Packaging system with an overcap

A technology for containers, center elements, applied in the field of composite lids for containers, capable of solving complex, inapplicable assembly and retention, single structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

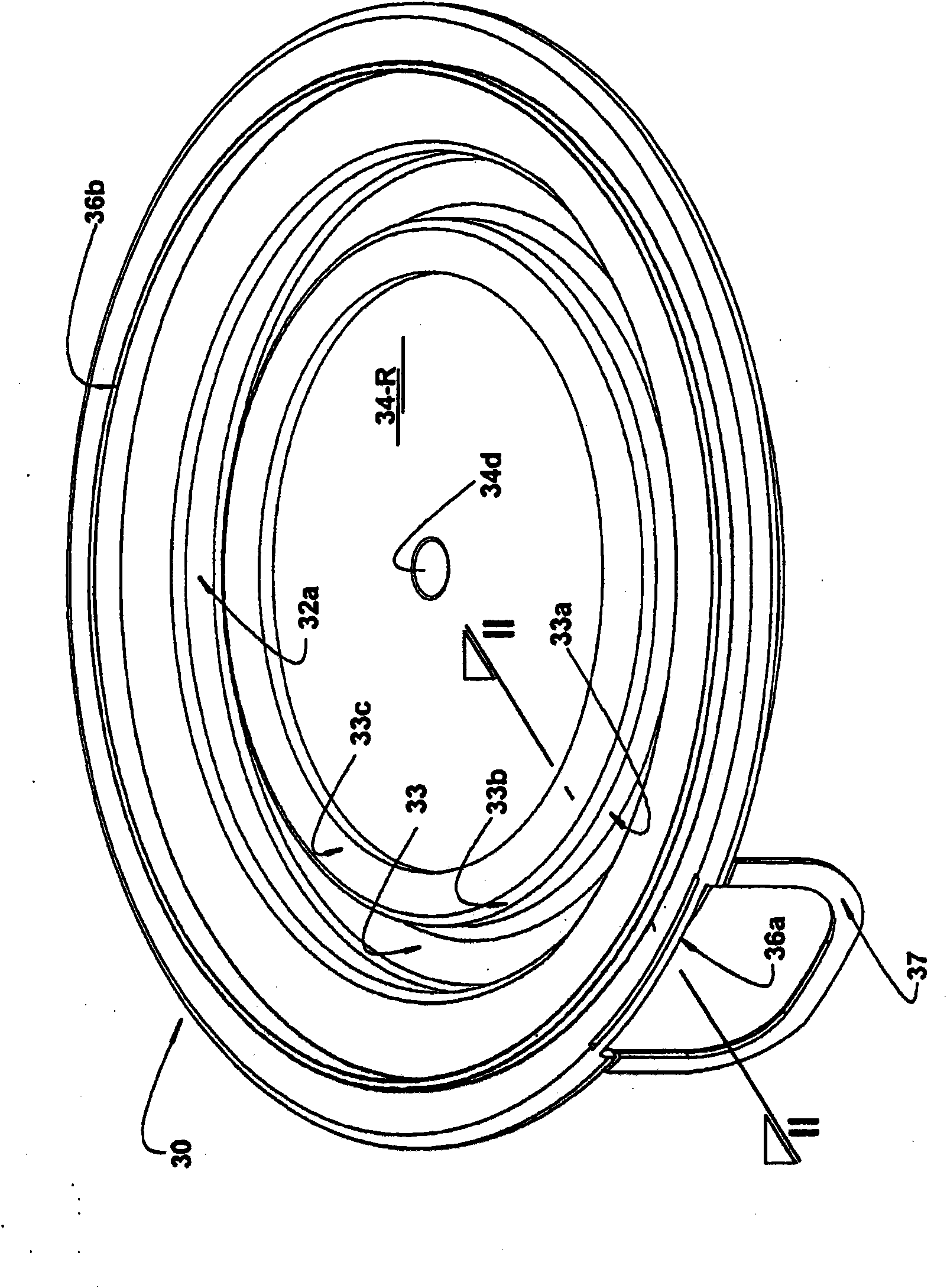

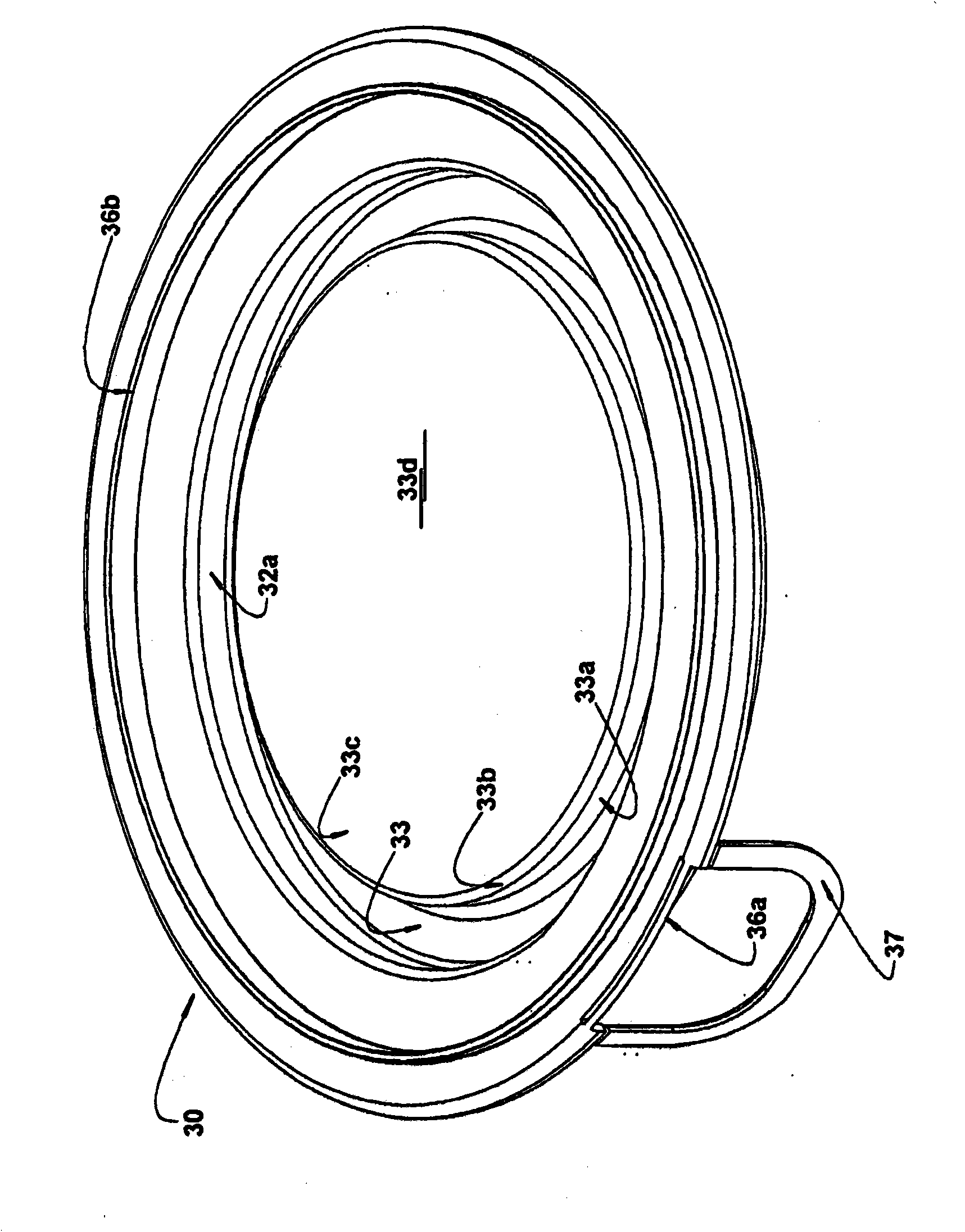

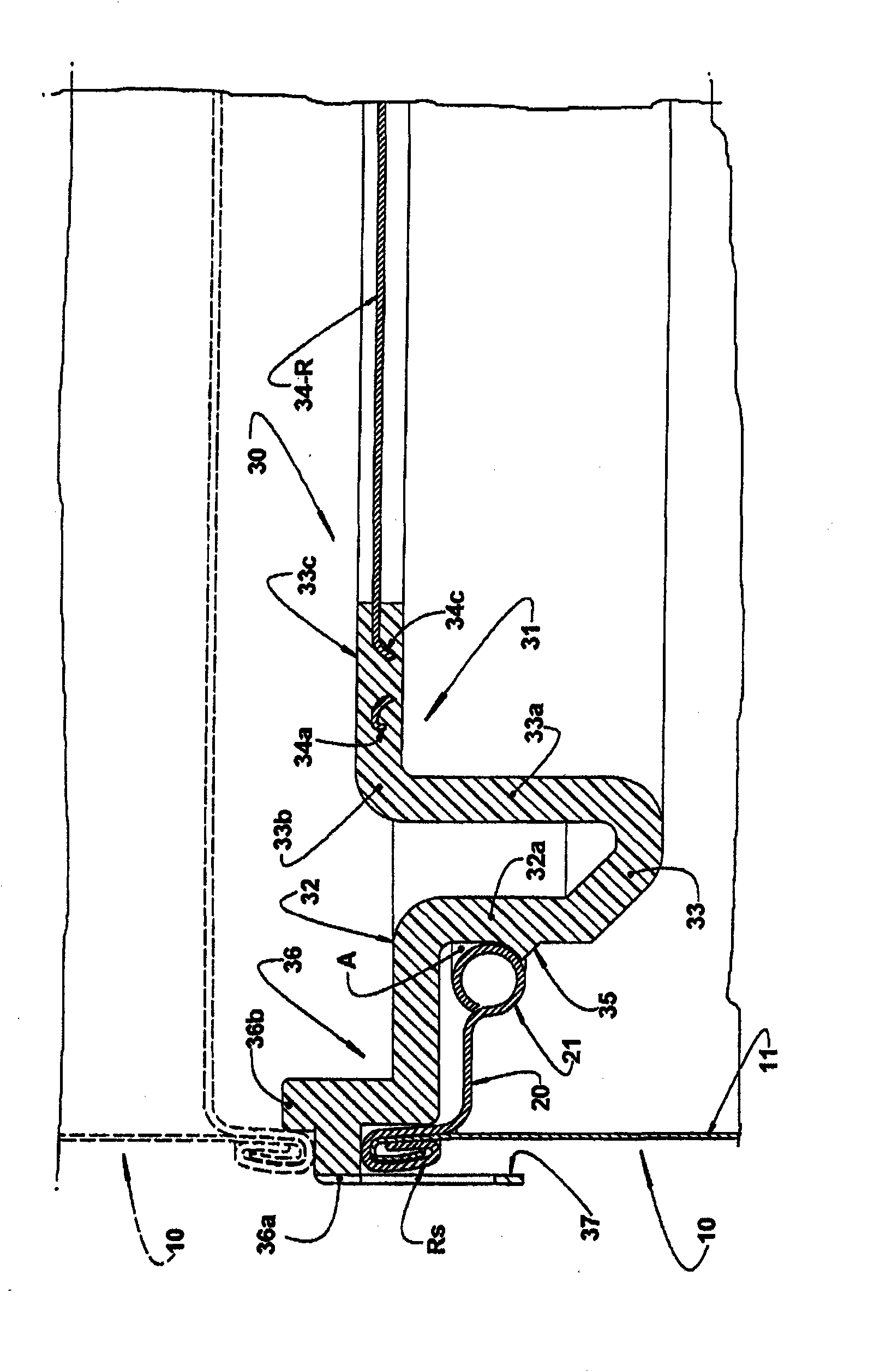

[0029] The composite lid of the invention is applicable to containers of the type comprising a tubular body 10 of sheet metal having a generally cylindrical side wall 11 carrying an annular upper wall also of sheet metal 20, having an opening A surrounded by a base 21 on which a cover 30 is seated and held.

[0030] The annular upper wall 20 can be formed in different ways, for example, as described in Brazilian patent application PI 0504528-2 (PCT / BR2005 / 000232) of the same applicant, by a deformation of the side wall 11 of the tubular body 10, or, as figure 2 with 8 As shown, obtained by suitably stamping from a separate sheet metal and by attaching the upper double-layer joint Rs peripherally to the upper edge of the side wall 11 of the tubular body 10 .

[0031] Independently of the structure applied to the annular upper wall 20 (either a single piece or a double piece joined to the side wall 11 of the tubular body 10), the structure is configured for in its inner periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com