Collective doffing device of ring yarn spinning frame

A short-term, collective technology, applied in the direction of textiles and papermaking, can solve the problems of large spindle damage and damaged spindles, and achieve the effects of reducing labor, increasing automation, and achieving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

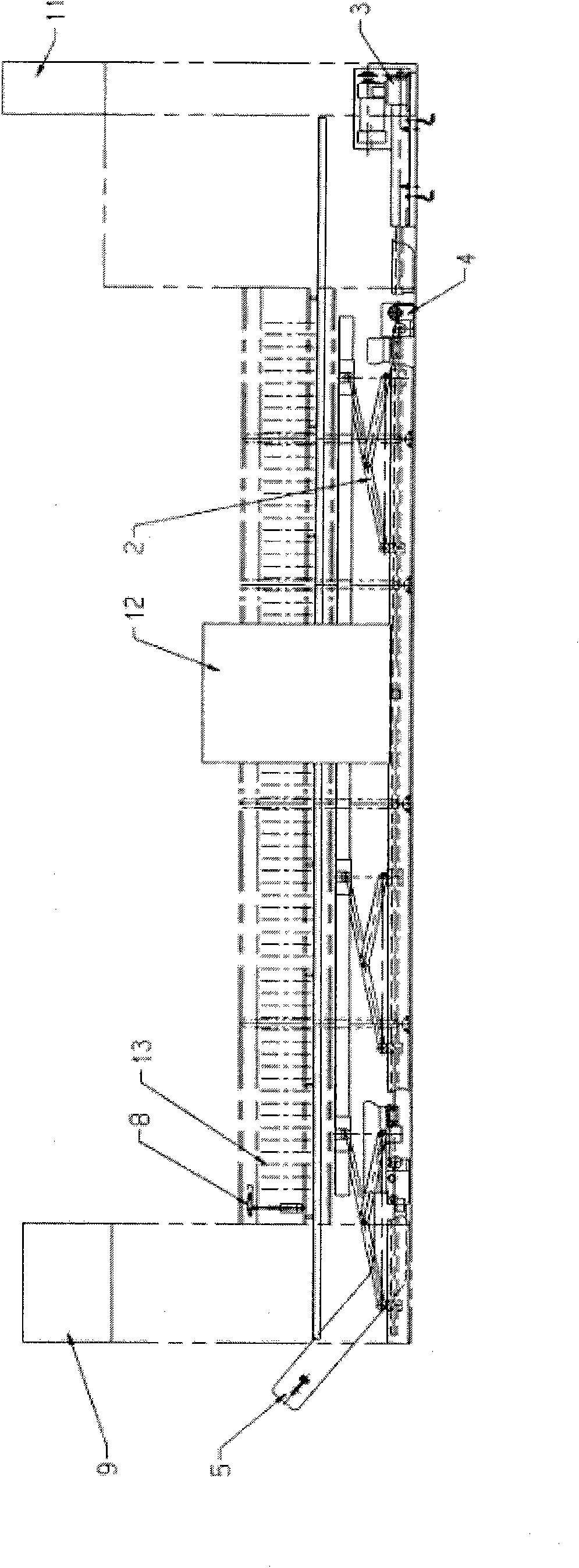

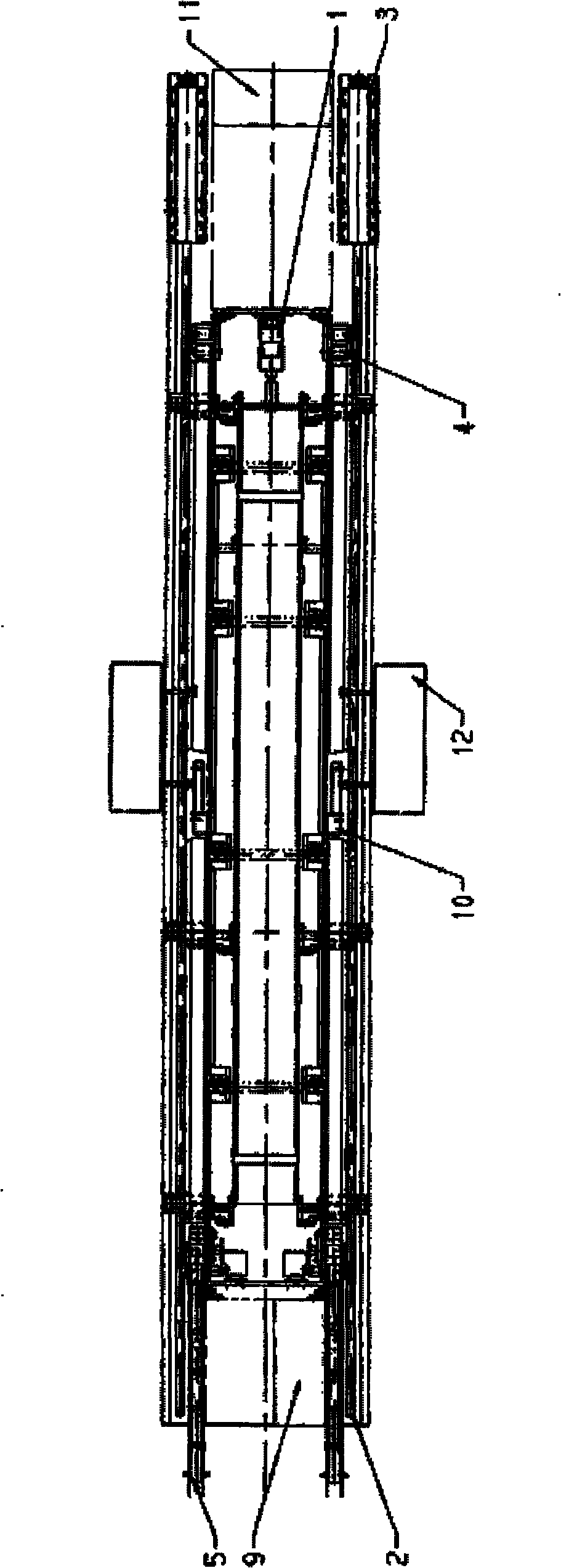

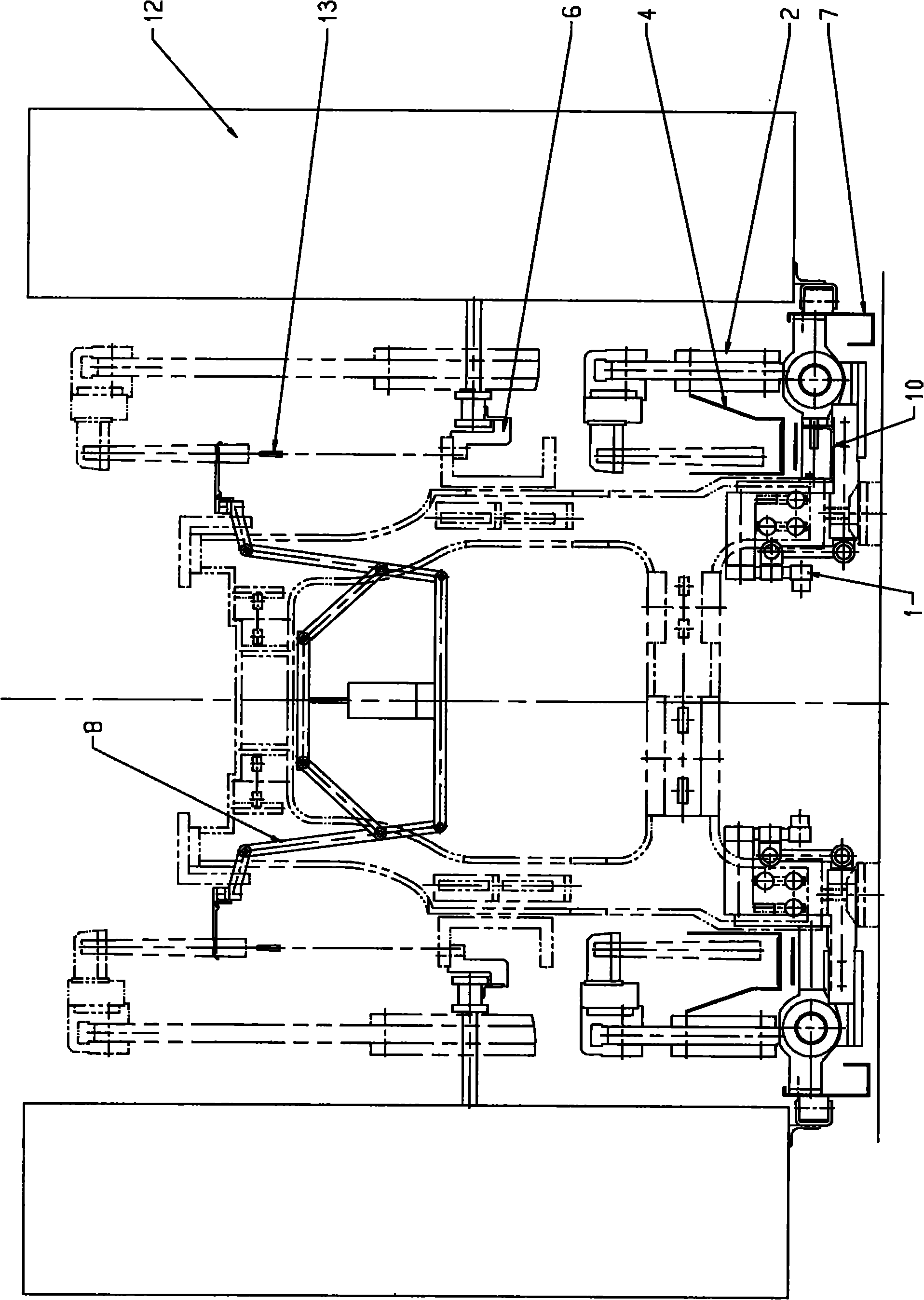

[0021] A collective doffing system for a short ring spinning machine, which includes an air frame swinging device 1, an air frame device 2, a screw drive device 3, a bobbin conveying device 4, a bobbin lifting device 5, and an upper guide rail device 6 , the lower guide rail device 7, the yarn guide plate turning device 8, the pneumatic control device 9, the air frame lifting signal device 10, the electrical control device 11, the intubation trolley 12 and the spindle 13, and the air frame inner and outer swing device 1 is arranged on the middle wall panel And on the bottom of the head and tail, the inside and outside swing device 1 of the air frame is in the form of a double push-pull rod powered by a cylinder, which makes the air frame device 2 swing inside and out; as Figure 4 As shown, the inside and outside swing device 1 of the air frame includes a cylinder 14, a cylinder joint 15, a first connecting rod 16, a transmission connecting rod 17, a pin shaft 18, a swing arm 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap