Reversing frame for welding boiler header

A boiler header and slewing frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large tonnage, large box volume, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

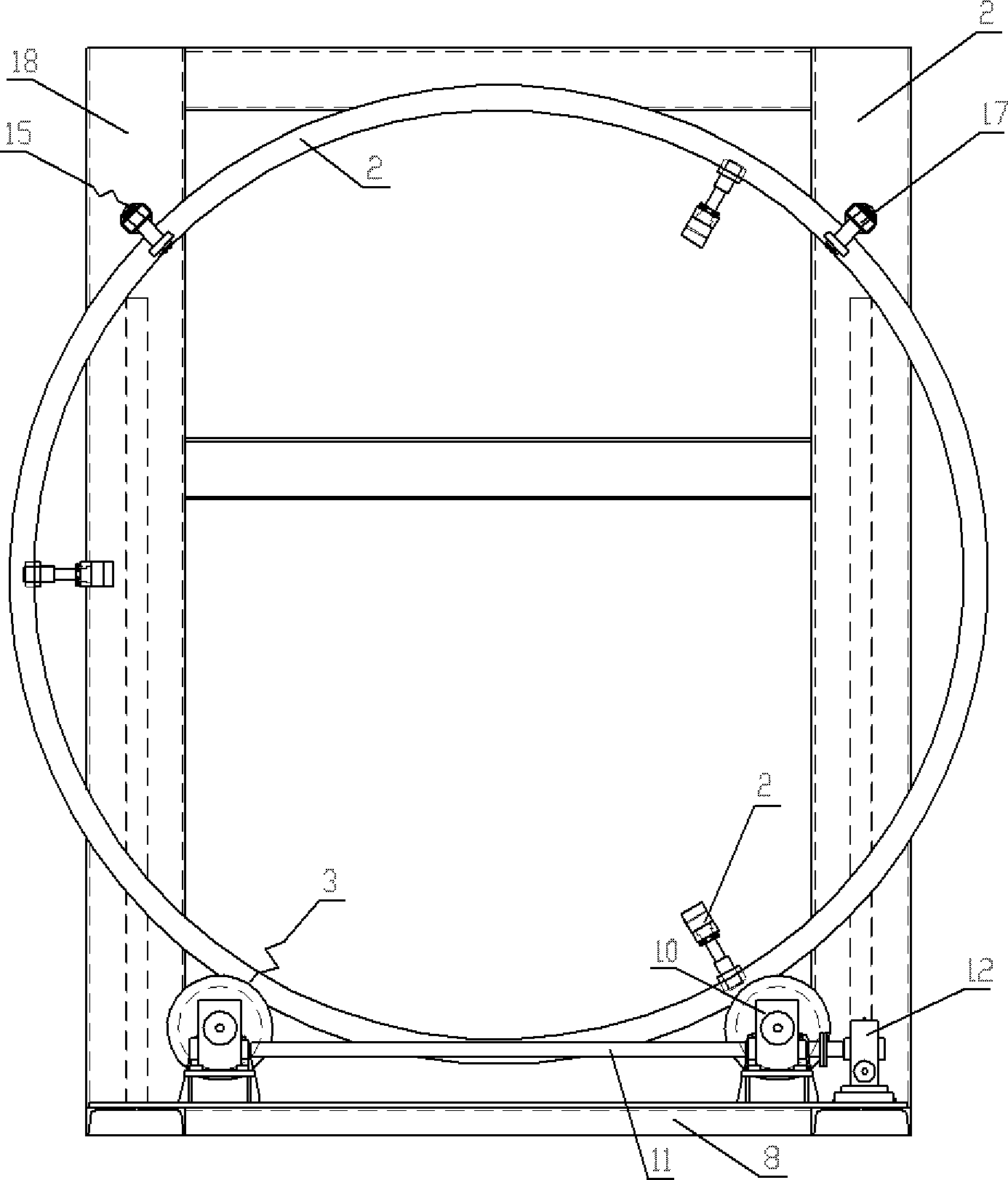

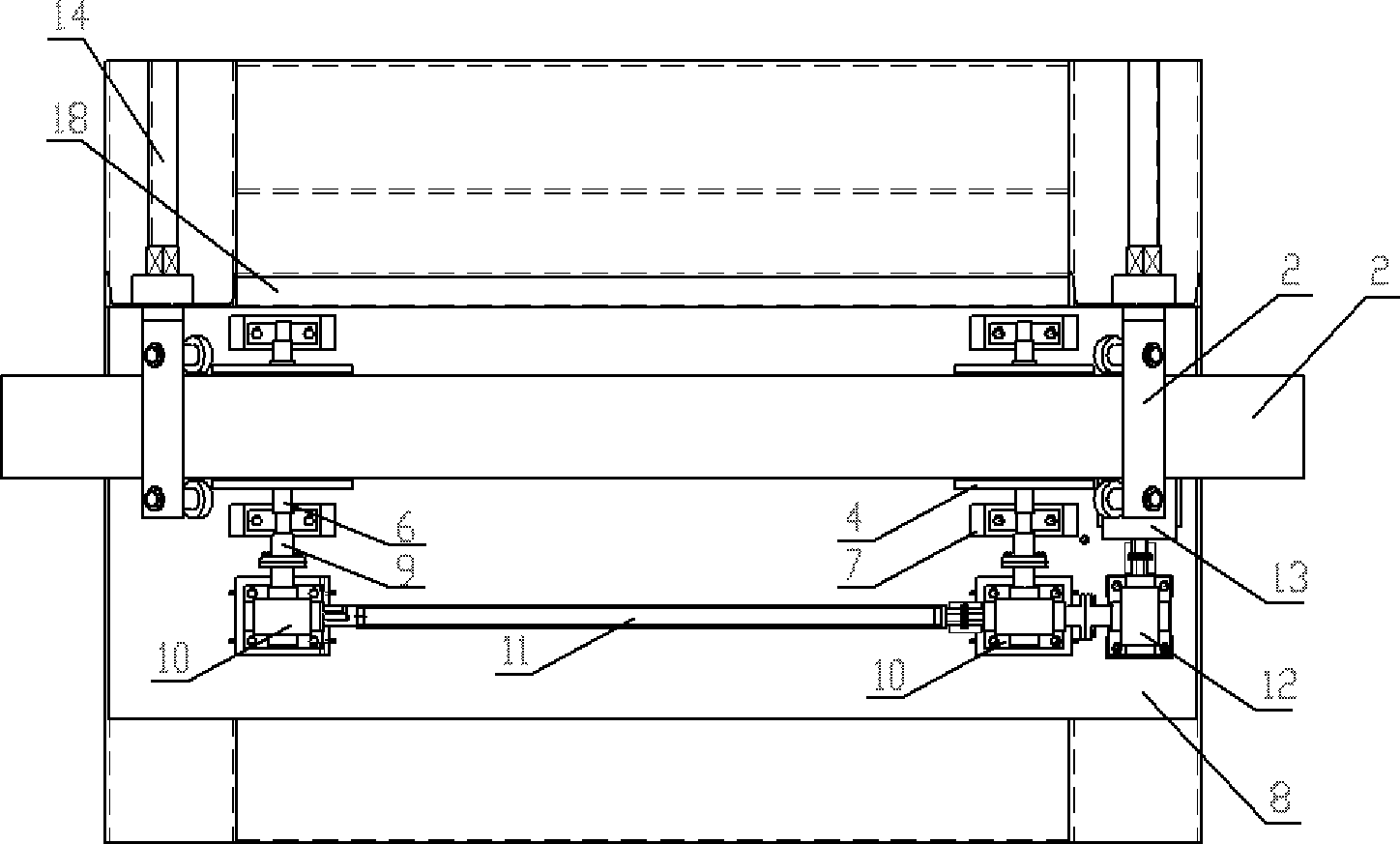

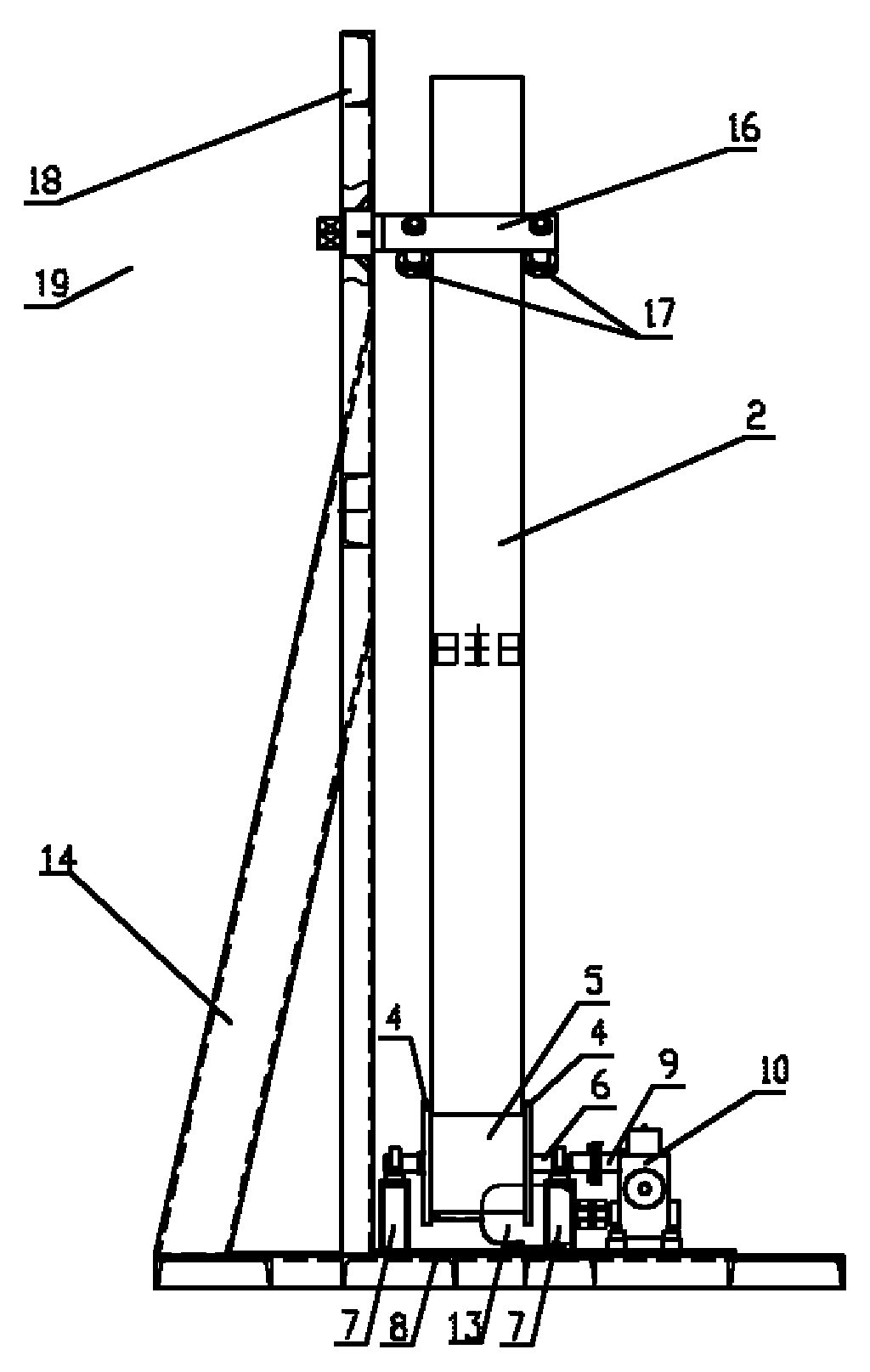

[0016] See figure 1 , figure 2 , image 3 , the inner circular surface of the circular header fixing frame 1 is evenly distributed with fixtures 2, and the outer circular surface of the circular header fixing frame 1 is supported on the guide rail surfaces of two roller guide rails 3. The roller guide rails 3 include vertical plates 4 on both sides, and the middle The roller 5 and the middle roller 5 are set on the guide rail drive shaft 6, the two ends of the guide rail drive shaft 6 are installed on the support seat 7, the outer circular surface of the circular header fixing frame 1 is supported on the middle roller 5, and the support seat 7 is fastened to the connecting machine Frame bottom plate 8, one end of guide rail drive shaft 6 is connected to the longitudinal output shaft of the corresponding transmission shaft seat 10 through a coupling 9, and the transmission shaft seat 10 also includes a transverse output shaft, and the corresponding ends of the transverse outp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap