Emission current subdivision control circuit based on magnetic source electromagnetic method

A transmission current and segmental control technology, applied in the direction of irreversible DC power input conversion to AC power output, can solve the problem of increasing the electromagnetic interference intensity of the power conversion circuit, increasing the switching loss of the bridge switching device, and affecting the data acquisition of the receiver etc. to achieve the effects of reducing the influence of the primary field, reducing the current off time, and reducing the number of switching times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing when strength is described in further detail:

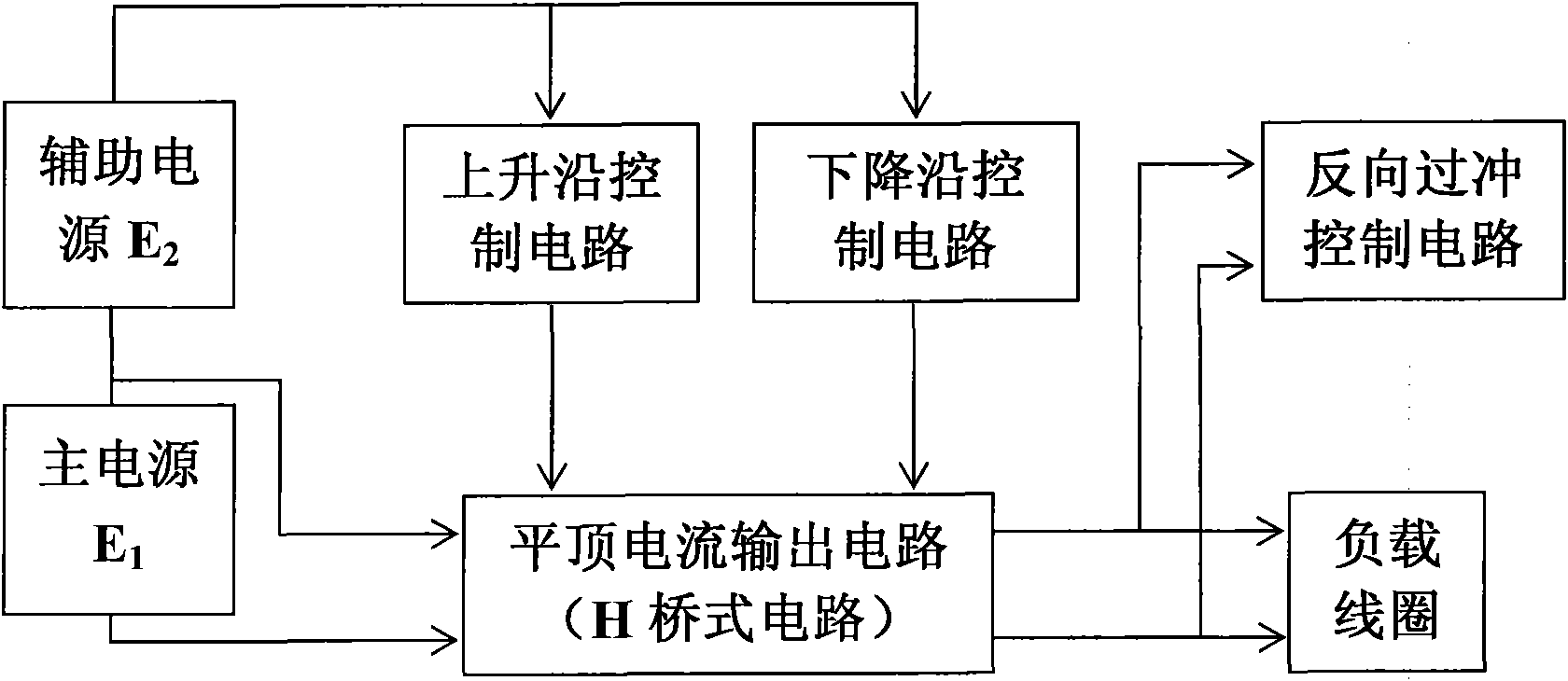

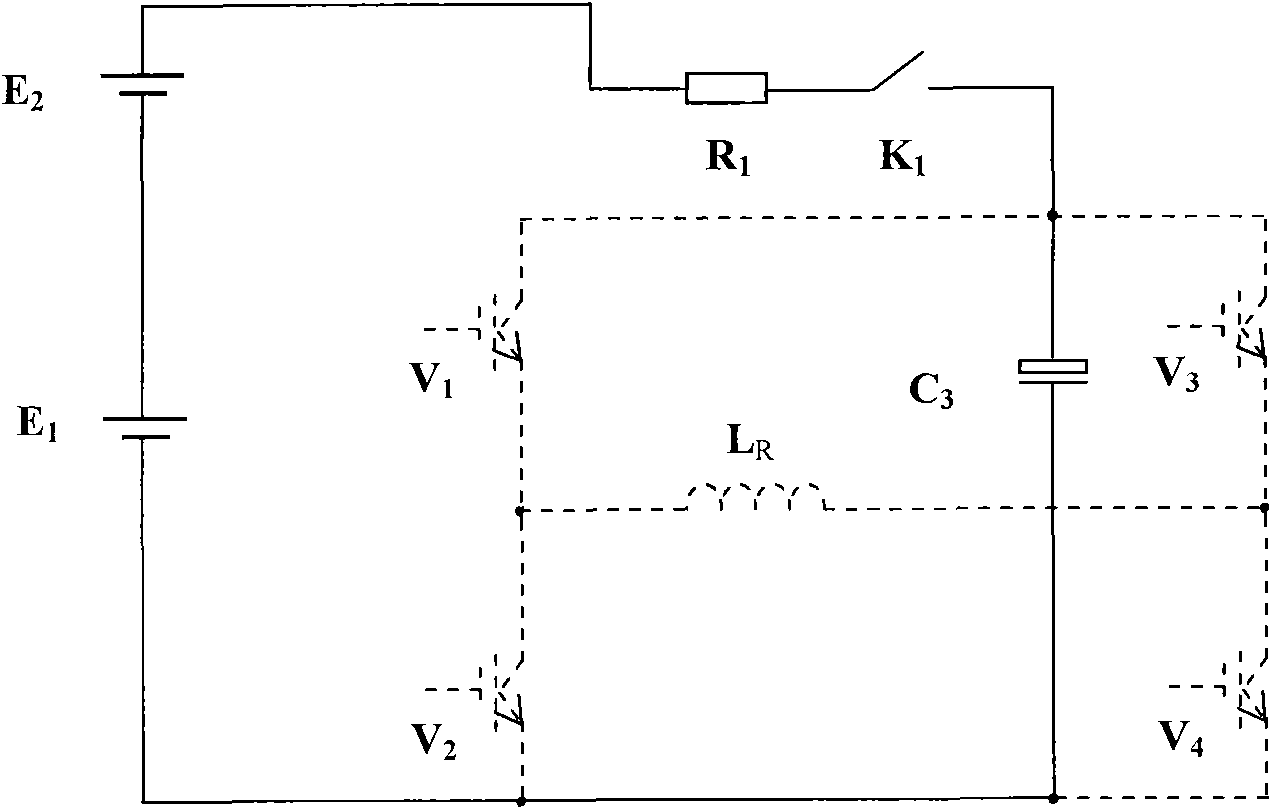

[0018] The circuit adopts four segments to precisely control the output current, and is controlled by the main power supply E 1 The load coil is connected in parallel with the reverse overshoot absorbing circuit through the H-bridge inverter main circuit, and the main power supply E 1 The positive terminal passes through the auxiliary power supply E 2 Finally, the rising edge control circuit and the falling edge control circuit are respectively connected in parallel to the H bridge inverter main circuit to form.

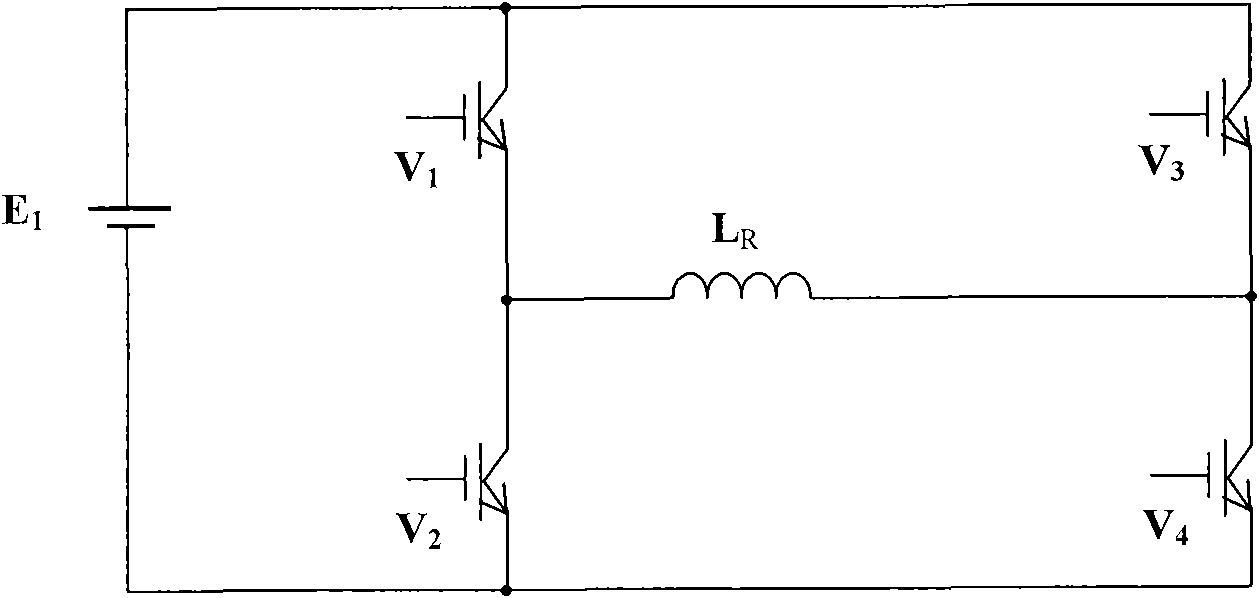

[0019] The H-bridge inverter circuit is composed of switching devices V 1 , V 2 , V 3 , V 4 and coil L R Composition, other parts are connected to the H-bridge inverter circuit.

[0020] The rising edge control circuit consists of two parts, the capacitor C 3 Directly connected in parallel to both ends of the power supply and ground of the bridge inverter cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com