System and method for automatically testing power of display equipment on production line

An automatic test system and display equipment technology, applied in the direction of measuring electric power, electric vehicles, measuring devices, etc., can solve problems such as waste of labor, low production efficiency, and long production waiting time, so as to save labor, improve production efficiency, and change human resources. The effect of working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

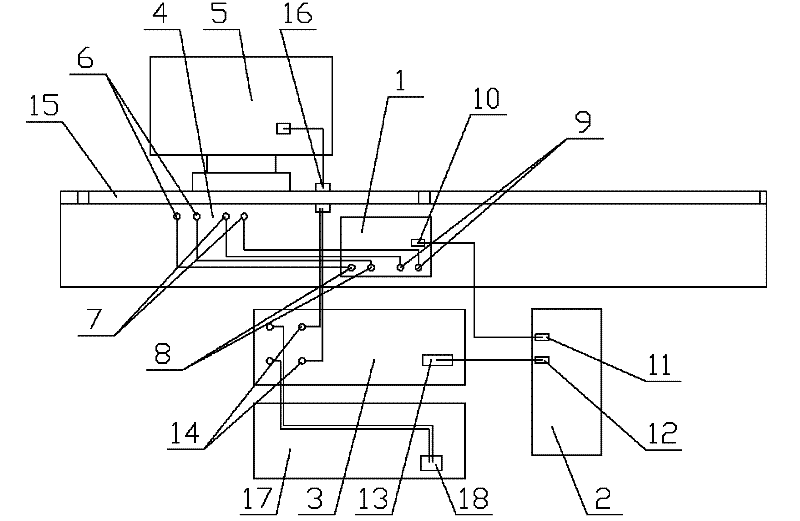

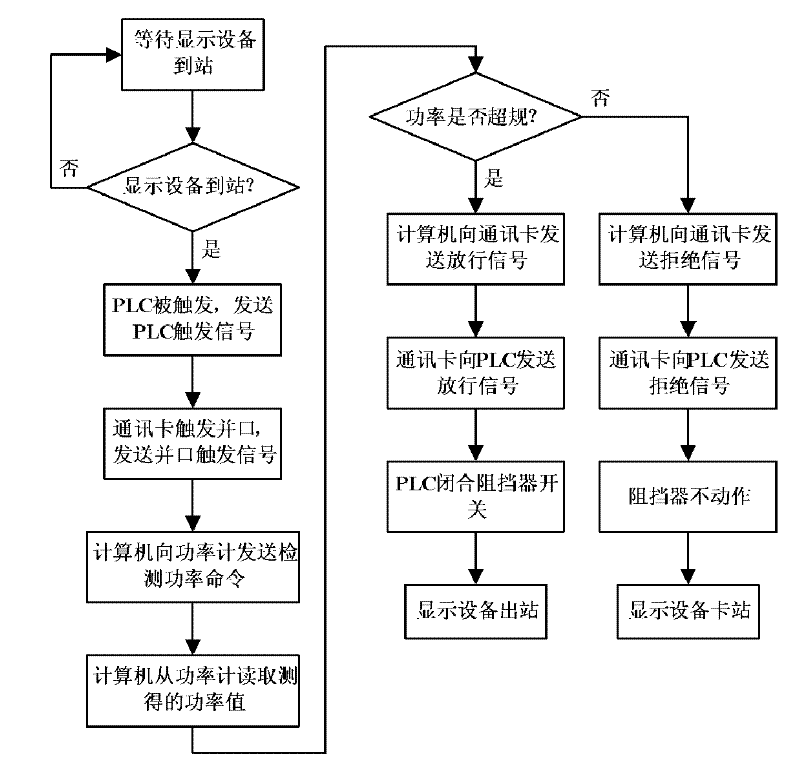

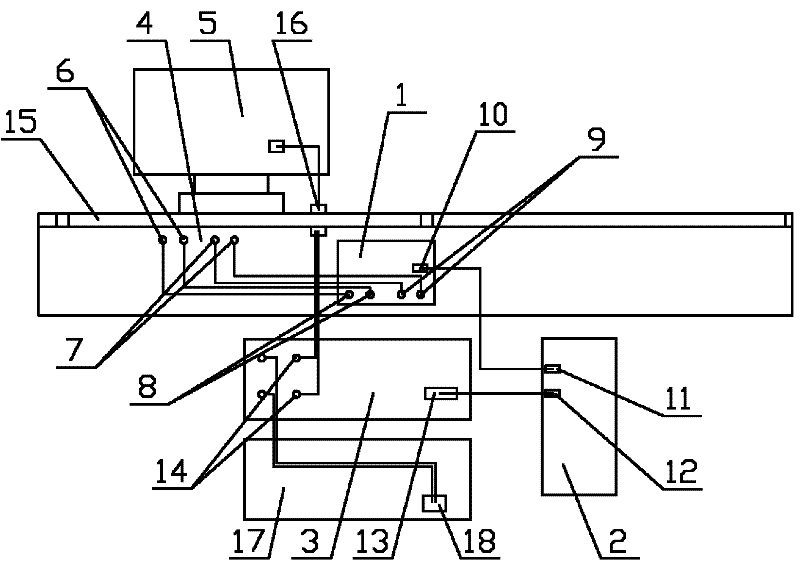

[0024] Display equipment power automatic test system on the production line of the present invention, as figure 1 As shown, it includes a communication card 1, a main control computer 2, a power meter 3, a frequency converter 17 and a PLC controller 4 installed on the production line.

[0025] The PLC controller 4 is provided with an arrival trigger switch and a corresponding arrival signal output terminal 6 that can be triggered by the display device 5 of the arrival station; the PLC controller 4 is also provided with a blocker action for controlling the production line The blocker switch and the outbound signal input terminal 7 for triggering the blocker switch are used to control the action of the blocker to make the display device 5 go out of the station.

[0026] The communication card 1 is provided with an arrival signal input end 8, an outbound signal output end 9 and a communication card parallel port 10, and the arrival signal input end 8 is in phase with the arrival ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com