Chained mode tensile supporting seat

A technology of tensile support and chain type, which is applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of restricted application range, unsatisfactory, limited ability to withstand tension, etc., to solve the problem of insufficient tensile capacity, compact structure, The effect of small flat space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structural features of the chain-type tensile support provided by the present invention and the working principle of realizing the tensile function and the process of realizing large horizontal displacement are described in detail below with reference to specific embodiments.

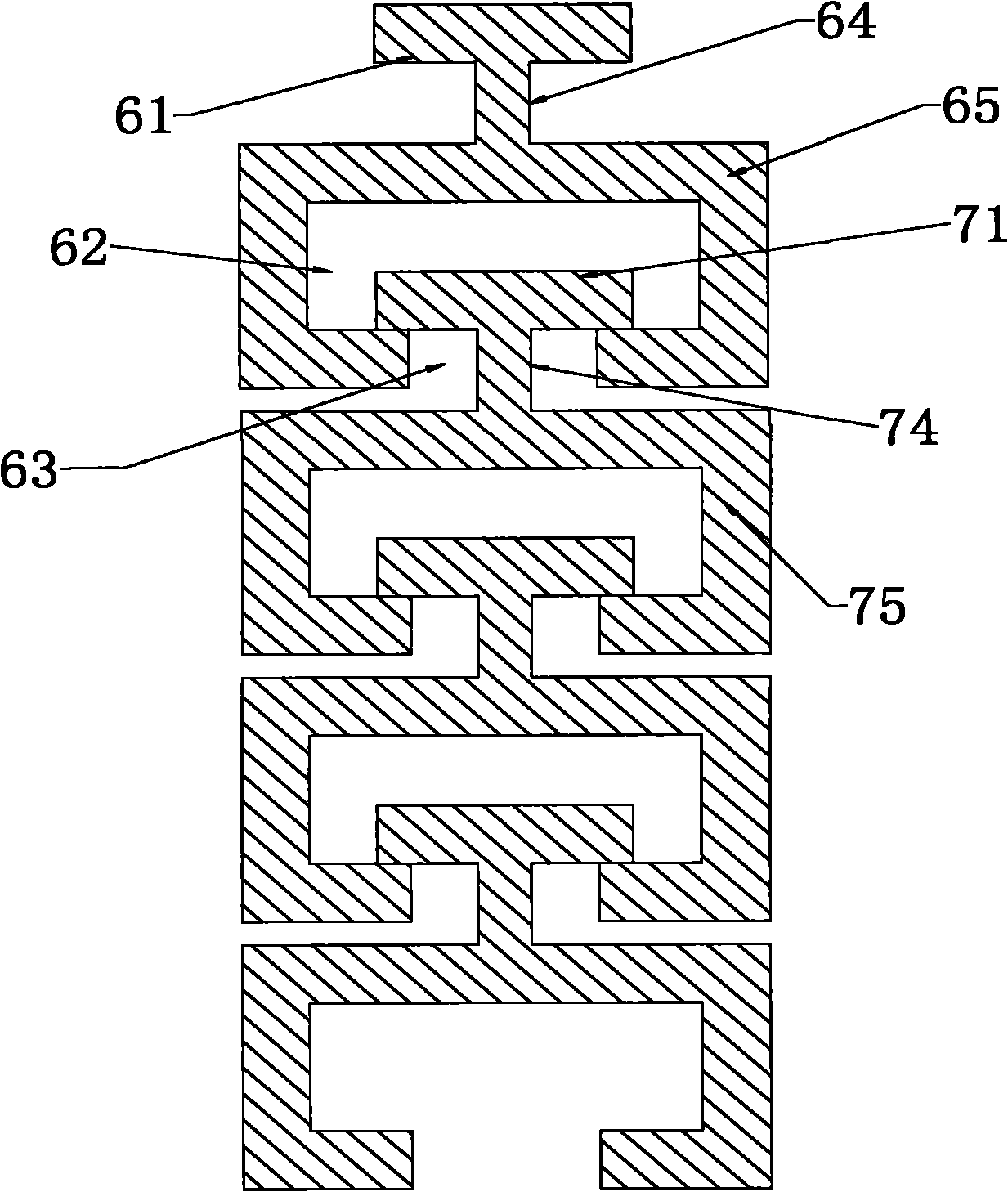

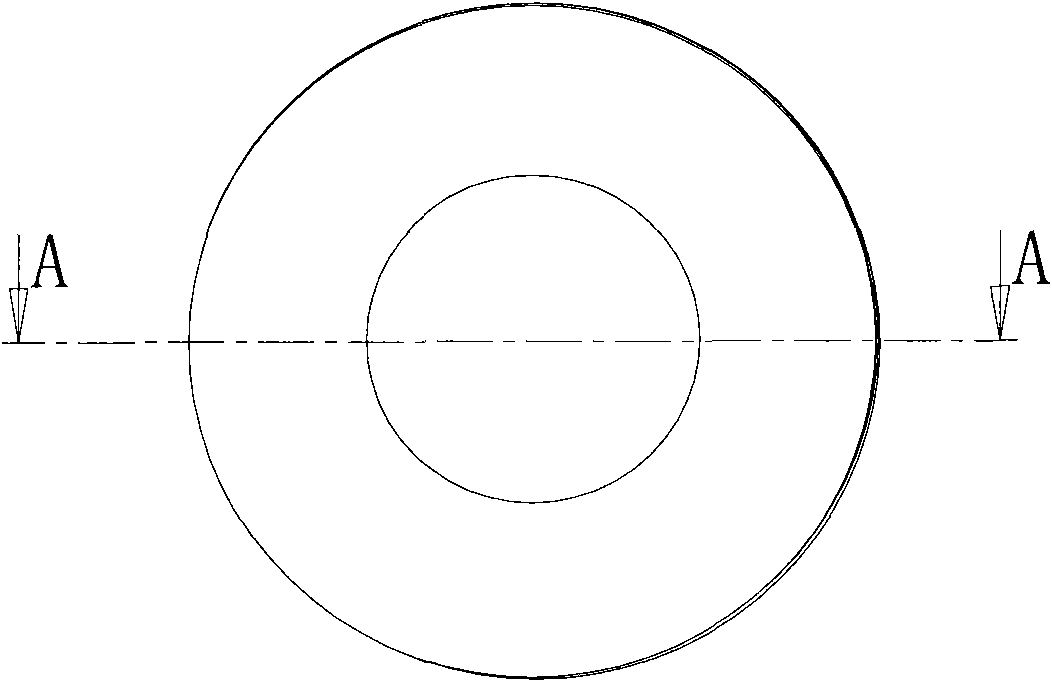

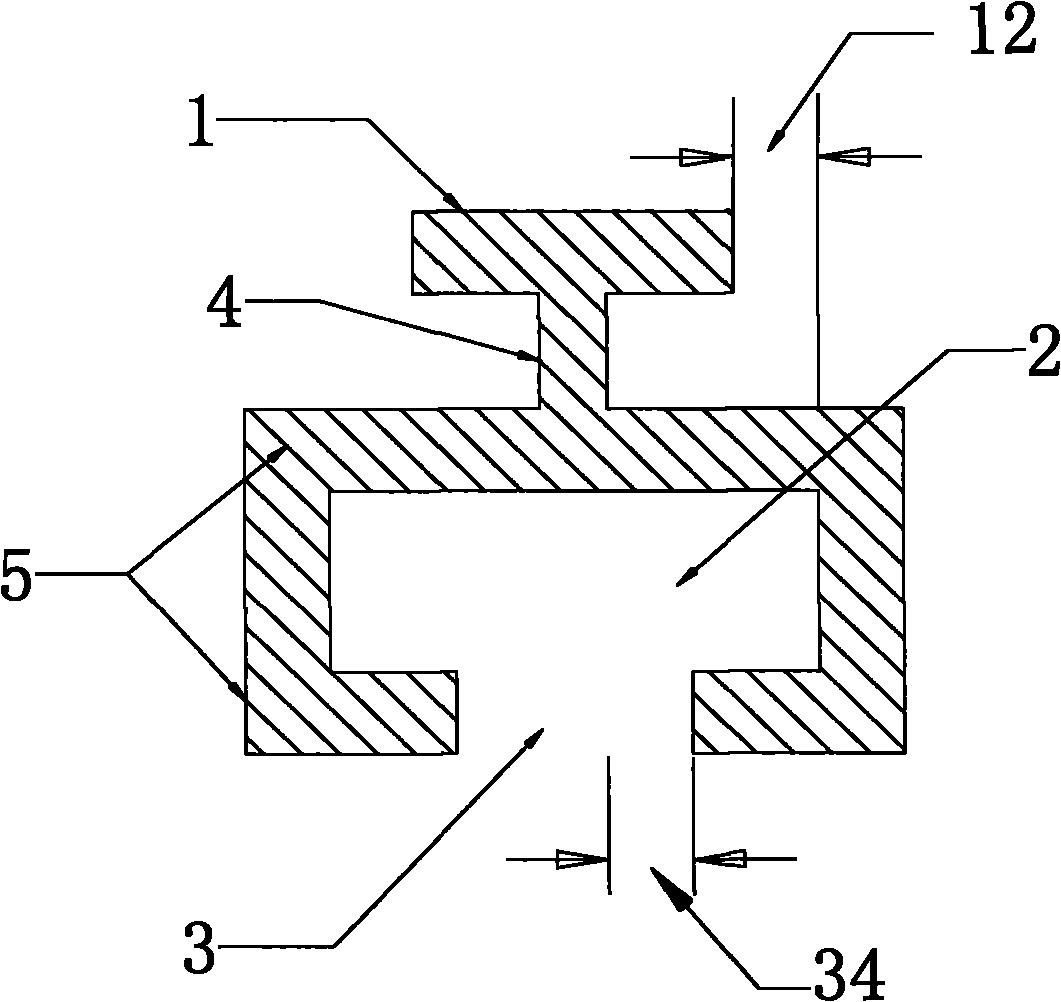

[0035] Figure 1 is a schematic top view of a chain tension support in an embodiment of the present invention when multiple chain units are stacked and sleeved, and Figure 2 is the AA direction of a single chain unit of the chain tension support shown in Figure 1 Cross-sectional view, FIG. 3 is a schematic front view of the four chain units in the chain-type tensile support of an embodiment of the present invention when they are stacked and sleeved, and FIG. 4 is a cross-sectional view taken along the line AA in FIG. 3. As shown in Figures 3 and 4, the chain-type tensile support disclosed in the present invention is characterized in that it comprises at least two chain units stacked one above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com