Weaving torch device for auto wellding

A horizontal swing and automatic welding technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as arc instability, poor welding quality, and reduced weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments of the present invention are described in detail herein with reference to the accompanying drawings.

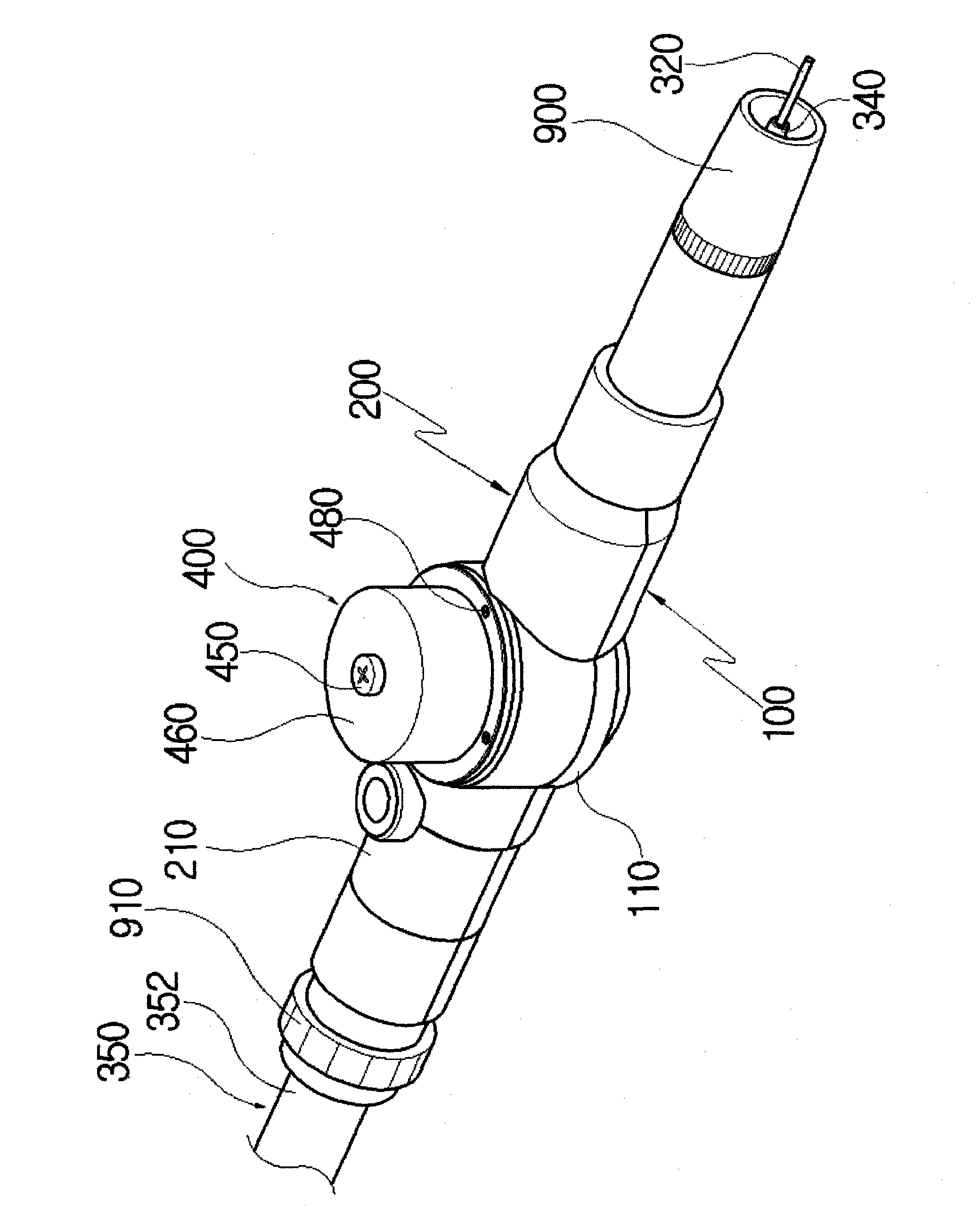

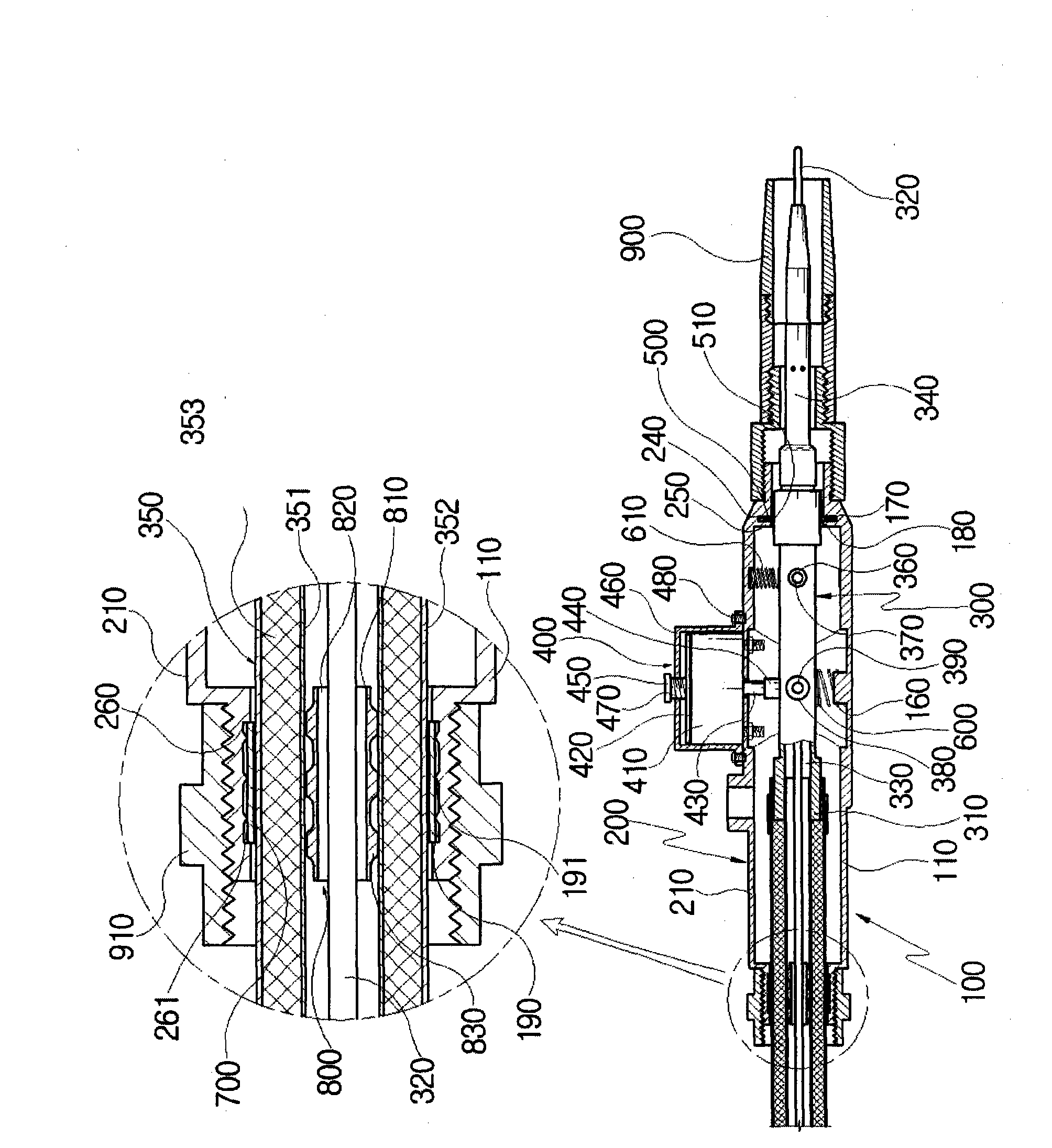

[0053] Reference numerals 900 and 910 in the accompanying drawings represent welding nozzles connected to the front end parts of the upper casing and the lower casing respectively, and screw fastened on the lower ends of the lower casing and the upper casing to fix the lower casing The shell fixing sleeve of the body and the upper shell.

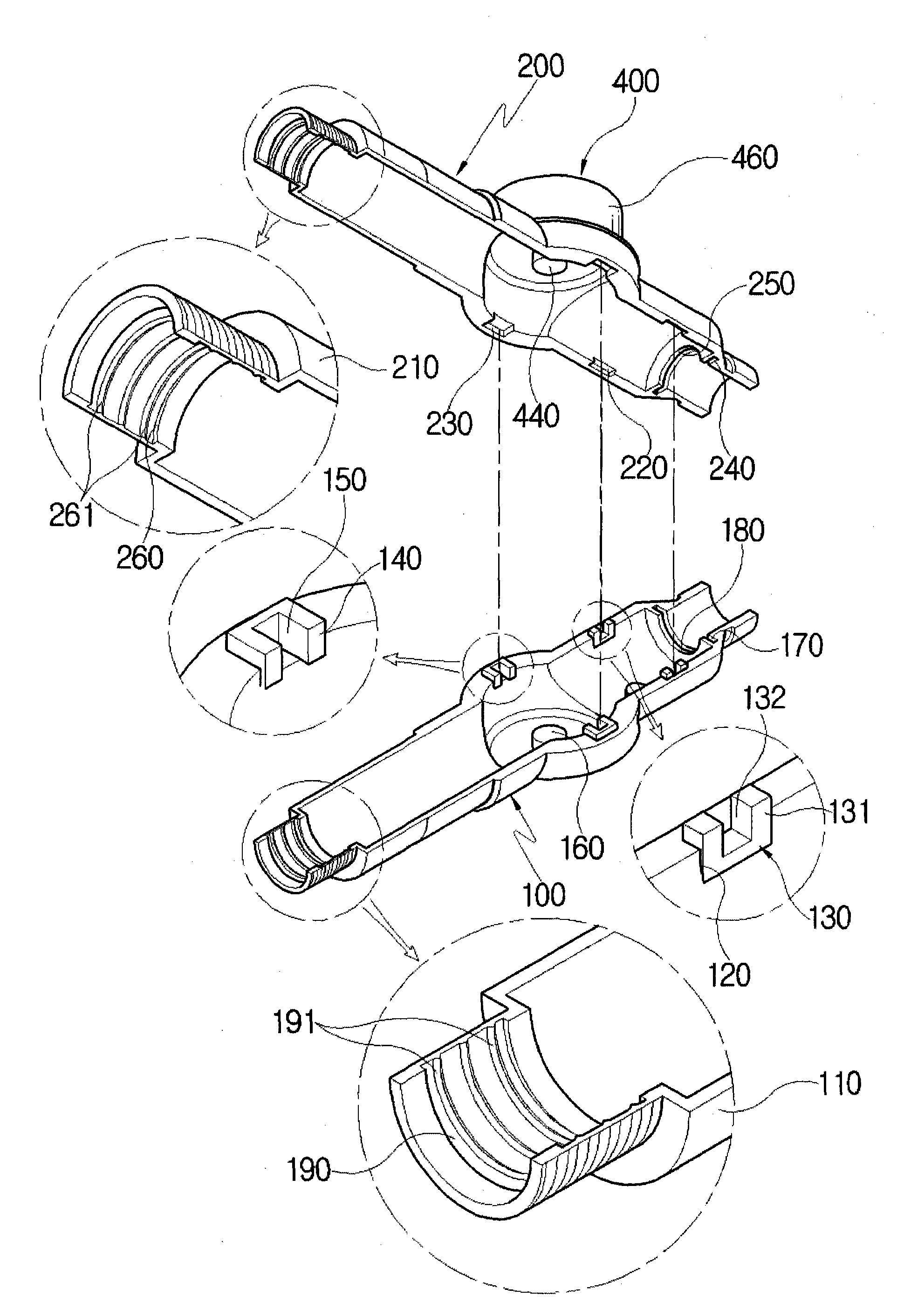

[0054] First, if image 3 As shown, regarding the lower housing 100 of the present invention, the fixing grooves 120 are formed on the two inner sides of the front end portion of the lower body 110 which is long and semicircular; the hinge support member 130 has positioning protrusions protruding upward on both sides 131, and the hinge groove 132 in the middle of the two positioning protrusions 131, so that it is installed in the fixing groove 120; there are fixed protrusions 140 protruding upward on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com