Box girder transfer platform and girder transferring and girder loading working procedures thereof

A platform and box girder technology is applied in the field of box girder transfer platform and its beam shifting and girder installation procedures, which can solve the problems of inability to adapt to the loading and unloading of beams of different specifications, complicated beam installation procedures, etc., and achieves high construction efficiency and good environmental performance. , the effect of low platform cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

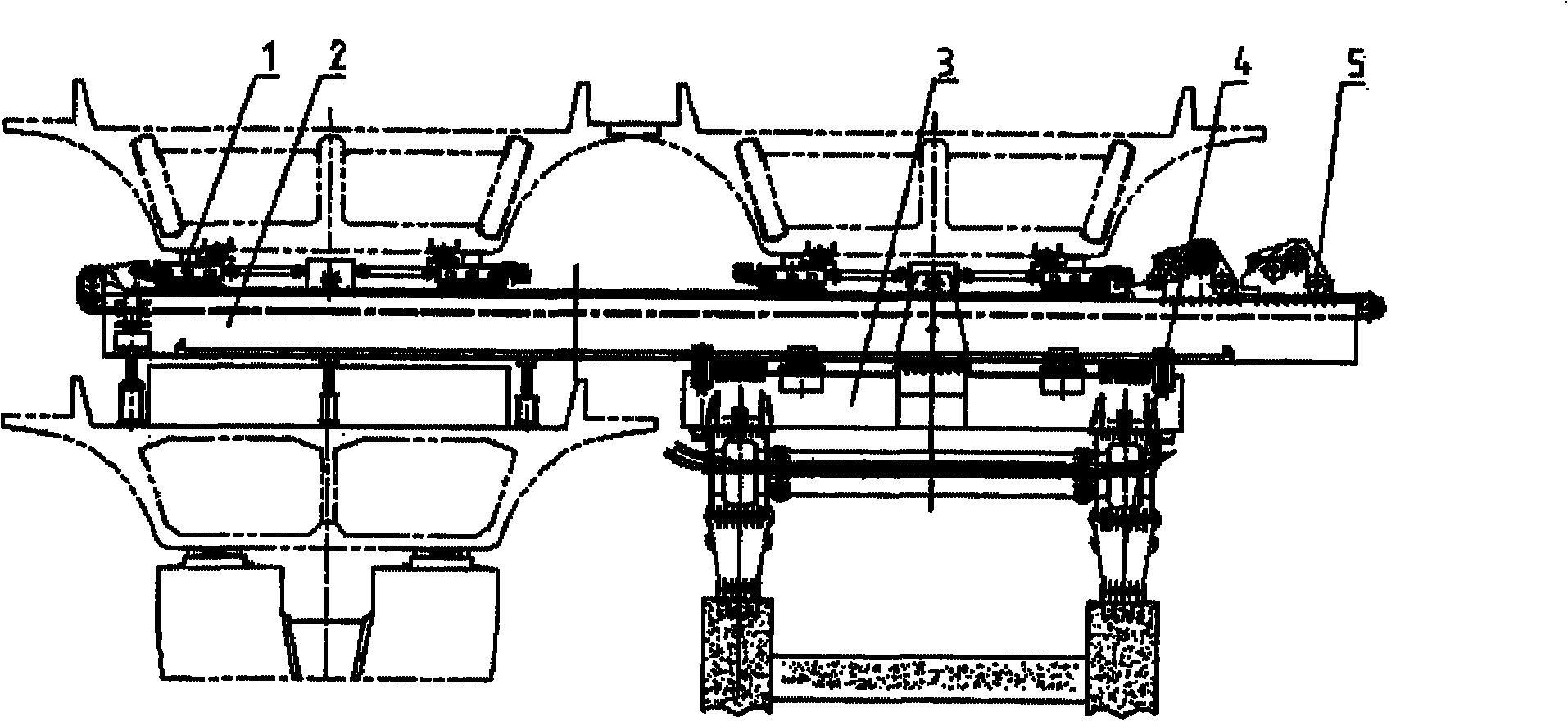

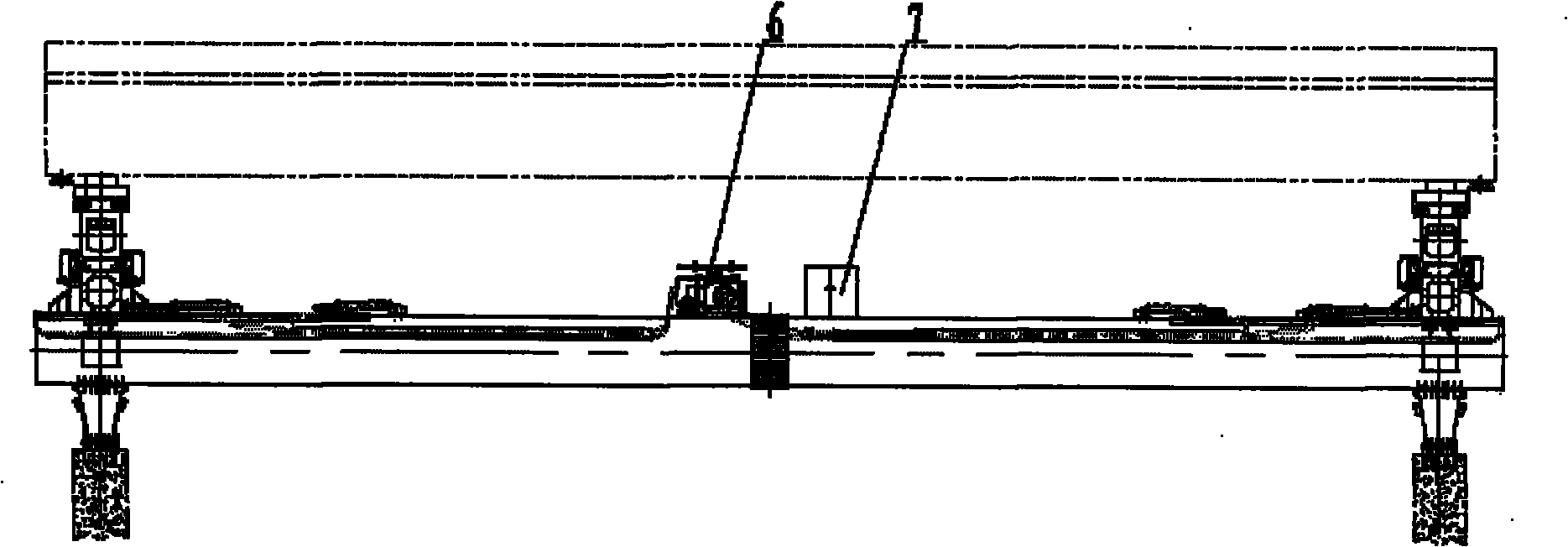

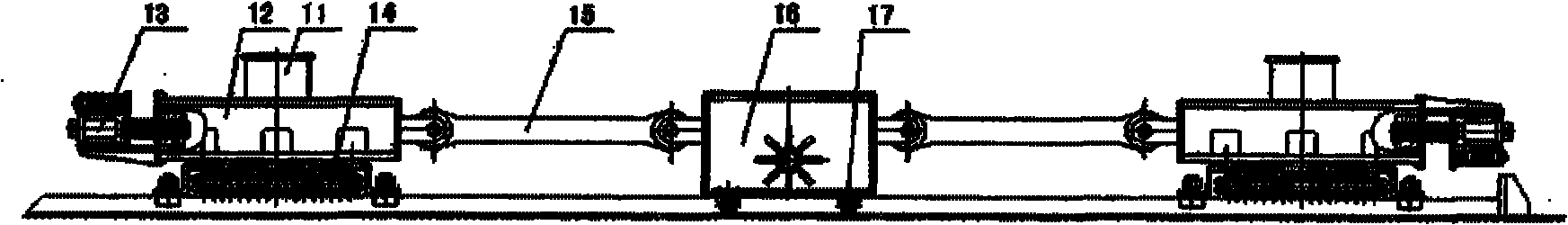

[0063] Referring to Fig. 1, it is a box girder transfer platform of the present invention, which is mainly composed of a beam trolley 1, a telescopic arm 2, a beam assembly 3, a portal frame 4, a drive system 5, a hydraulic system 6, and an electrical system 7. Among them, the hydraulic system 6 can be composed of a pumping station and related actuators. When used to complete the beam moving requirements of box girders with different spans, the pumping station and actuators that meet the requirements can be selected according to the needs; and the electrical system 7 can be controlled by a frequency converter. , control box, electrical cabinet, etc., mainly realize overcurrent, overvoltage, undervoltage, leakage and other protections and centralized control of all actions (such as linkage, emergency stop, etc.), since the hydraulic system 6 and electrical system 7 are both well known techniques and therefore will not be described in detail. The beam trolley 1 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com