Improved structure of caliper

A caliper and vernier technology, applied in the field of measuring tools, can solve problems such as inaccurate measurement results and excessive lateral clearance of calipers, and achieve the effects of solving inaccurate measurement results, simple design, and eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

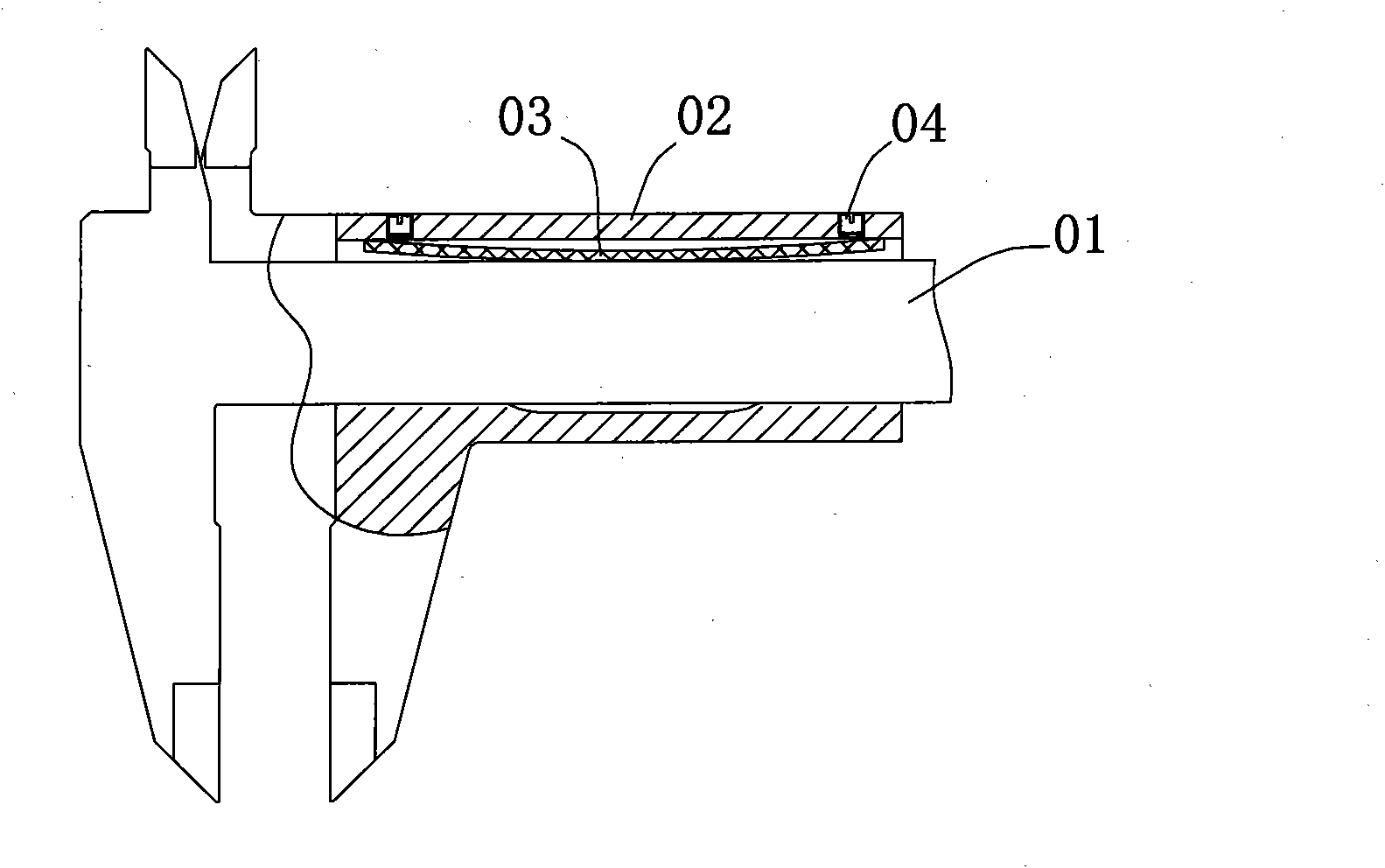

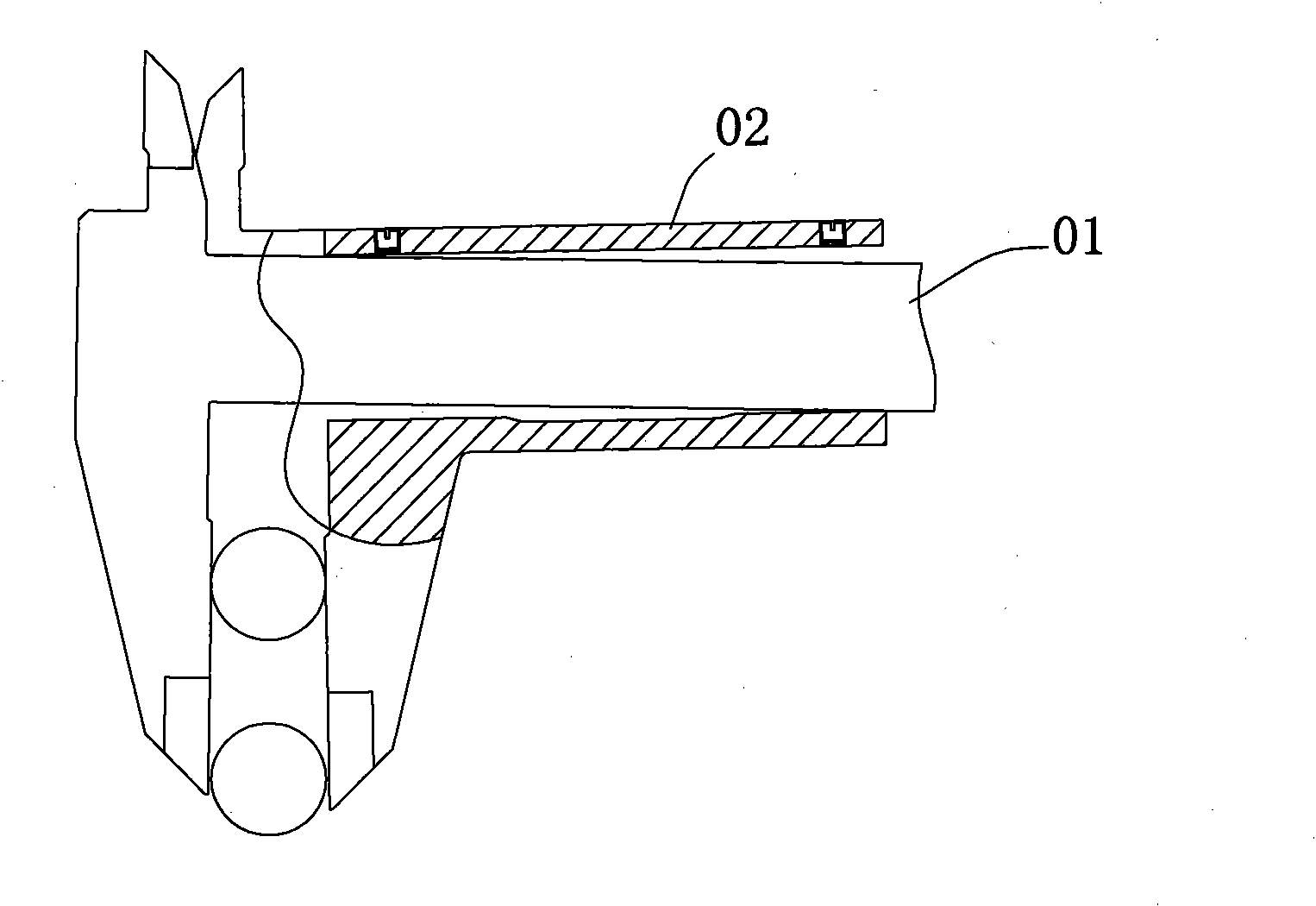

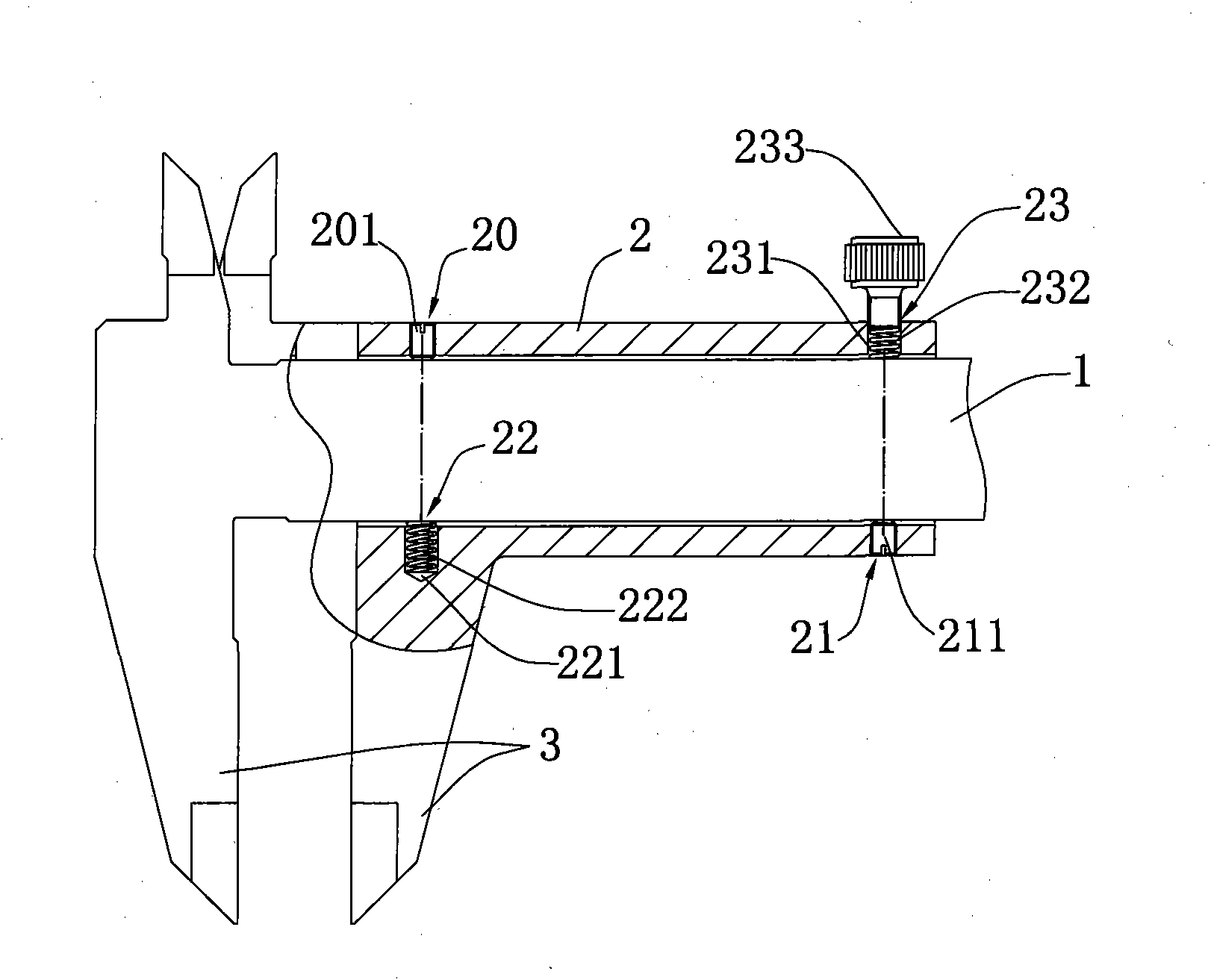

[0021] like image 3 As shown, an improved structure of a caliper comprises a main ruler 1, a vernier ruler 2, a measuring claw 3 arranged on the main ruler 1 and the vernier ruler 2, and a positioning mechanism is provided on the side of the upper end of the vernier ruler 2 close to the measuring claw 3 I 20, the lower end of the vernier scale 2 is provided with a positioning mechanism II 21 which is in a diagonal structure with the positioning mechanism I 20, and the positioning mechanism I 20 and the positioning mechanism II 21 are respectively abutted against the upper end face and the lower end face of the main ruler 1 To limit the lateral displacement of the vernier ruler 2, the side of the lower end of the vernier ruler 2 close to the measuring claw 3 is provided with an elastic pressing mechanism 22 abutting against the lower end face of the main ruler 1, so that the positioning mechanism I 20 and the positioning mechanism II 21 are kept aligned with the main ruler. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com