Site installation and debugging method of adjustable bridge steel support and matched steel support

A field debugging, steel bearing technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of poor tensile performance of bridge bearings, complicated height adjustment process, bridge foundation drop, etc., to achieve simple processing, height adjustment and force transmission. The effect of smooth, load-bearing or vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

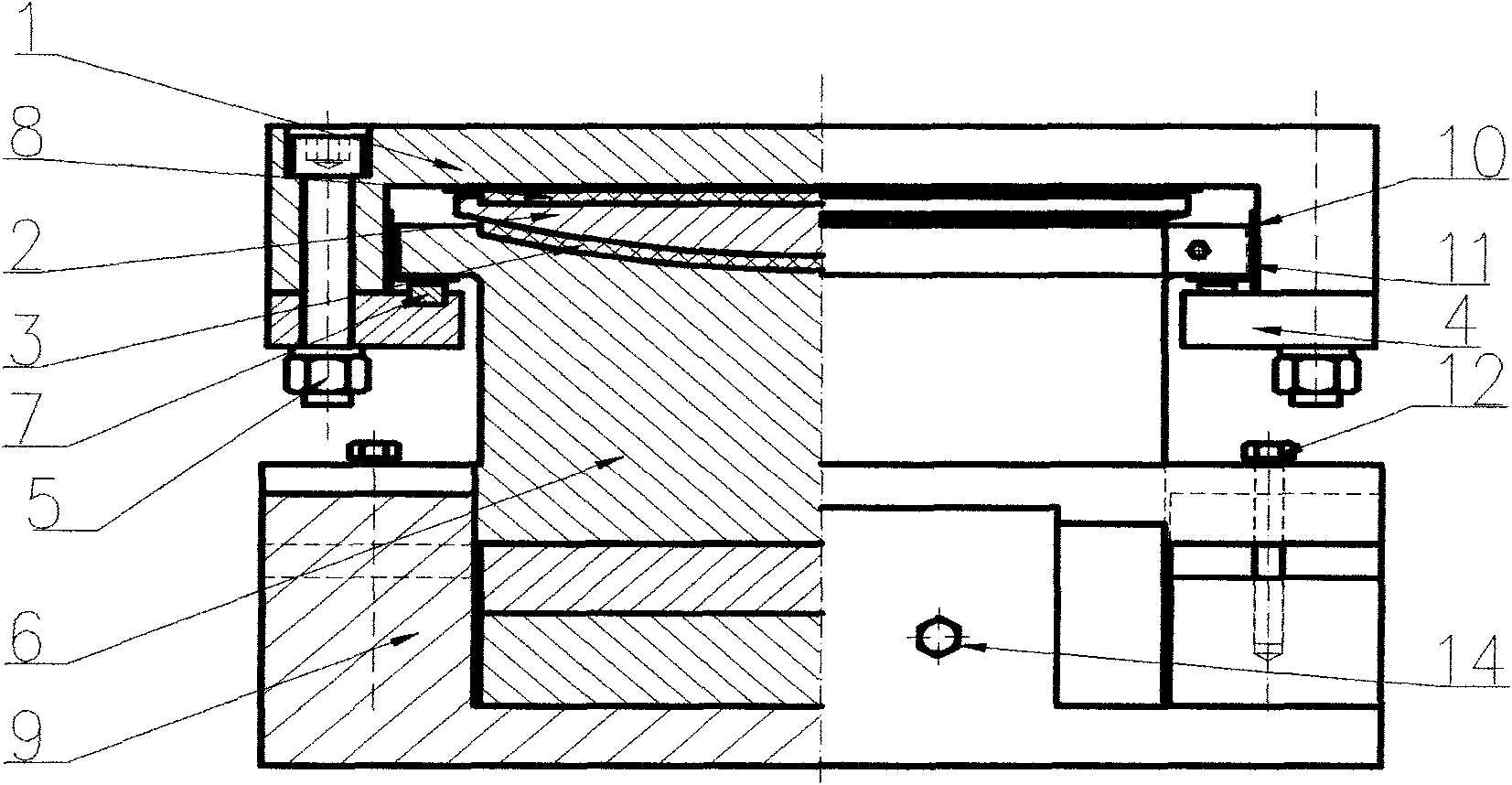

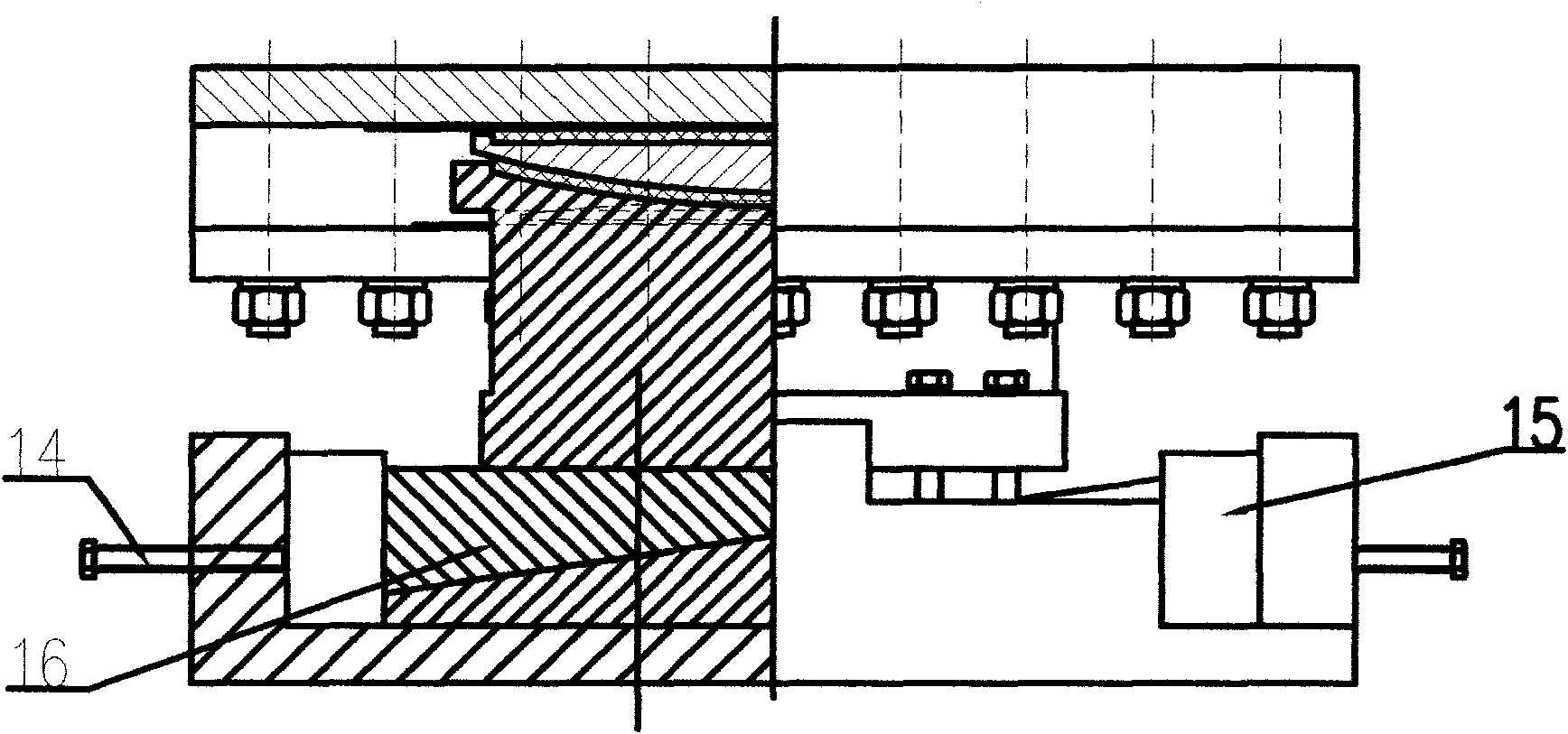

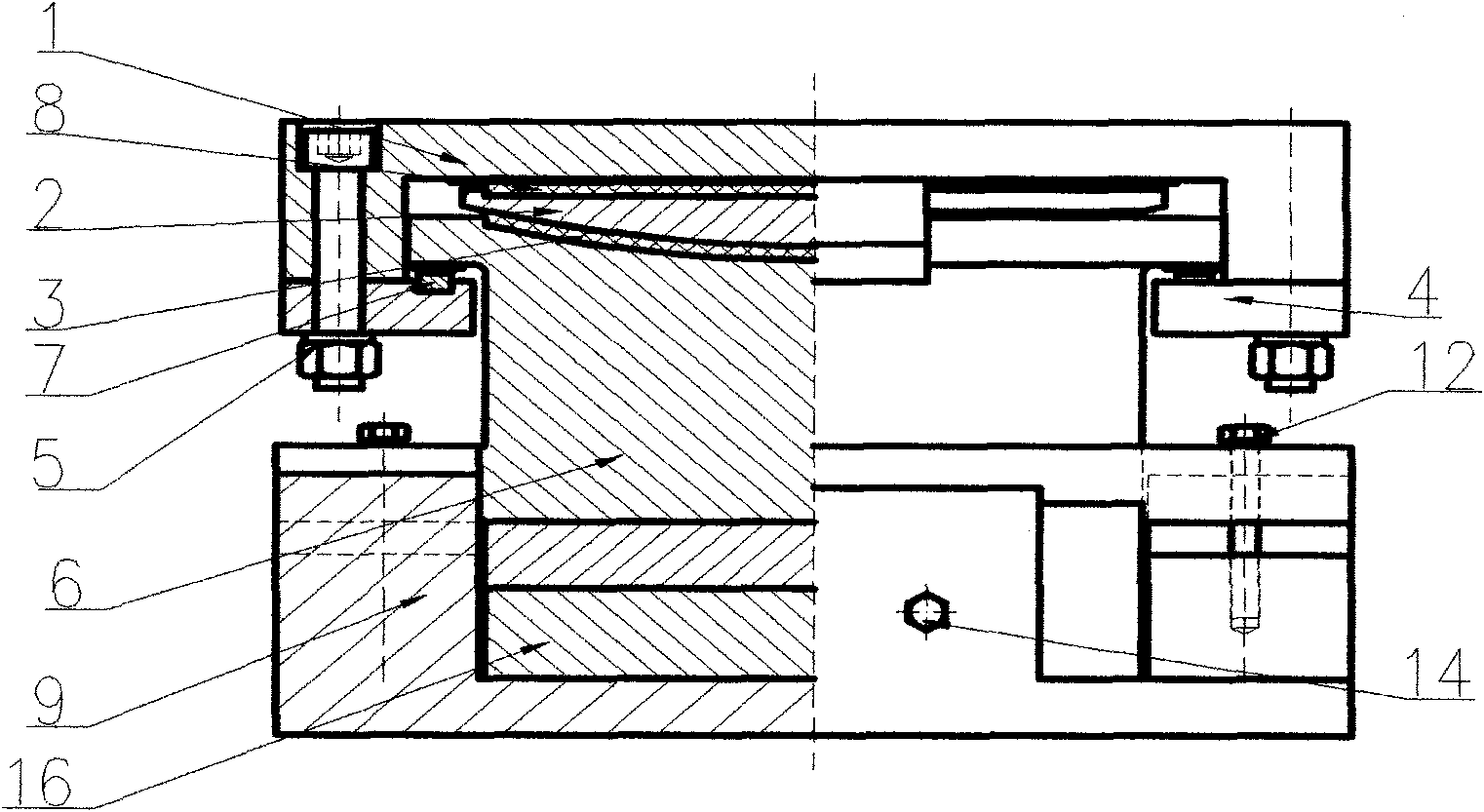

[0020] Referring to the accompanying drawings, the present invention proposes a method for adjusting the height of bridge steel bearings and its supporting steel bearings, which solves the problem of danger brought to the bridge by the decline of the foundation. The technical solution adopted is: an adjustment The method for on-site commissioning and installation of steel bearings of type bridges comprises the following steps:

[0021] 1) Use the height measuring device to accurately measure the online height of the support;

[0022] 2) According to the measured height, select the adjustable steel support to pre-set the height of the support when it is offline;

[0023] 3) With the help of the adjustable stepless height adjustment device mechanism of the steel support, the upper support plate of the steel support meets the engineering design requirements;

[0024] 4) After the bridge is installed and the track is laid, the loading measurement is carried out, and the upper sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com