Large-section tunnel advanced large pipe shed multi-operation-surface construction method

A technology of an advanced large pipe shed and a construction method is applied in the field of tunnel advanced support structure construction, which can solve problems such as mutual interference and low construction efficiency, and achieve the effect of reducing mutual influence and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Attached below image 3 And embodiment to further illustrate the technical scheme of the present technology invention.

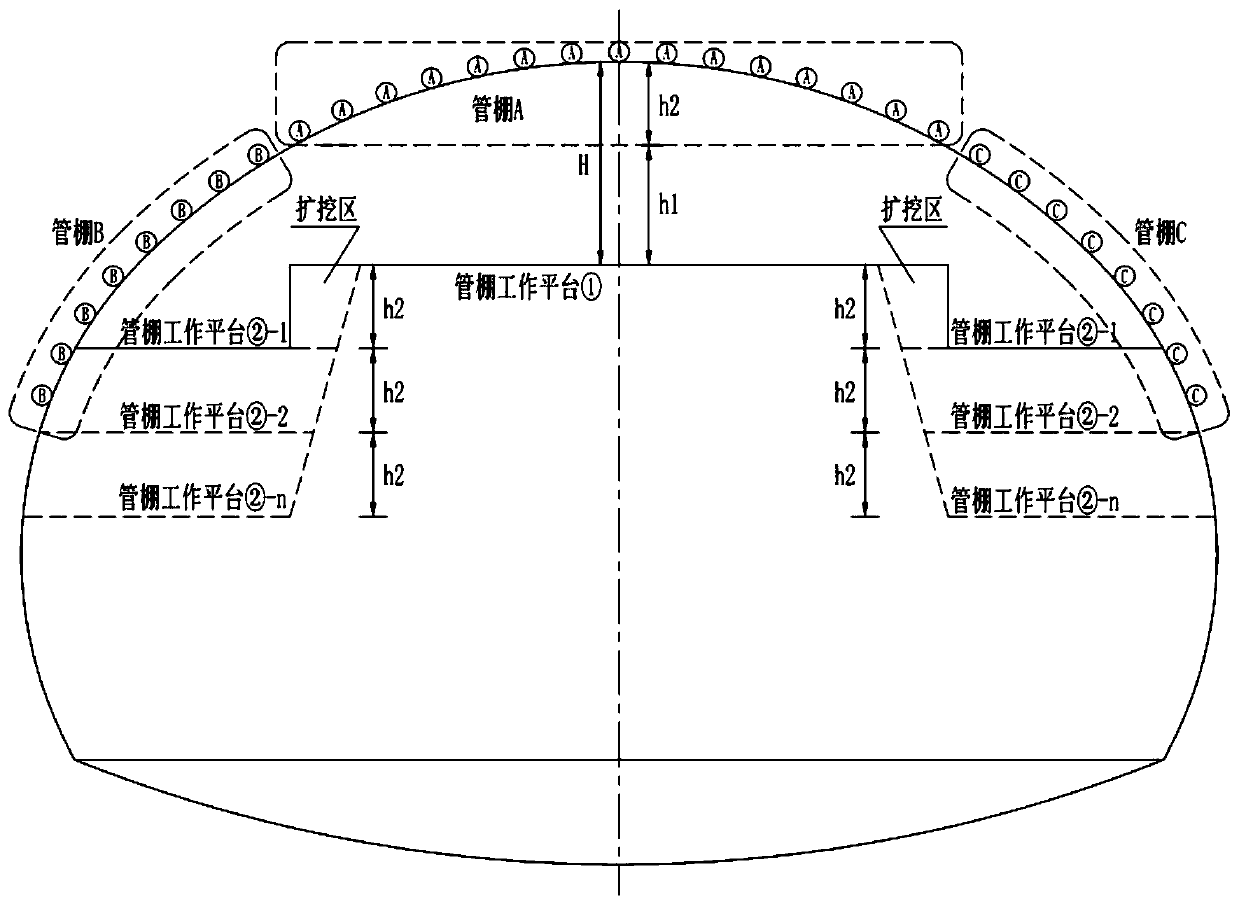

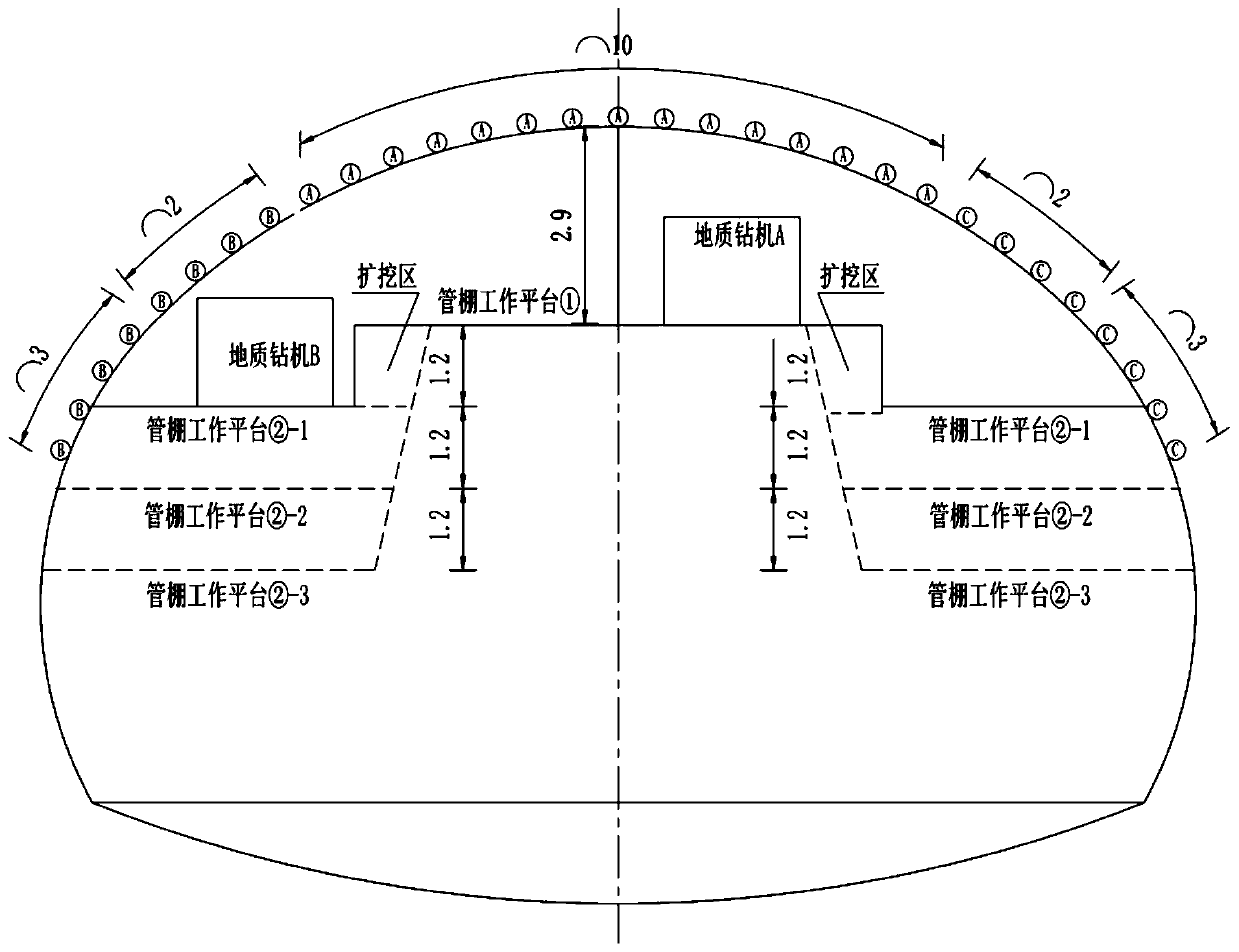

[0020] The embodiment is a three-lane three-center circle tunnel. The outer contour span of the tunnel structure is about 17.0m. The pipe shed is arranged according to the 120° range of the arch. The implementation steps of the technical solution include:

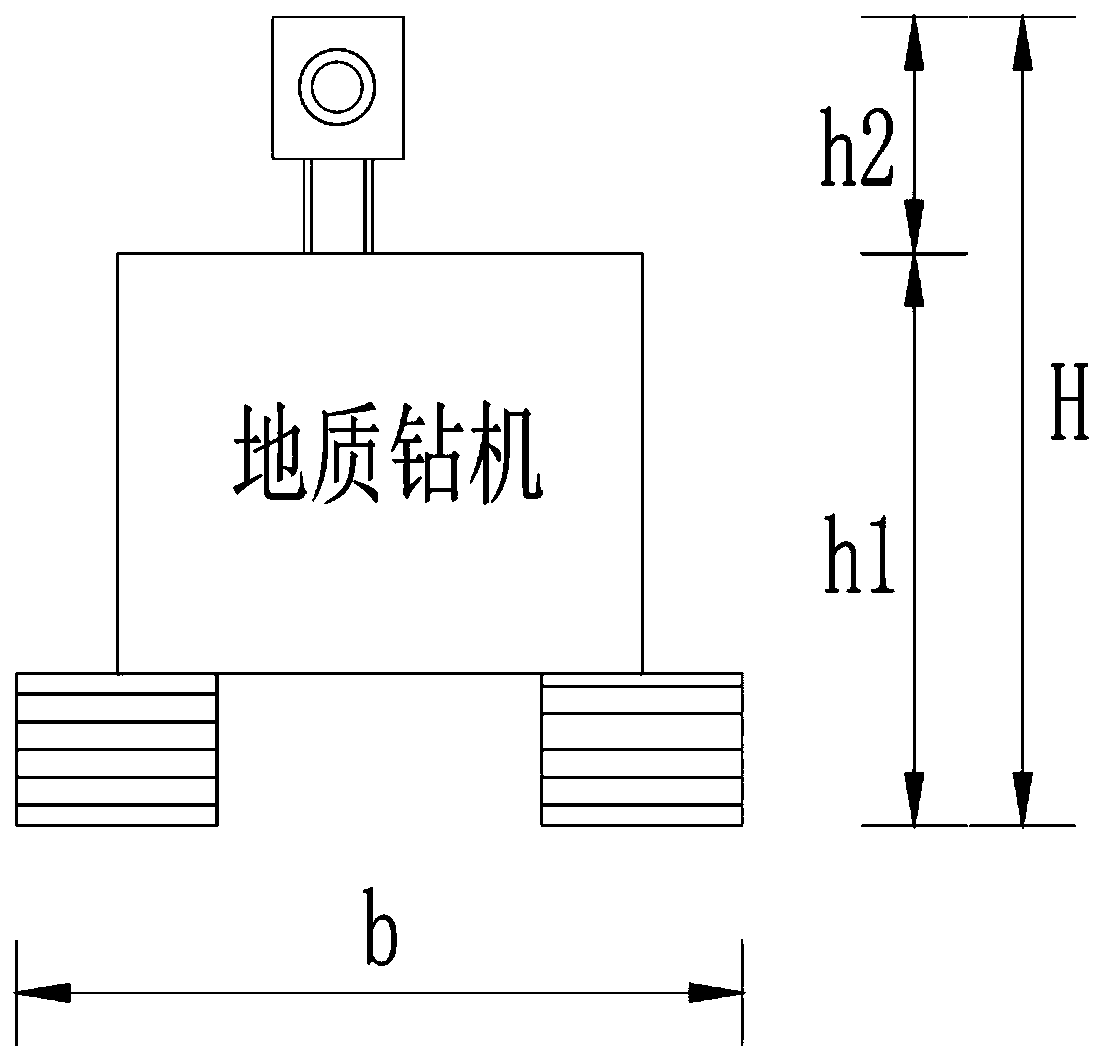

[0021] 1. Measuring equipment working space: HC726 down-the-hole drilling rig is used. The horizontal width of the drilling rig is 2.4m. The minimum and maximum heights of horizontal drilling are 1.7m and 2.9m respectively, and the adjustable height is 1.2m.

[0022] 2. Division of the pipe shed working area: Mark the pipe shed hole within 1.2m of the highest point of the pipe shed hole as the pipe shed area A, calculate the arc length of the pipe shed in the pipe shed area A to be about 10m, and the rest are located in the tunnel The total arc length of pipe shed areas B and C on both sides is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com