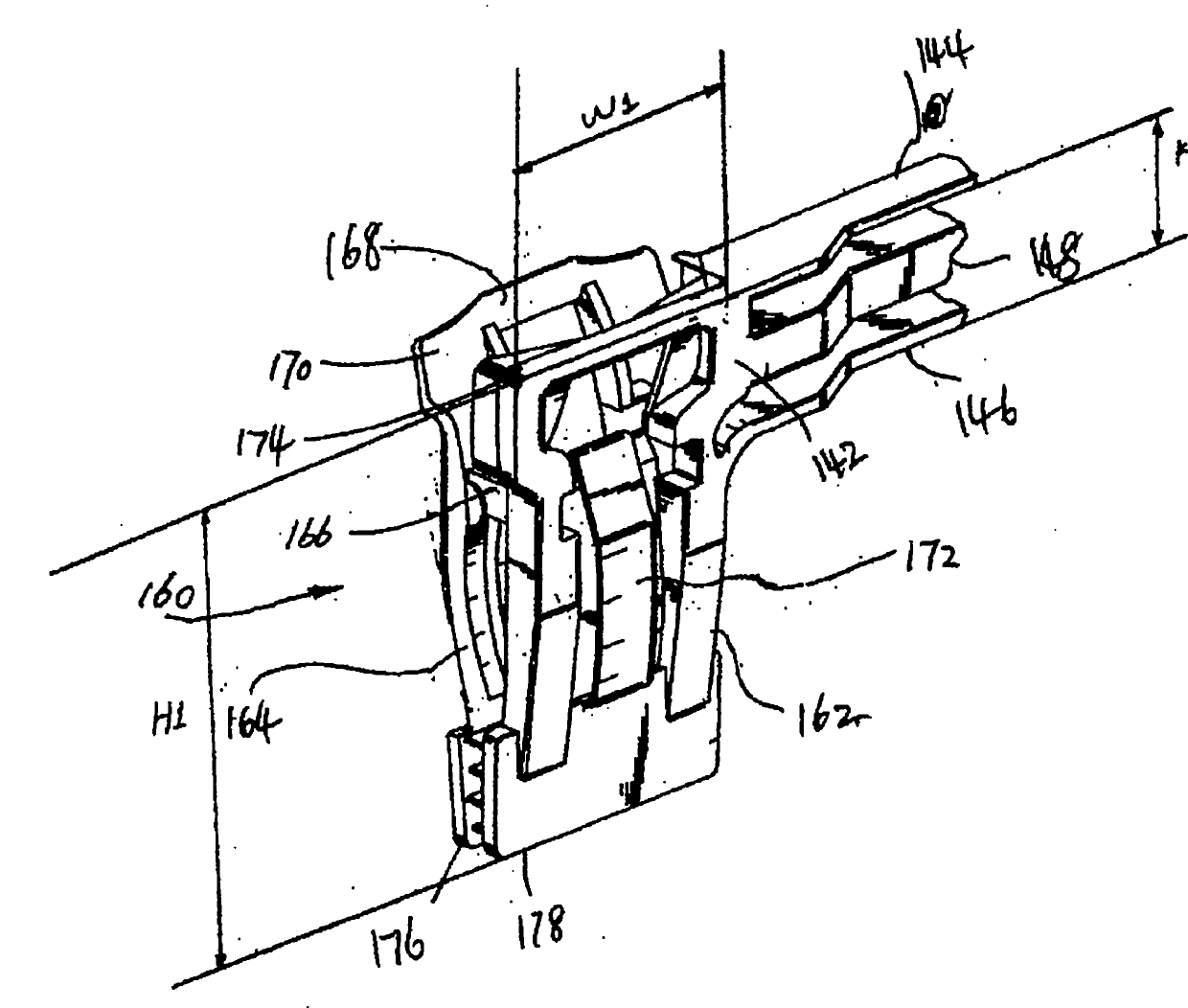

[0033] refer to figure 1 , illustrated is a pinch hanger 100 known in the prior art. The hanger has a hook part 110 and a hanger body 120 connected to the hook part 110 substantially in the middle of the body 120 . The hanger body 120 is substantially symmetrical along the centerline CL of the body, as shown.

[0034] The main body 120 has an upper portion including a centrally located protrusion 130 on which the hook member 110 is rotatably mounted. The protrusion 130 is reinforced by a pair of wings 132 and 134 on opposite sides thereof, which are integrally molded and connected to the main body 120 . Preferably, the pair of wings 132 and 134 are substantially symmetrical to each other with respect to the centerline CL of the hanger body 120 .

[0035]The area of the hanger where the protruding portion 130 and the wings 132 and 134 are disposed and the area of the hanger where the hook member 110 is connected to the main body 120 of the hanger is generally defined as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com