Improved locking mechanism of vertical pipe and regulating pipe used for bicycles and body building instruments

A technology of fitness equipment and locking mechanism, which is applied to bicycle frames, bicycle accessories, steering mechanisms, etc., can solve the problems of safety accidents, small locking surface, and low firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

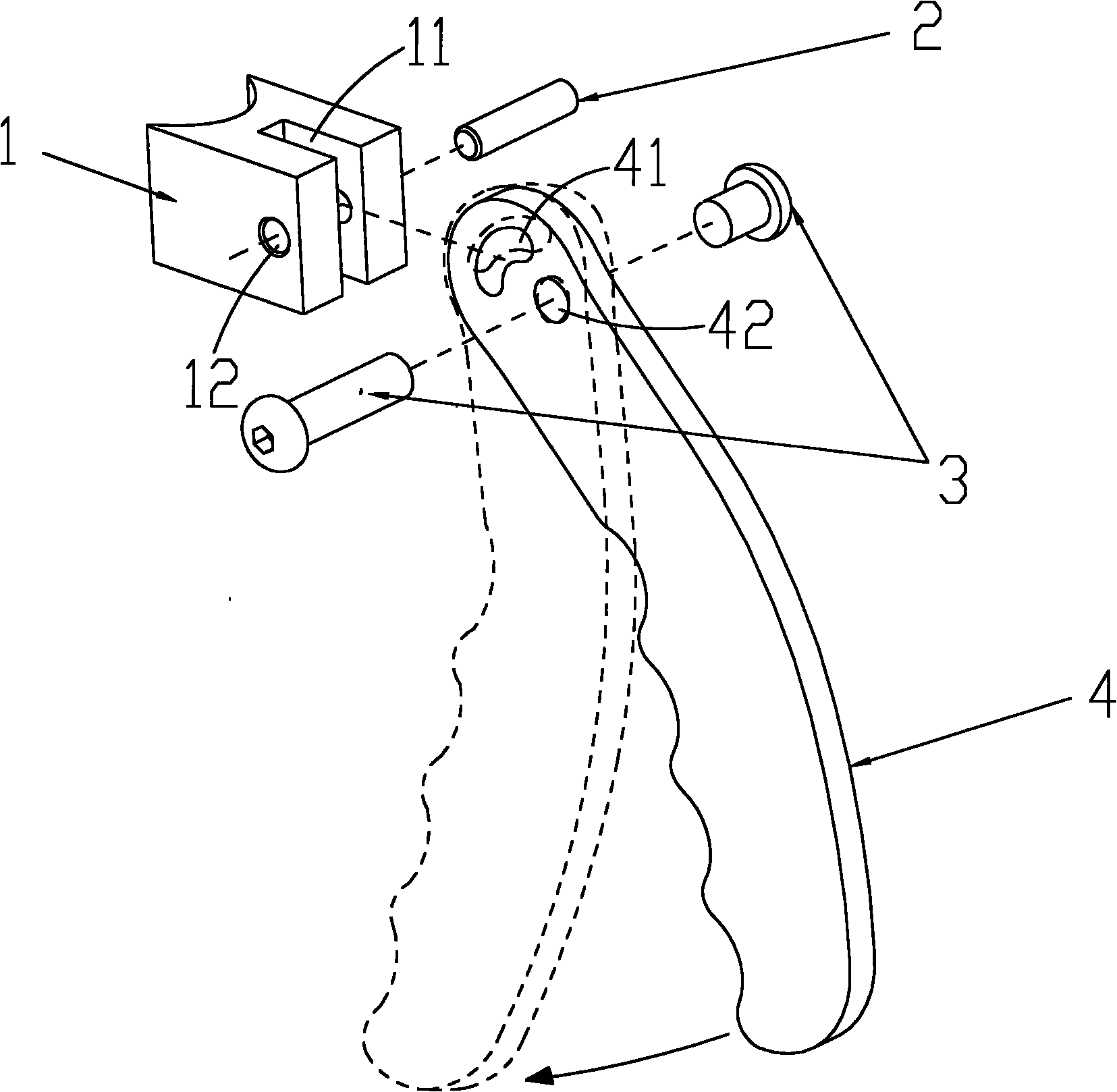

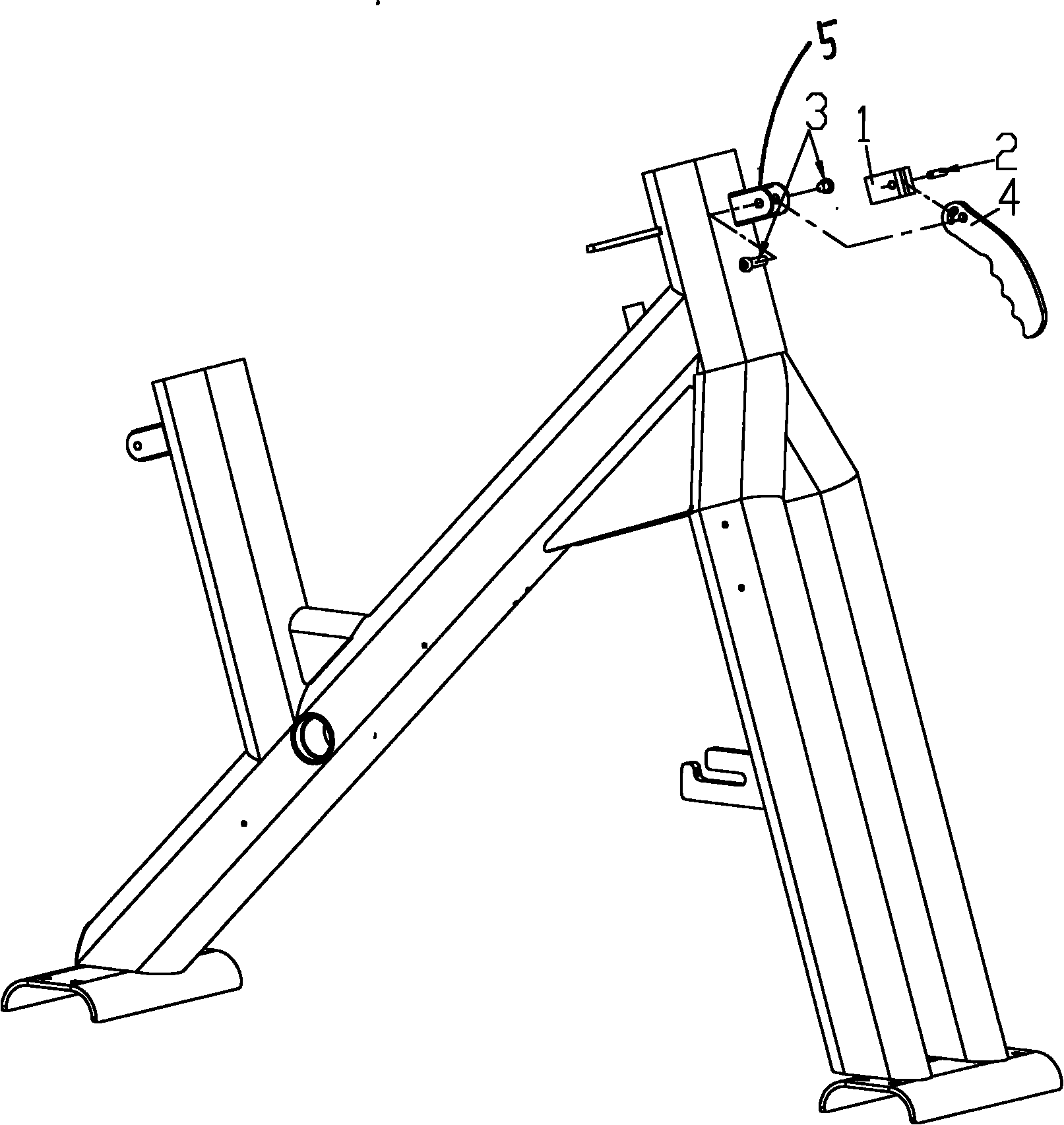

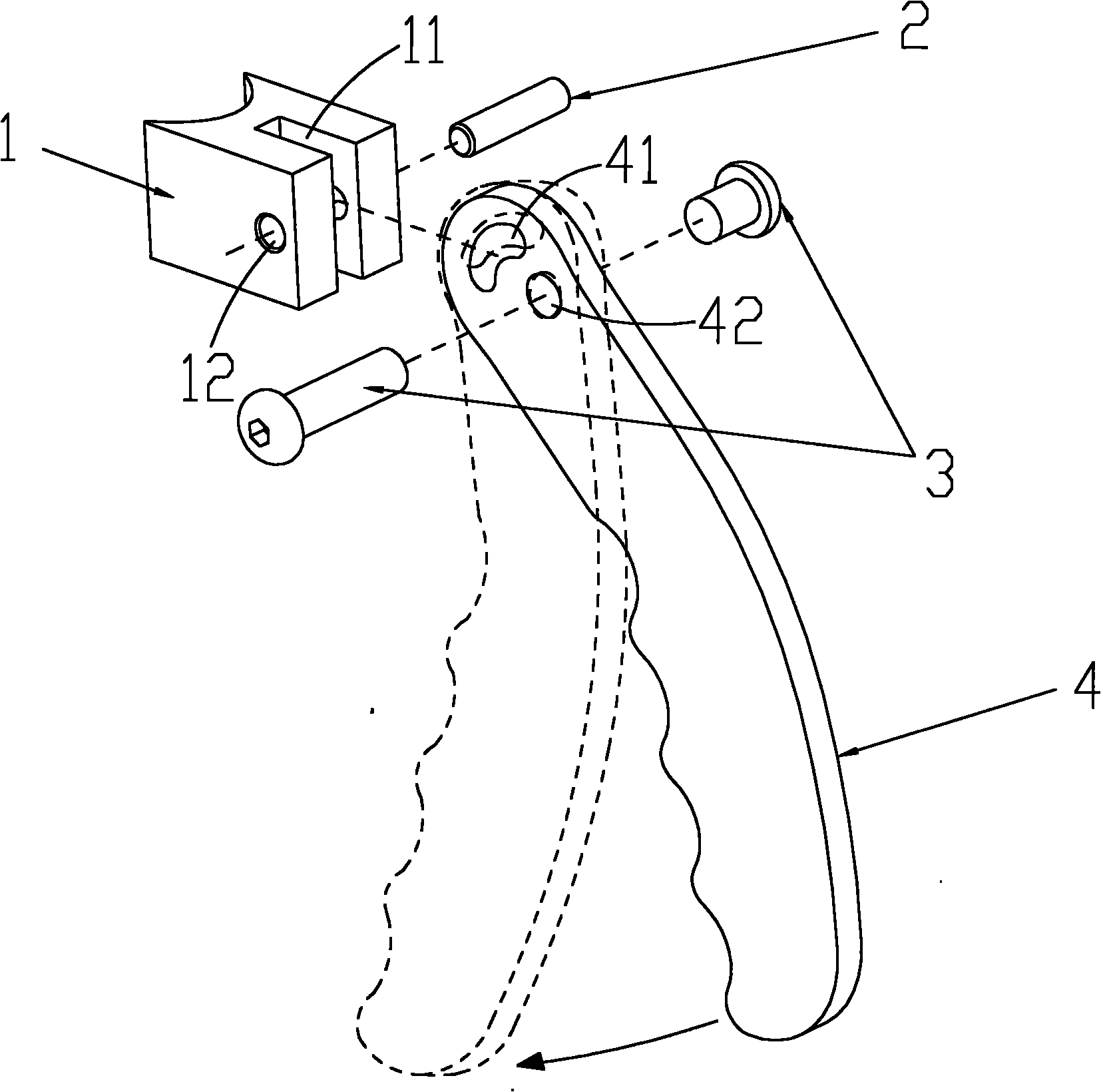

[0011] Embodiment: An improvement of the locking mechanism between the standpipe and the adjustment pipe for bicycles and fitness equipment. The standpipe is freely inserted in the adjustment pipe, and the positions of the standpipe and the adjustment pipe are relatively fixed by the locking mechanism, and a sliding block is provided 1 and the quick release handle 4, the adjustment tube is provided with a sliding tube 5 for the sliding block 1 to move freely, and the sliding block 1 can move freely along the axial direction of the sliding tube in the sliding tube (that is, the sliding block will not come out of the sliding tube) , the slide pipe 5 opens in the standpipe, the slide block 1 can just press against and loosen the standpipe, one end of the quick release handle 4 is provided with an arc-shaped groove 41, and the slide block 1 is provided with (fixed or movable) a positioning The pin 2 and the positioning pin 2 move through the arc groove 41 at the same time. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com