Duplex stainless steel wire material, steel wire, bolt, and method for production of the bolt

A technology for steel wire and bolts, which is applied in the field of duplex stainless steel wire and soft duplex stainless steel wire. It can solve the problems of difficult cold workability of wire rods, without considering the characteristics of softness and high tensile fracture shrinkage, and achieves excellent cold workability. , the effect of excellent cold forging

Active Publication Date: 2010-08-25

NIPPON STEEL STAINLESS STEEL CORP

View PDF16 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the examples, the steel containing 0.08% or more of nitrogen to improve the strength is described in order to improve the deep drawability of the steel sheet by improving the ductility. Cold workability is difficult

As mentioned above, among the conventional stainless steels, there is no stainless steel that has the softness and high fracture shrinkage characteristics necessary for the cold workability of wire rods, and is inexpensive and exhibits high corrosion resistance and magnetization.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

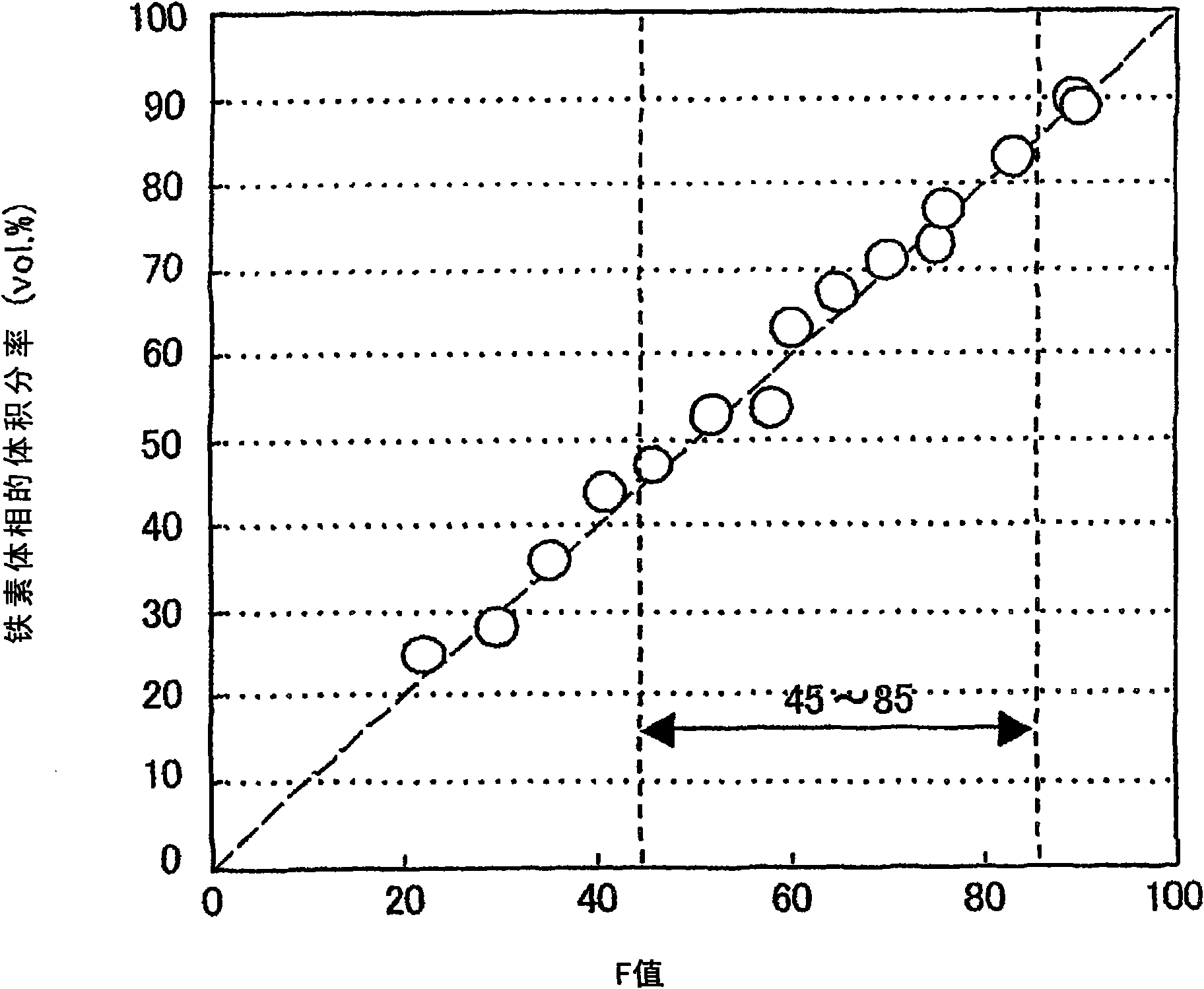

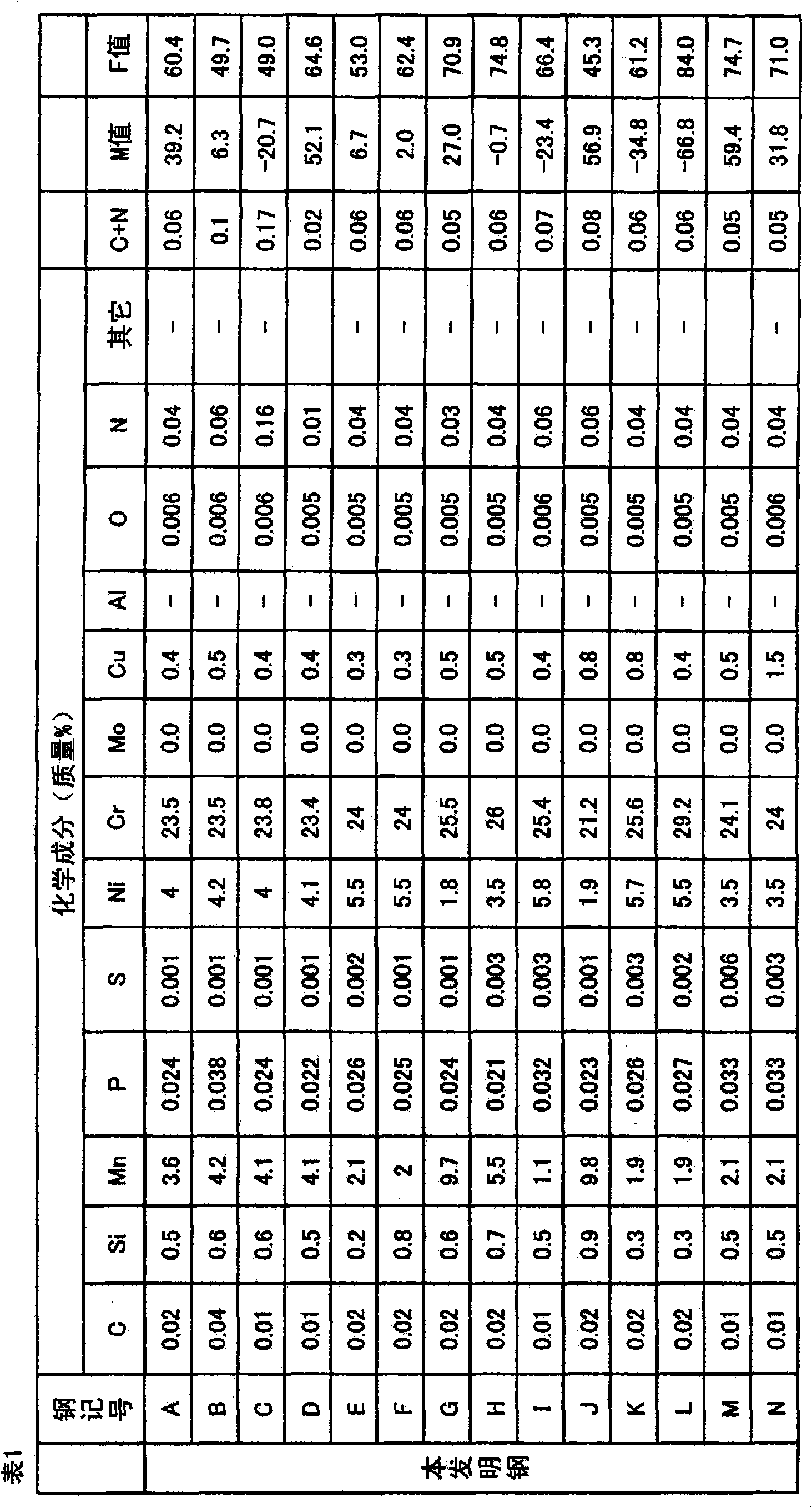

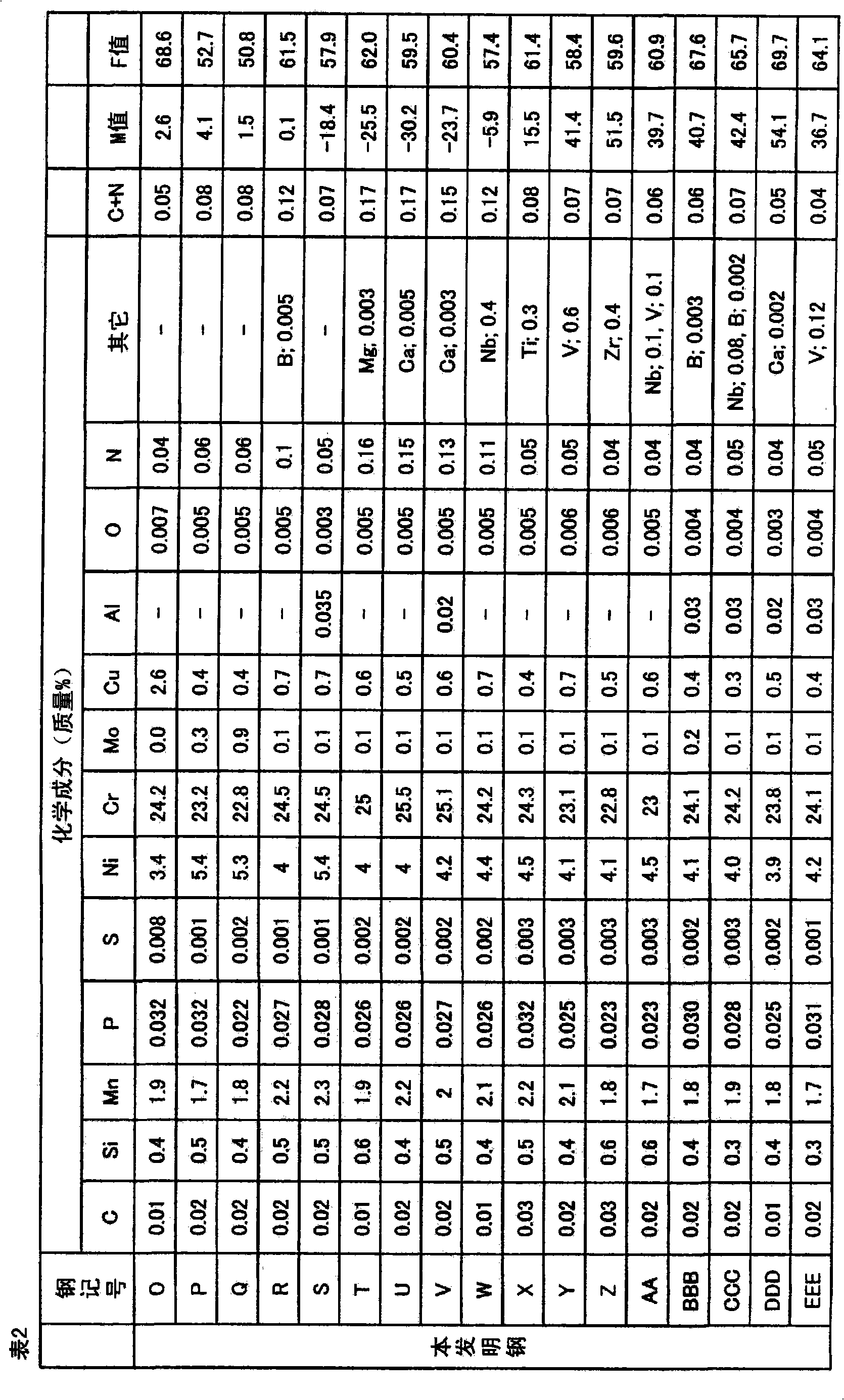

Disclosed is an austenite-ferrite duplex steel wire material for a high-strength, high-corrosion-resistant bolt, which has excellent cold forgeability. The steel wire material comprises the following components (by mass): C: 0.005-0.05%, Si: 0.1-1.0%, Mn: 0.1-10.0%, Ni: 1.0-6.0%, Cr: 19.0-30.0%, Cu: 0.05-3.0% and N: 0.005-0.20%, with the remainder being Fe and substantially unavoidable impurities, wherein the total content of C and N is 0.20% or less, the M value represented by the formula (a) below is 60 or less, the F value represented by the formula (b) is 45 to 85, and the tensile strength is 550 to 750 N / mm2. M = 551-462(C+N)-9.2Si-8.1Mn-29(Ni+Cu)-13.7Cr-18.5Mo (a) F = 5.6Cr-7.1Ni+2.4Mo+15Si-3.1Mn-300C-134N-26.6 (b).

Description

technical field The present invention relates to a duplex stainless steel wire rod excellent in cold forgeability, and provides, for example, a high-strength bolt having corrosion resistance equivalent to that of SUS304 at low cost. The present invention relates to a soft duplex stainless steel wire material with magnetizability and excellent cold workability, and more specifically to screws, pins, metal meshes, steel wires, steel cables, springs, etc., which can be provided at low cost and have corrosion resistance equivalent to, for example, SUS304 and SUS316 Soft duplex stainless steel wire material with strong cold workability and excellent cold workability with magnetization imparted at the same time. This application claims priority based on Japanese Patent Application No. 2007-264992 filed in Japan on October 10, 2007, and Japanese Patent Application No. 2007-264993 filed in Japan on October 10, 2007, the contents of which are incorporated herein by reference. Backgr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/00C21D6/00C21D9/00C22C38/58

CPCC21D6/02C22C38/42C22C38/002C22C38/02C21D2211/005C21D9/56C22C38/58C21D2211/001C22C38/44C22C38/001C21D8/06C21D6/004C21D7/02C21D8/065C21D9/0093C21D9/02C21D9/525

Inventor 高野光司柘植信二天藤雅之森祐司多田好宣

Owner NIPPON STEEL STAINLESS STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com