Motor rotor conducting bar punching machine

A technology of motor rotors and guide bars, applied in the field of impact devices, can solve problems such as low production efficiency and unstable quality, and achieve the effects of improving work efficiency, stabilizing product quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

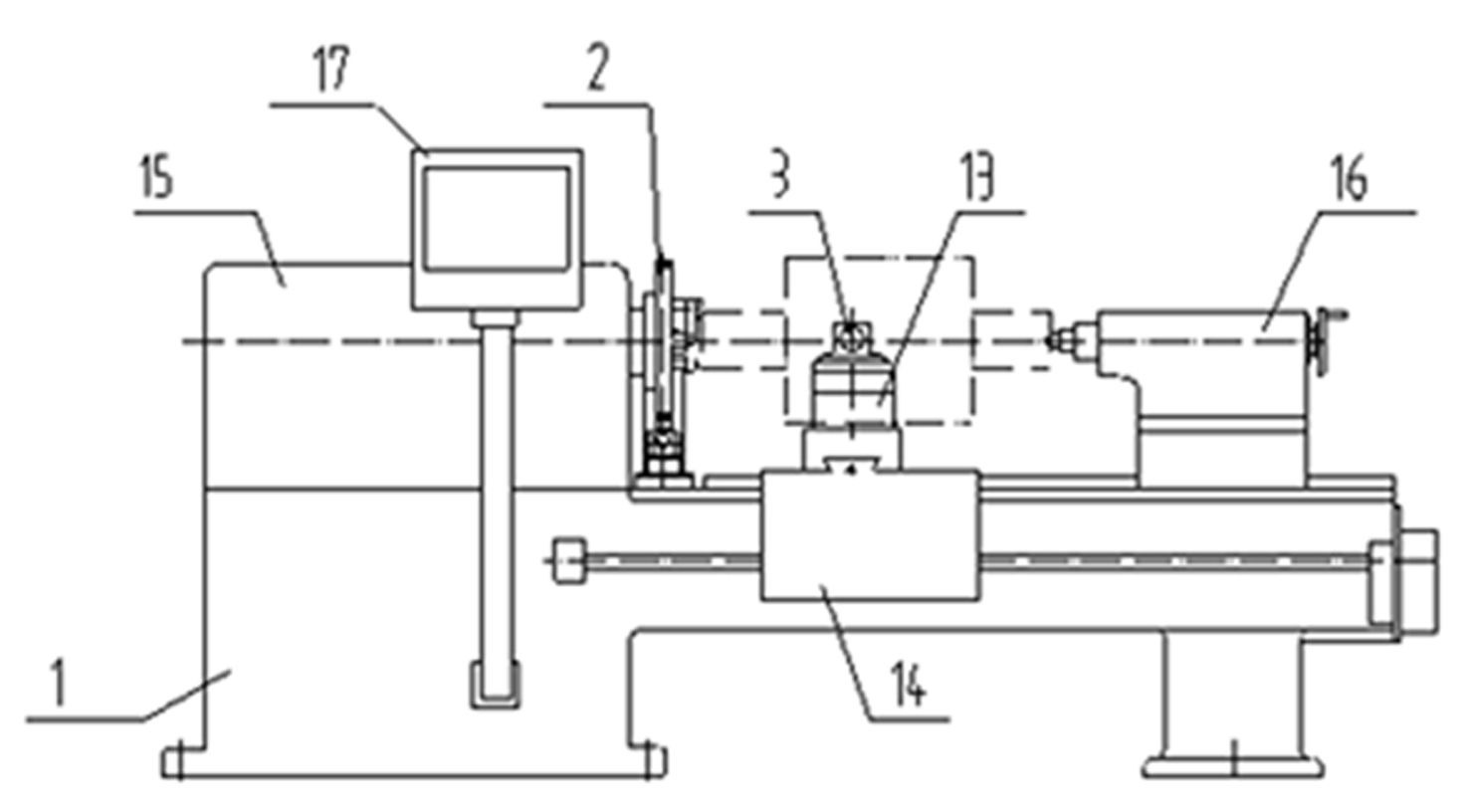

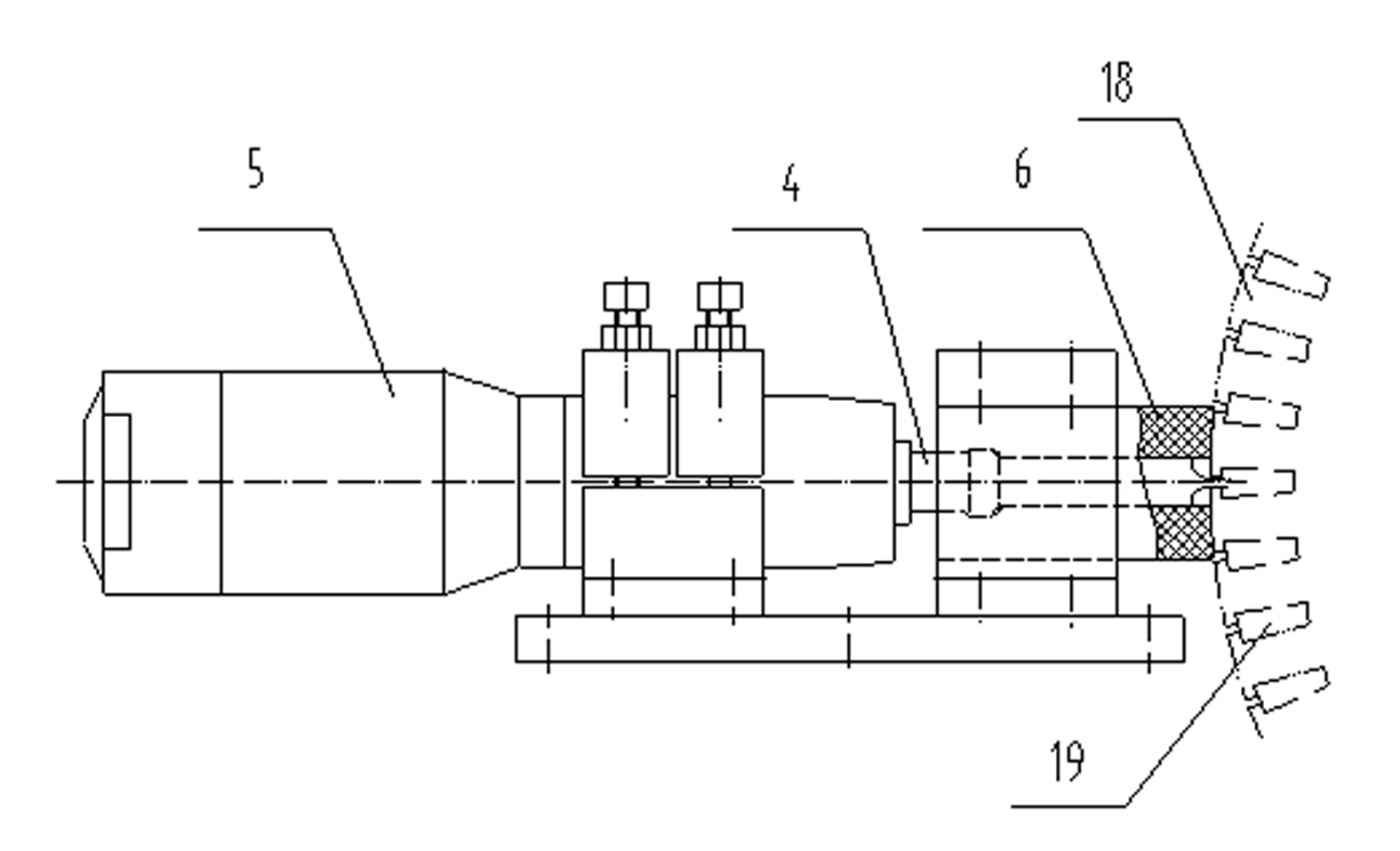

[0011] A motor rotor guide bar flushing machine according to the present invention, such as figure 1 As shown, it includes a clamping mechanism fixed on the machine body 1, a feed mechanism controlled by a control unit, and an intermittent indexing positioning device 2. The feed mechanism is fixed with an impact device 3 controlled by a control unit. The device 3 comprises a percussion cylinder 5 to which a punch 4 is connected, controlled by a control unit. The control unit is contained in the control box 17.

[0012] The impact device 3 also includes a guide block 6 arranged in front of the punch 4 to cooperate with the punch 4 . The guide block 6 has the functions of limiting the angular displacement of the punch, buffering and controlling the depth of the deformation groove. Guide block 6 can be made of elastic material.

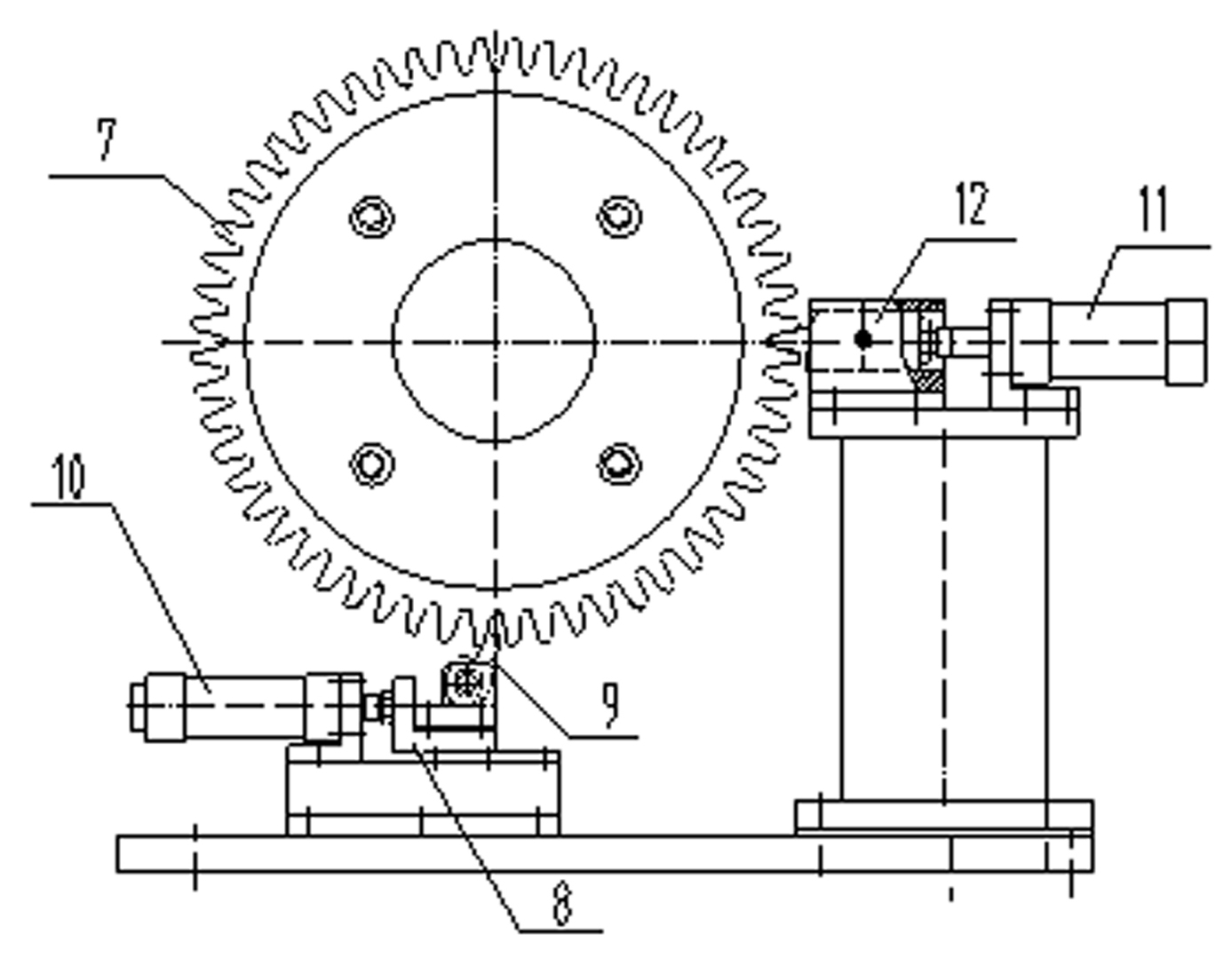

[0013] As shown in Figure 3, the intermittent indexing positioning device 2 includes a ratchet mechanism and a positioning device. The ratchet mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com