Welding auxiliary device and welding method

A technology of auxiliary devices and bearing parts, applied in welding equipment, roller electrode welding, resistance welding equipment, etc., can solve the problems of uneconomical use, time-consuming and labor-intensive quality, and high transportation costs, achieving time-saving and labor-saving efficiency and wide applicability. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

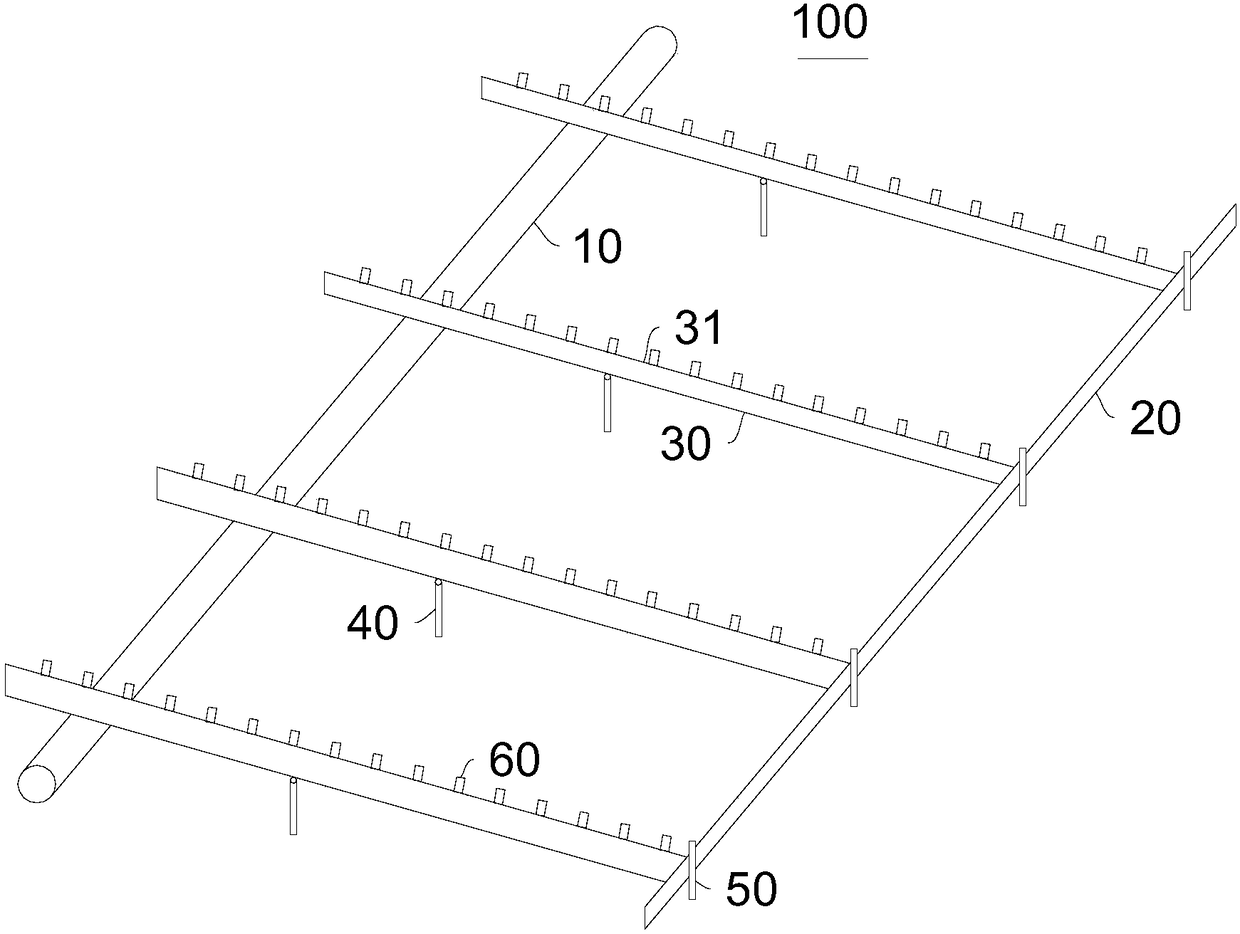

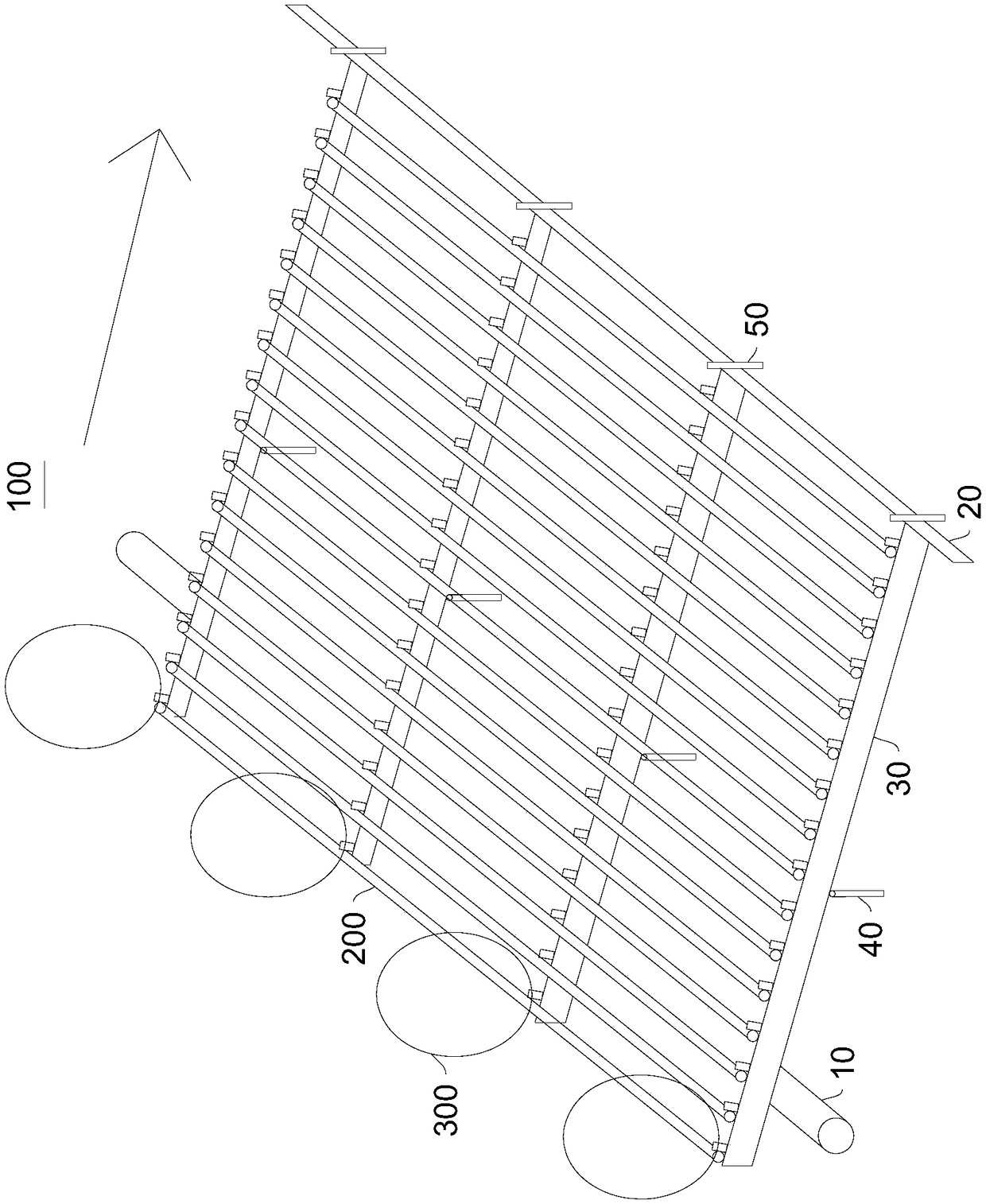

[0041] Please refer to Figure 1-Figure 4 , the present embodiment provides a welding auxiliary device 100, which includes a first fixing part 10, a second fixing part 20 and a plurality of supporting parts 30, one end of the supporting part 30 is connected with the first fixing part 10, and the supporting part 30 The other end is connected with the second fixing part 20, and the supporting part 30 is provided with a plurality of fixing parts 31 for fixing the main rib 200, and the fixing parts 31 are distributed at intervals along the length direction of the supporting part 30, and the plurality of supporting parts 30 are arranged along the first fixing part. 10 are spaced along the length direction.

[0042] In this embodiment, the first fixing part 10 is a spiral steel pipe, the second fixing part 20 is a channel steel, and the bearing part 30 is an I-shaped steel. These materials are common in construction sites. Of course, in other embodiments, any rod or pipe can be use...

Embodiment 2

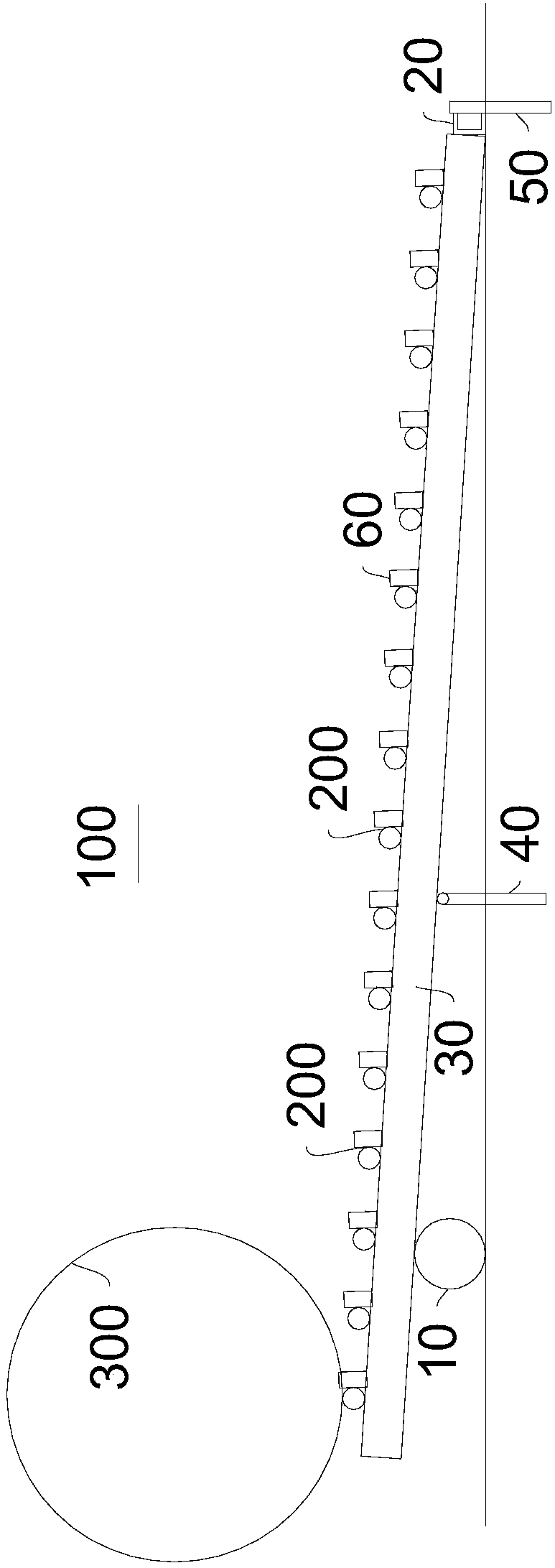

[0071] This embodiment also provides a welding method, which uses the above-mentioned welding auxiliary device 100 , and the structure of the welding auxiliary device 100 can refer to Embodiment 1.

[0072] The method includes:

[0073] setting the carrier 30 obliquely relative to the horizontal plane;

[0074] Place the main ribs 200 on the fixed part 31 in sequence, so that multiple main ribs 200 are distributed side by side;

[0075] Place a plurality of reinforcement rings 300 on the main rib 200, so that the reinforcement ring 300 is placed correspondingly to the carrier 30, and the axial direction of the parallel reinforcement rings 300 is consistent with the axial direction of the main rib 200;

[0076] First, the main ribs 200 located on the carrier 30 close to the first fixing part 10 are welded to a plurality of reinforcement rings 300, so that the reinforcement rings 300 roll relative to the carrier 30, and the main ribs 200 on the carrier 30 are welded to multiple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap