Test method for measuring bond stress between reinforcing steel bars and concrete

A technology of bonding stress and test method, which is applied in the field of mechanical testing, can solve the problems of distortion of test results, large damage to steel bars, and high scrap rate, and achieve the effects of convenient waterproof and moisture-proof treatment, simple test method, and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

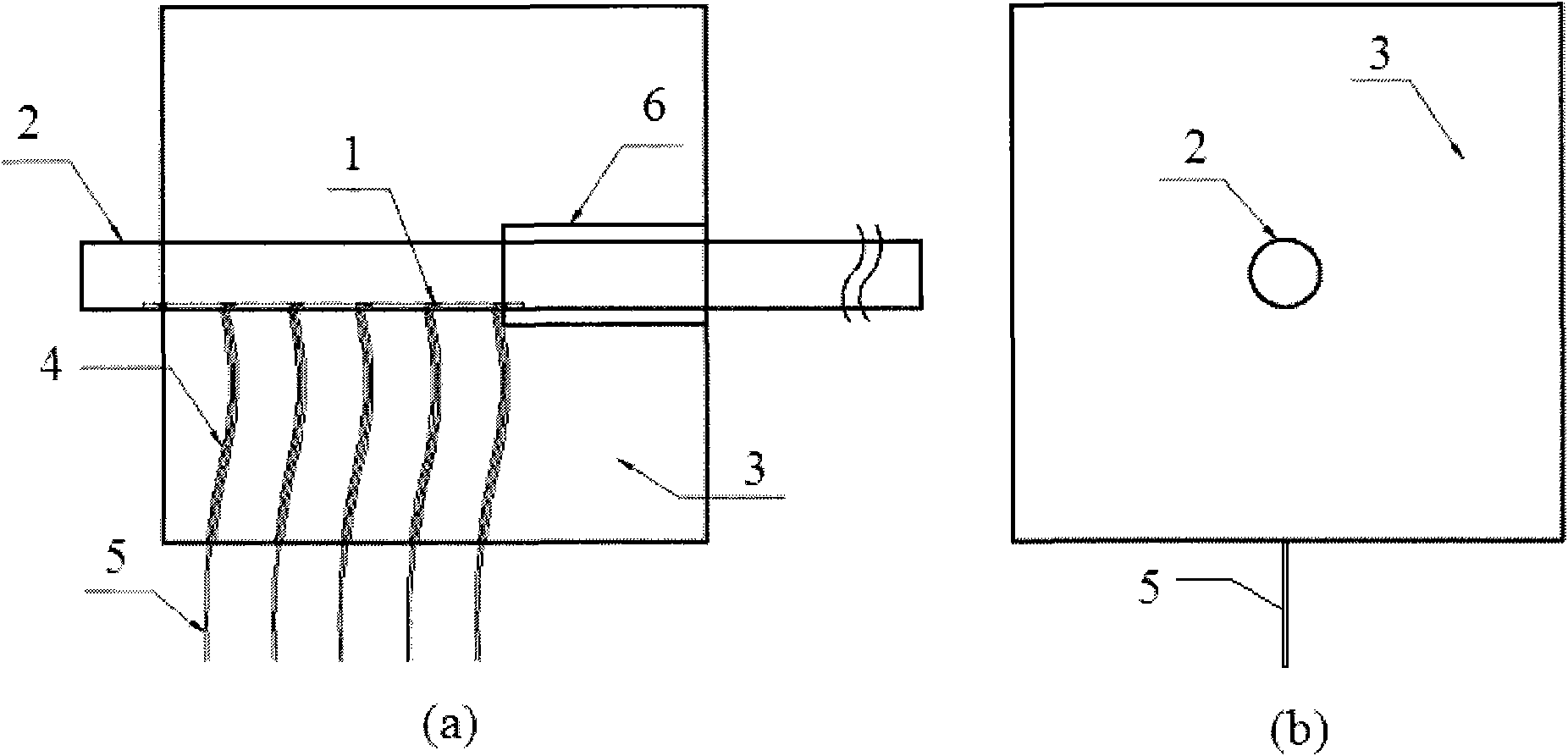

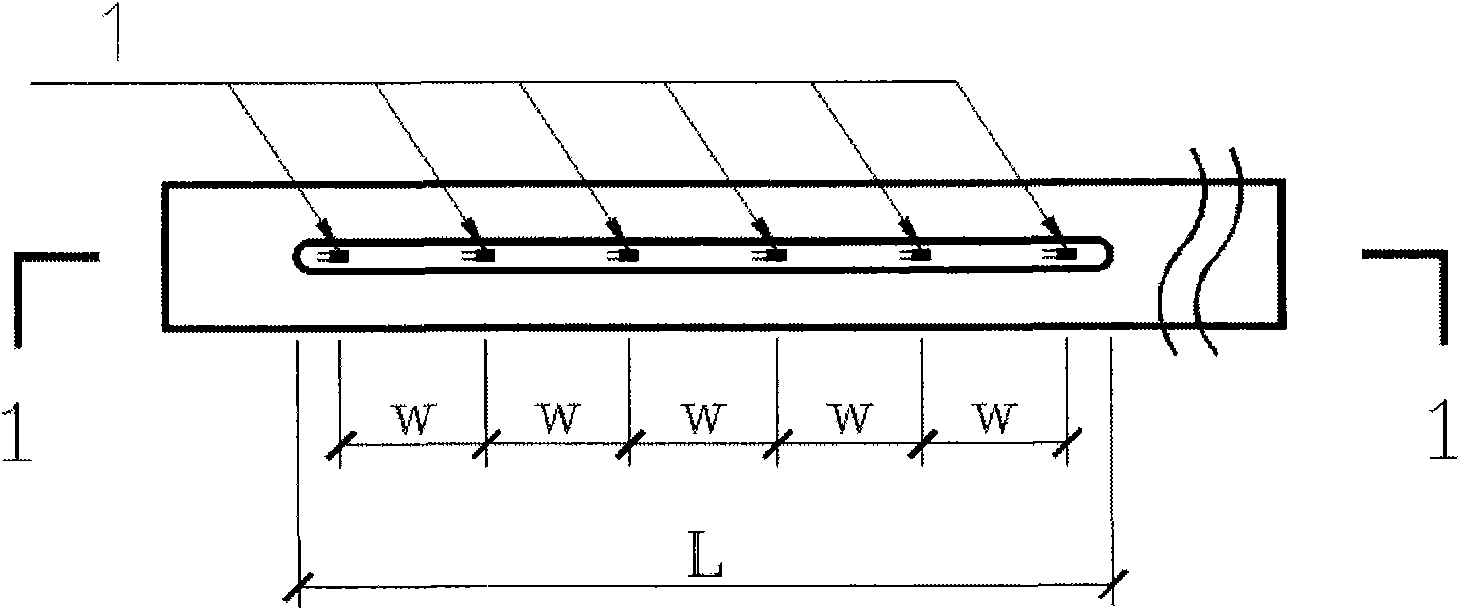

[0029] The specimens prepared according to this test method are as follows: figure 1 shown. The concrete test block 3 contains a foil strain gauge 1 , a slotted steel bar 2 , a plastic flexible conduit 4 , a strain gauge wire 5 , and a plastic flexible sleeve 6 . The most important part is the pasting and preparation of slotted steel bars 2 and foil strain gauges 1, such as Figure 3-5 shown. The technical requirements in the preparation process are detailed below:

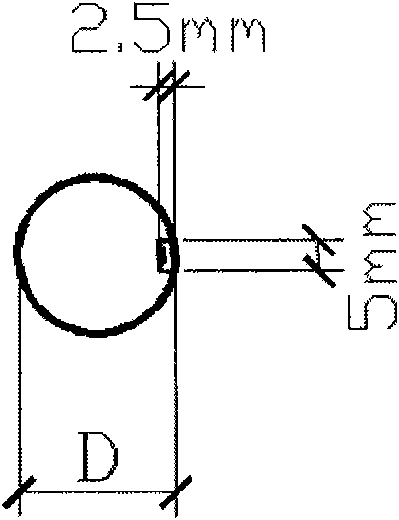

[0030] (1) Rebar slotting: see Figure 2 ~ Figure 4 The steel bars are grooved longitudinally along the surface by a milling machine to ensure accuracy. The groove depth is 2.5mm and the groove width is 5mm. ). For light round steel bars and deformed steel bars with regular circumference, grooves can be made at any position, and for crescent rib steel bars, grooves should be made on the longitudinal ribs to reduce damage to the surface of the steel bars;

[0031] (2) Foil-attached strain gauges: Foil-type st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com