Flexible variable-arm long rotary sprinkling machine

A sprinkler irrigation machine, variable technology, applied in horticulture, botany equipment and methods, cultivation, etc., can solve the problems of reduced service life, inability to shrink the boom, and inability to achieve large-scale shrinkage, so as to increase or decrease the number of nodes and improve effect of rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

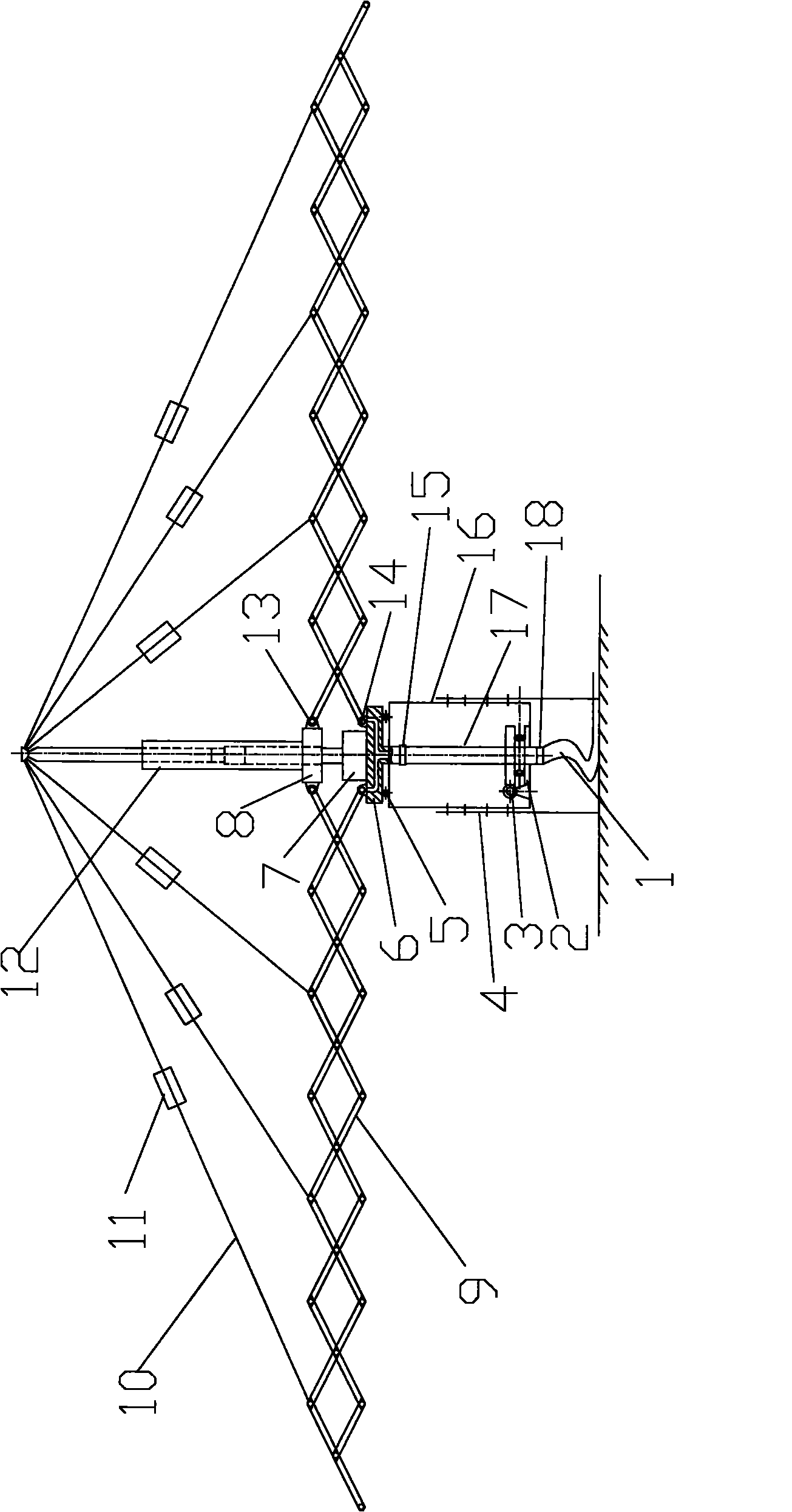

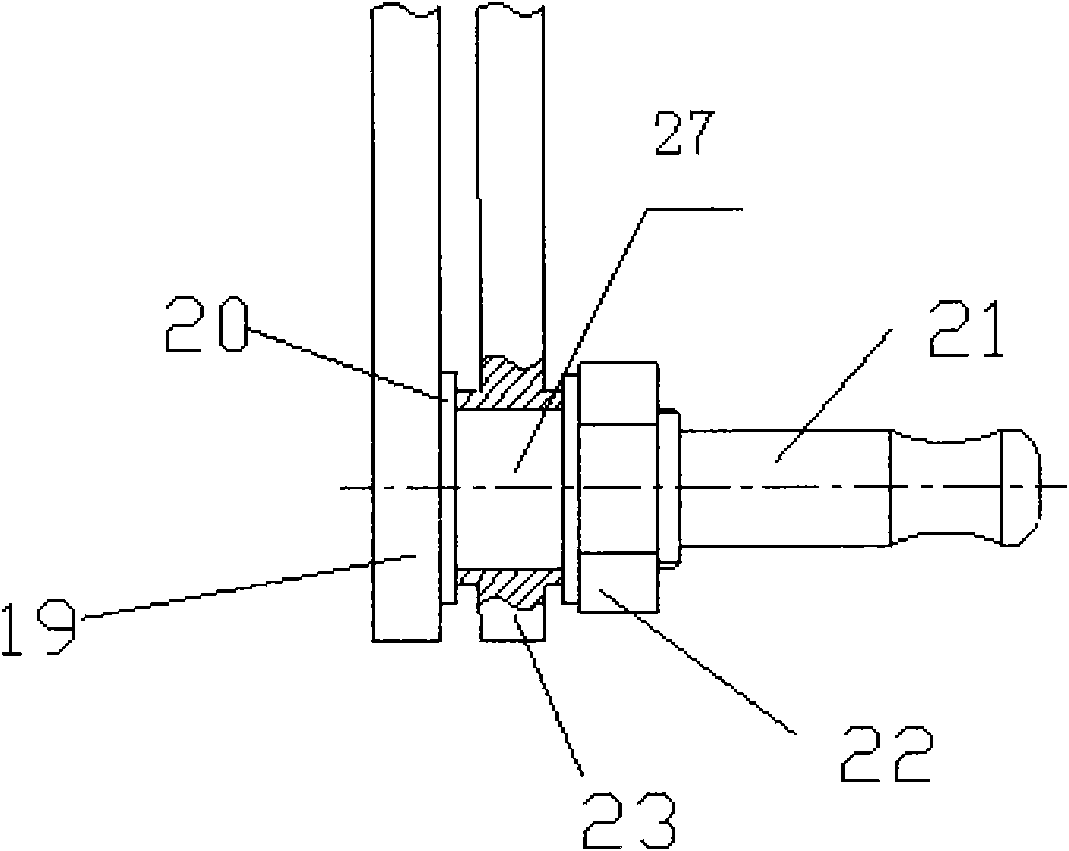

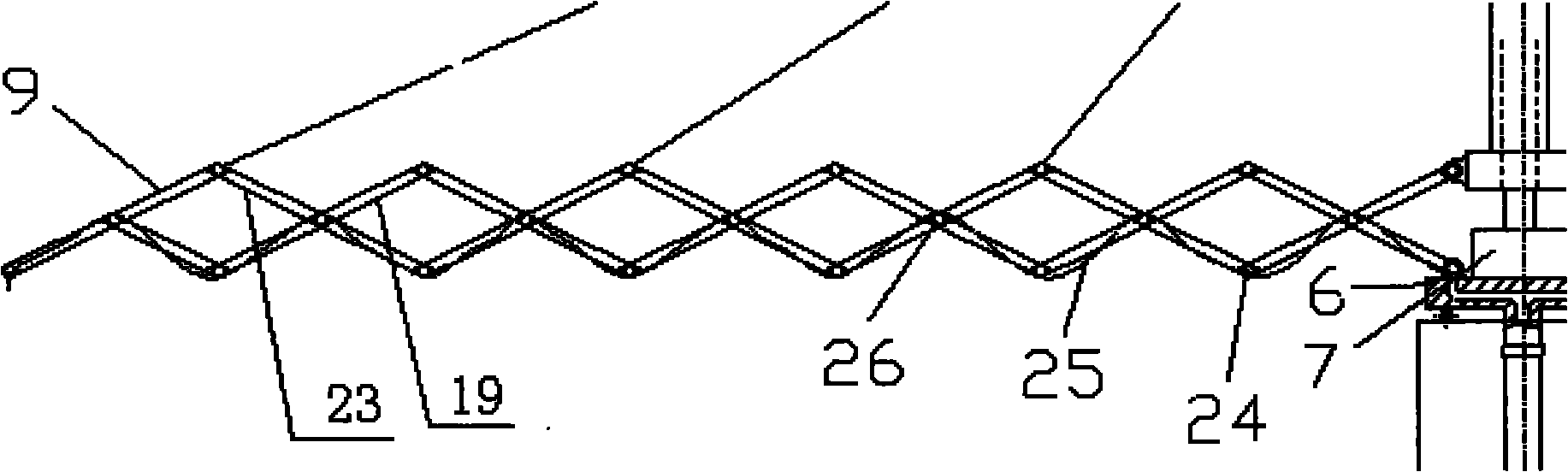

[0021] see figure 1 , the present invention includes a base 4 and a box body 16 set in the base 4, through holes are respectively opened at different heights of the base 4 and the box body 16, and the box body is adjusted by connecting the through holes of different heights on the base 4 and the box body 16 16 height, the height of the box determines the spraying height of the nozzle during irrigation. The bottom of the box body 16 is provided with a bottom plate with a central hole, the main motor 3 is fixed on the bottom plate of the box body 16, and a hollow central rotating shaft 17 connected with the output shaft of the main motor 3 is also provided in the box body 16, The upper and lower ends of the central shaft 17 are equipped with an upper rotary joint 15 and a lower rotary joint 18. The water inlet hose 1 passes through the central hole of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com