Direct heating type vacuum welding furnace

A vacuum welding furnace and direct heating technology, applied in welding equipment, electric heating devices, metal processing equipment, etc., can solve the problems of slow speed, difficult to guarantee welding quality, poor heating effect, etc., and achieve high efficiency, good heating effect, The effect of high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

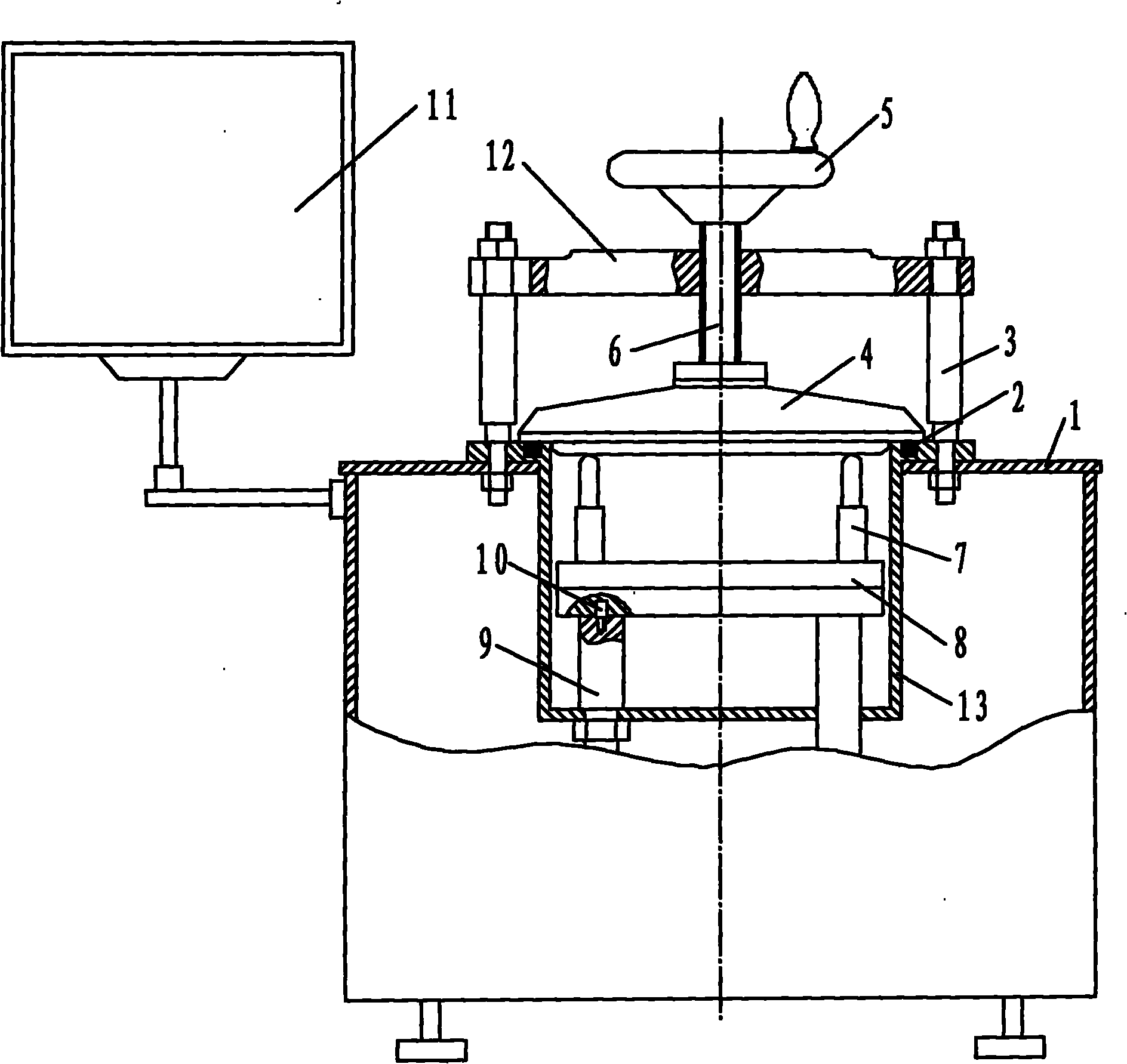

[0015] Such as figure 1 As shown, the vacuum welding furnace of the present invention mainly includes a housing 1, a vacuum chamber 13, an electrode 9, a graphite heating plate 8 and a gland 4, and the vacuum chamber 13 is installed in the housing 1 and fixed together by two columns 3, A connecting body 12 is installed on the column 3 . One end of the connecting body 12 is sleeved on one of the columns, and can rotate around the column. The other end of the connecting body 12 is provided with an opening, which can be stuck on another column, and the connecting body can be made by tightening the nuts on the two columns. 12 are fixed on two uprights. A screw 6 is installed on the connecting body 12 through threaded connection, a handwheel 5 is installed on the upper end of the screw 6, and a gland 4 is installed on the lower end, turning the handwheel 5 makes the screw 6 rotate and move downward, so that the gland 4 is pressed tightly on the The upper end surface of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com