Inkjet printing correction method, inkjet printing apparatus and multifunctional one-piece machine

A technology of an inkjet printing device and a correction method, which can be applied to the printing device, printing and other directions, and can solve the problems of file distortion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

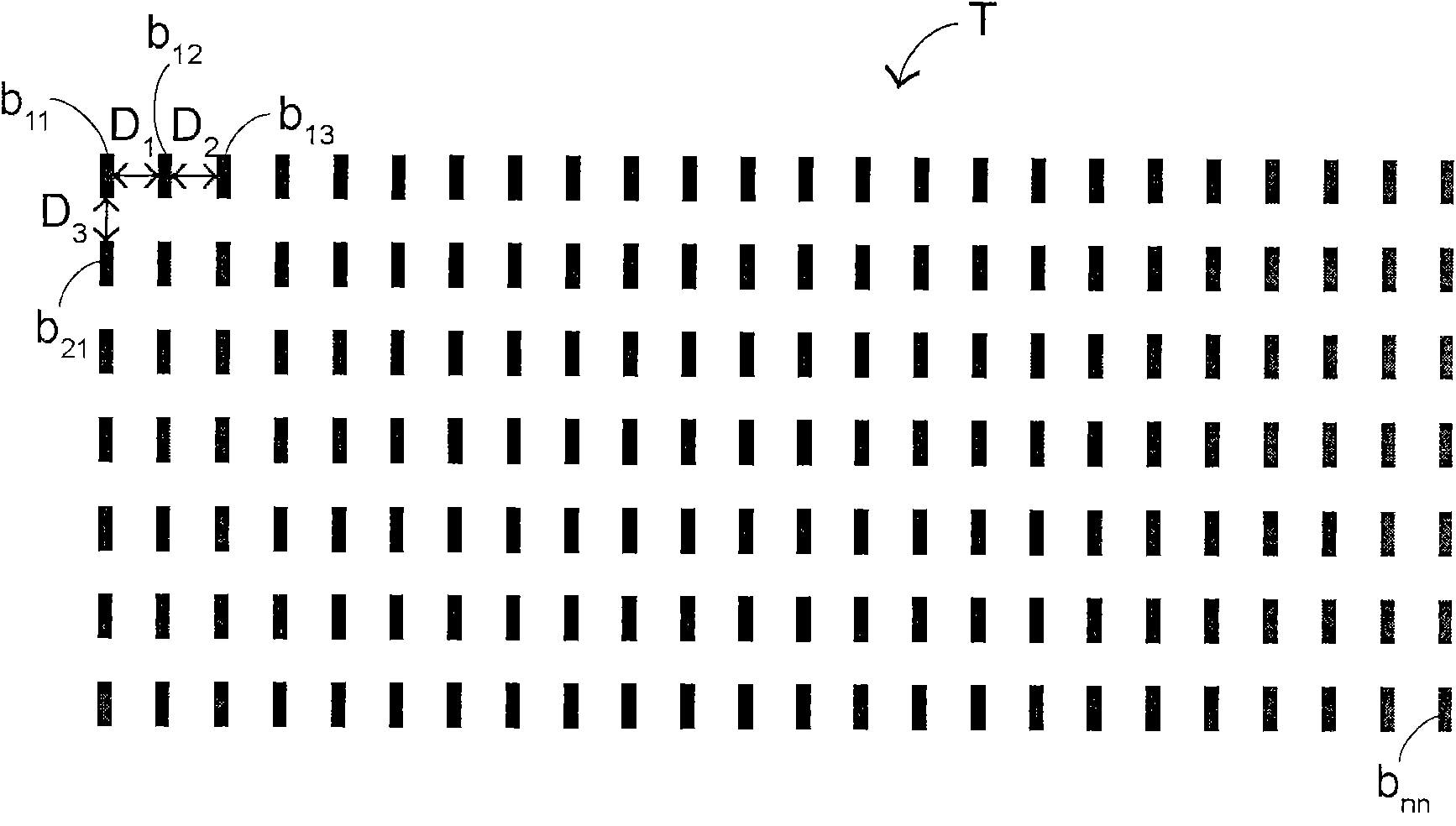

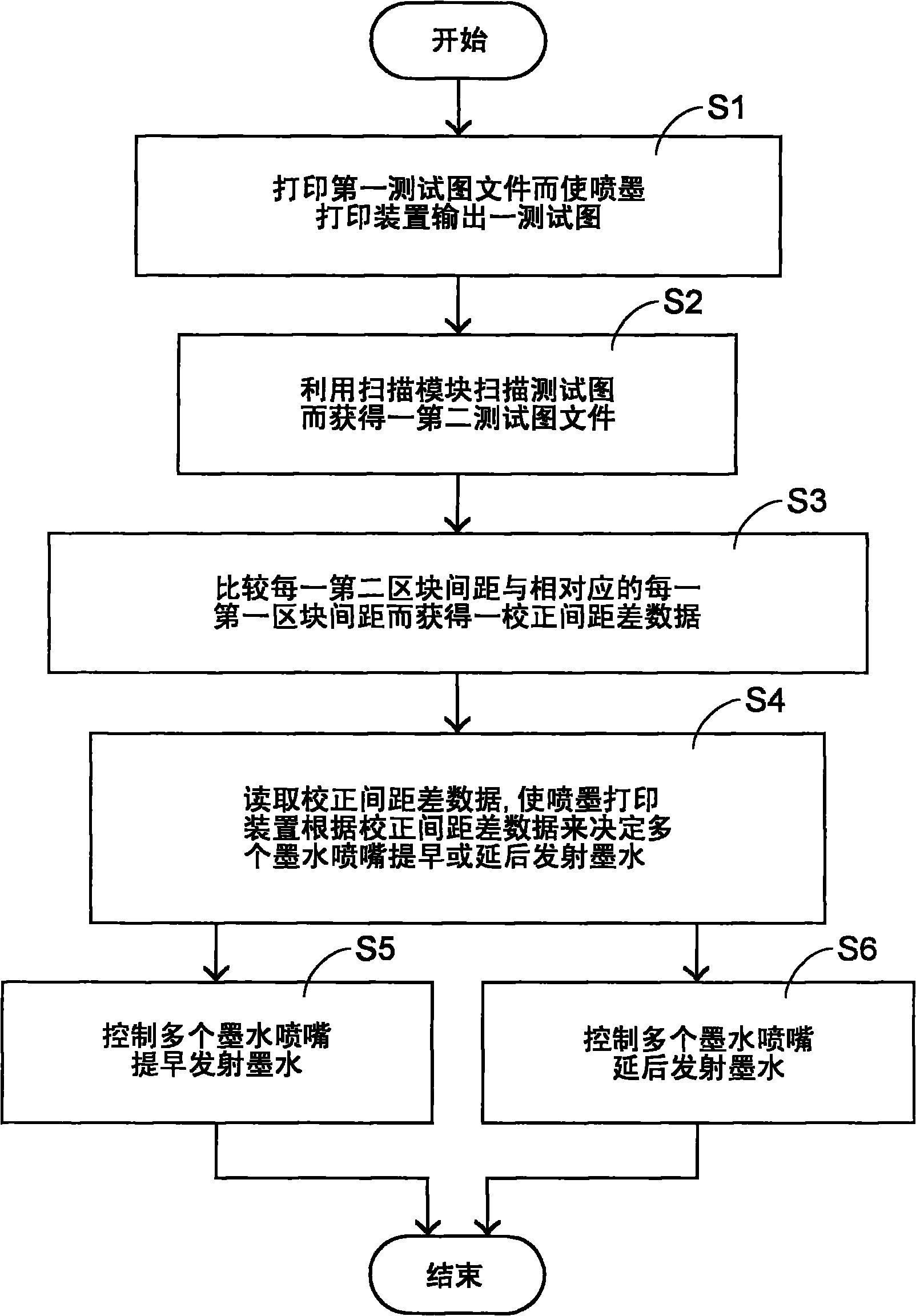

[0041] In view of the deficiencies of known technologies, the present invention provides a method for correcting inkjet printing without distortion, please refer to image 3 , which is a block flow chart of the inkjet printing correction method in a preferred embodiment of the present invention. image 3 Among them, after the inkjet printing starts, enter step S1, step S1 is to print the first test pattern file and make the inkjet printing device output a test pattern, and then step S2 is to use the scanning module to scan the test pattern to obtain a second test pattern file , step S3 is to compare each second block pitch with each corresponding first block pitch to obtain a corrected pitch difference data, and step S4 is to read the corrected pitch difference data, so that the inkjet printing device can difference data to determine whether a plurality of ink nozzles emit ink earlier or later, and when the correction gap difference data shows that any first block pitch in a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com