Shuttle ship and running orbit structure of plastic circular weaving machine

A technology of circular looms and shuttle boats, applied to circular looms, looms, textiles, etc., can solve the problems of many wearing parts, high noise, high power consumption, etc., to reduce noise, reduce wearing parts, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed description embodiment below in conjunction with accompanying drawing

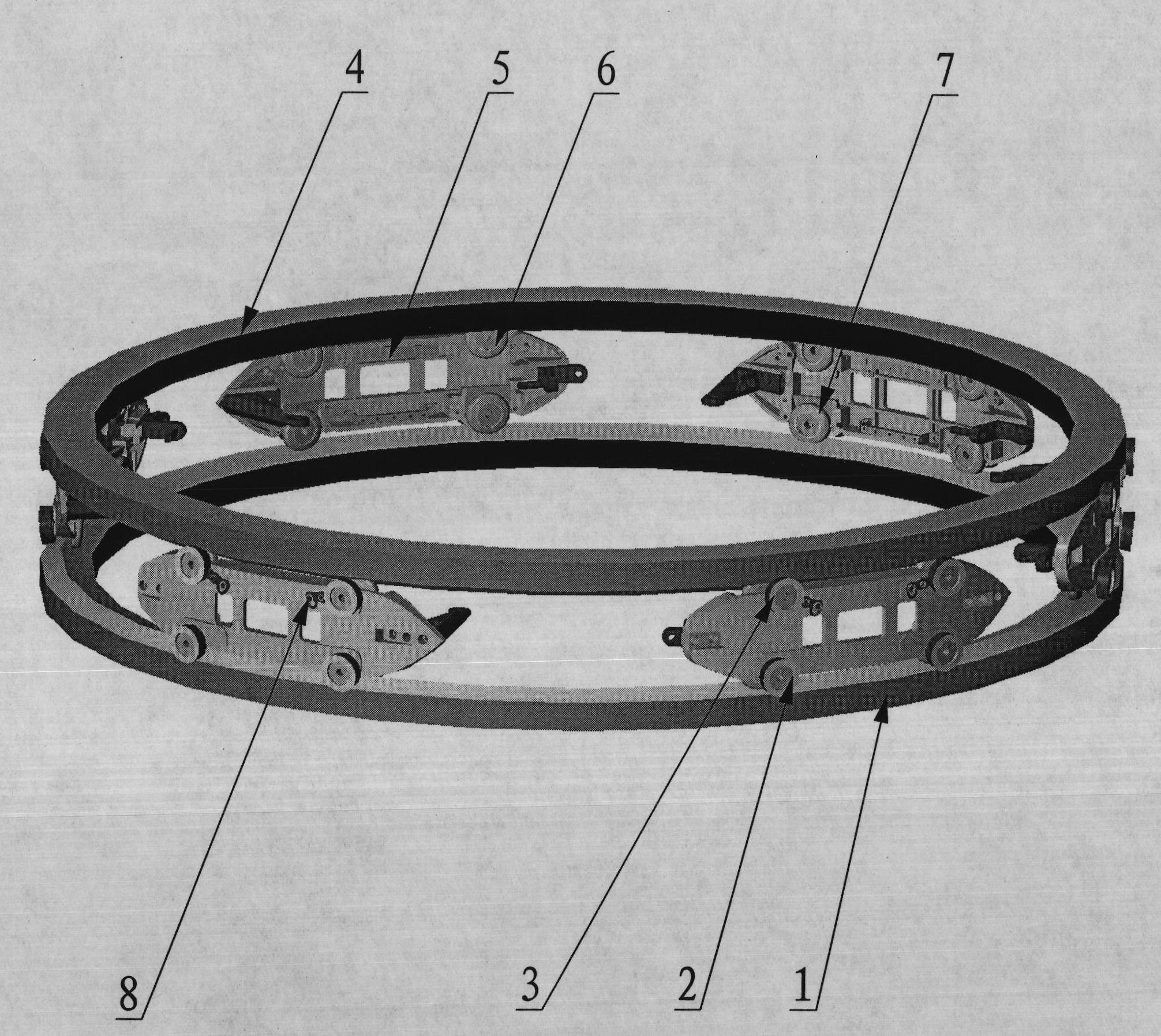

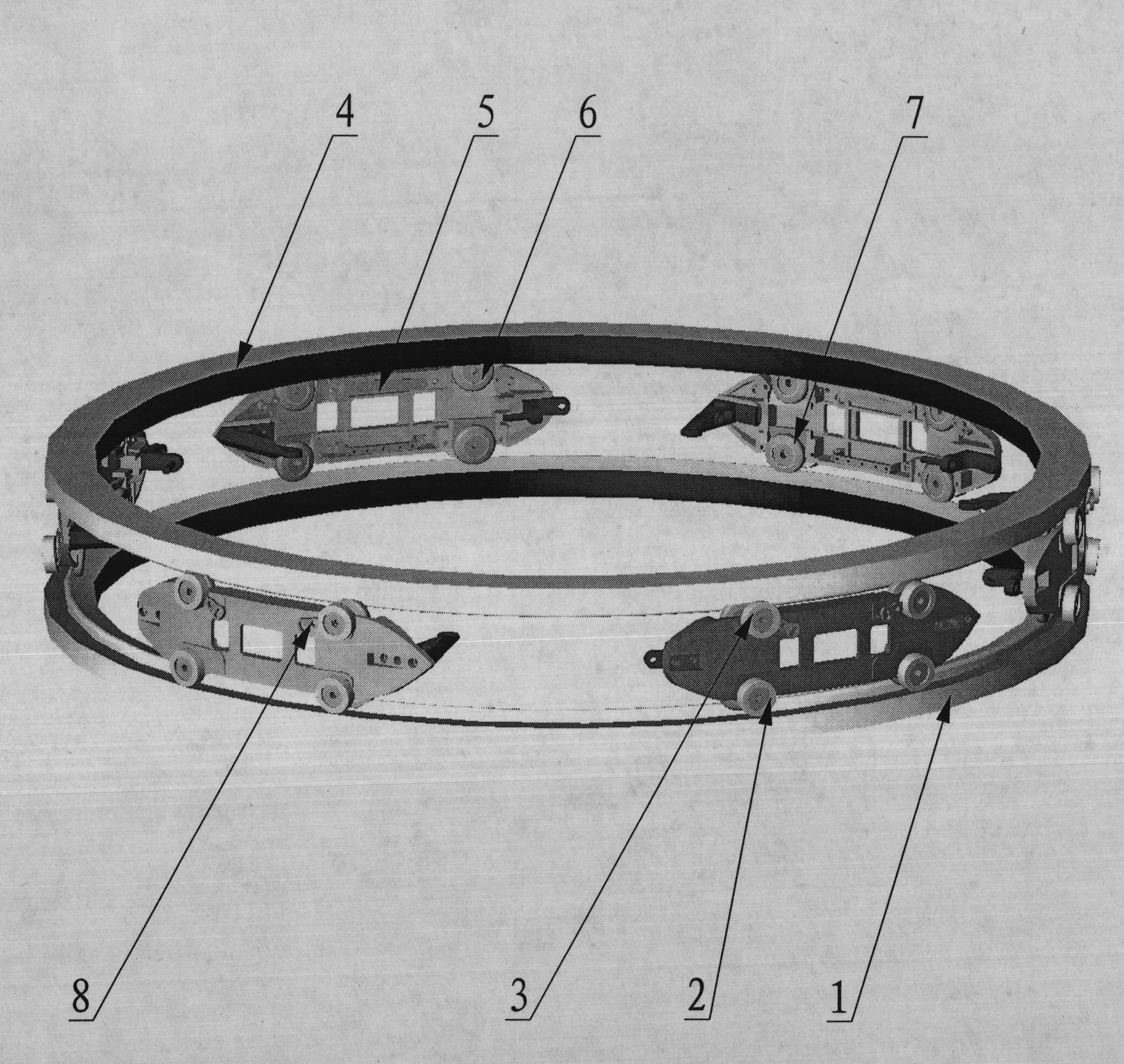

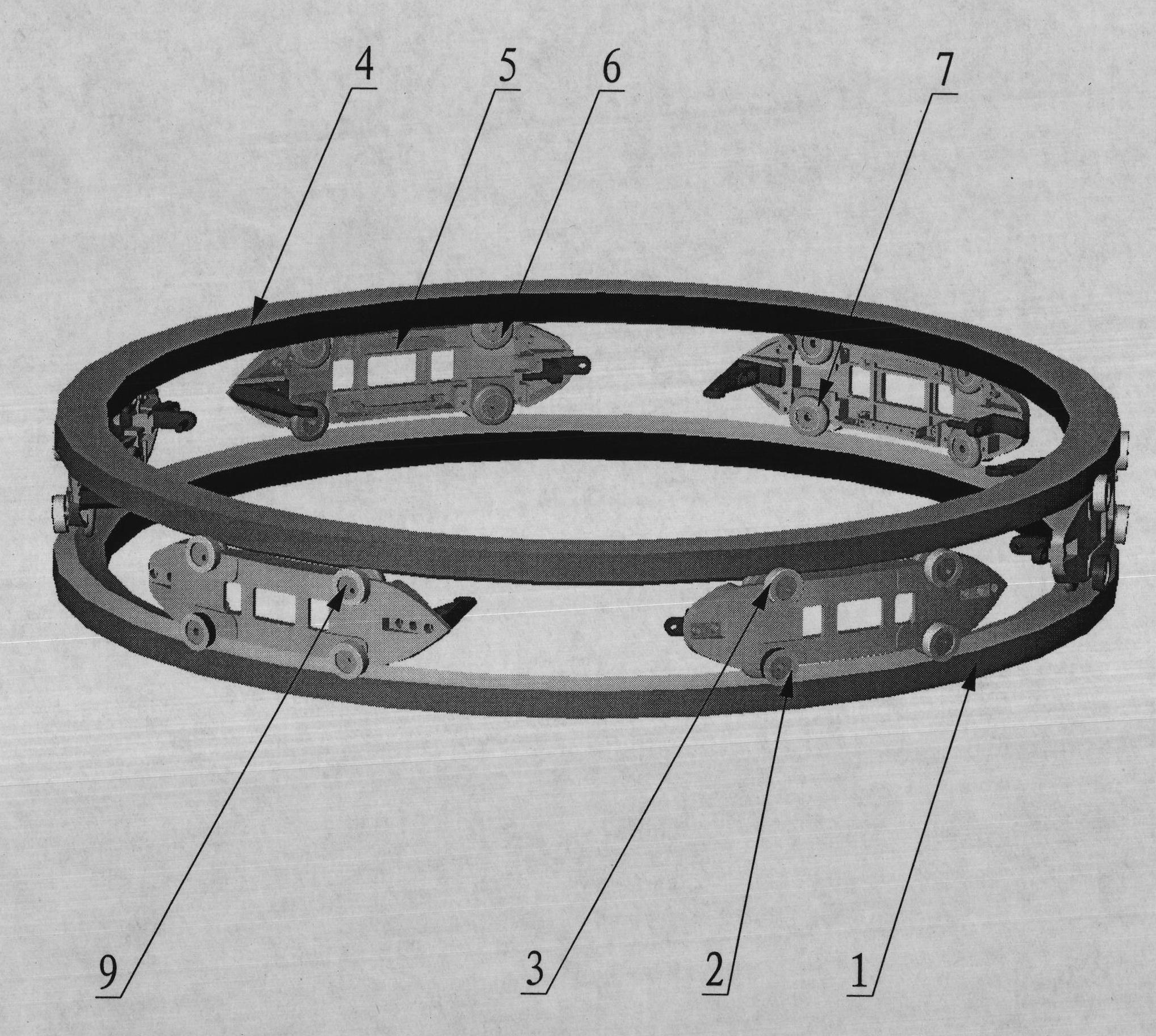

[0017] refer to figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the present invention, 1-lower door ring, 2-outside lower shuttle wheel, 3-outside upper shuttle wheel, 4-upper door ring, 5-shuttle hull, 6-inboard upper shuttle wheel, 7-Inside lower shuttle wheel, a shuttle boat and running track structure of a plastic circular loom, characterized in that the lower edge of the upper door ring 4 is designed as a double-cone surface, and the upper edge of the lower door ring 1 is designed as a double-cone surface , the inner cone surface of the upper door ring 4 and the inner cone surface of the lower door ring 1 form a set of shuttle wheel running tracks in the shape of an inner figure-of-eight, and the outer cone surface of the upper door ring 4 and the outer cone surface of the lower door ring 1 form an outer figure-of-eight shape. The running t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com