Electric heating skirting

A technology of baseboards and electric heating wires, which is applied to ohmic resistance heating parts, heating elements, buildings, etc., can solve the problems of unreasonable heating distribution in the room, occupying valuable space in the room, and low heating thermal efficiency, so as to shorten the construction period , high electrothermal conversion efficiency and comfortable environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

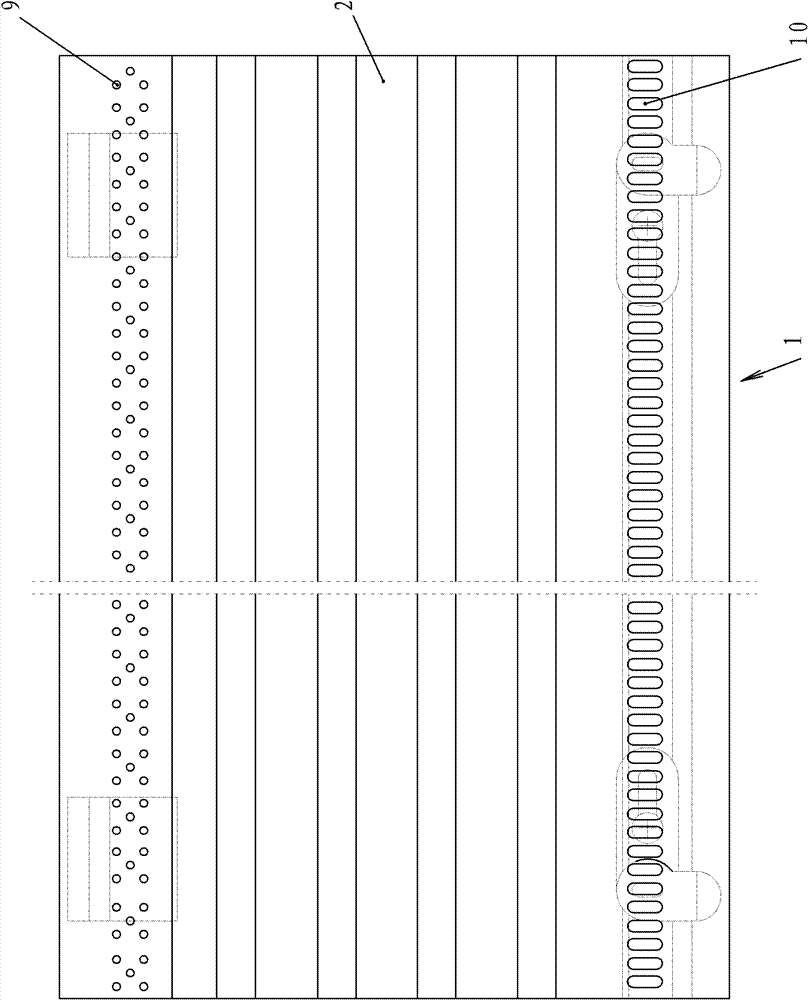

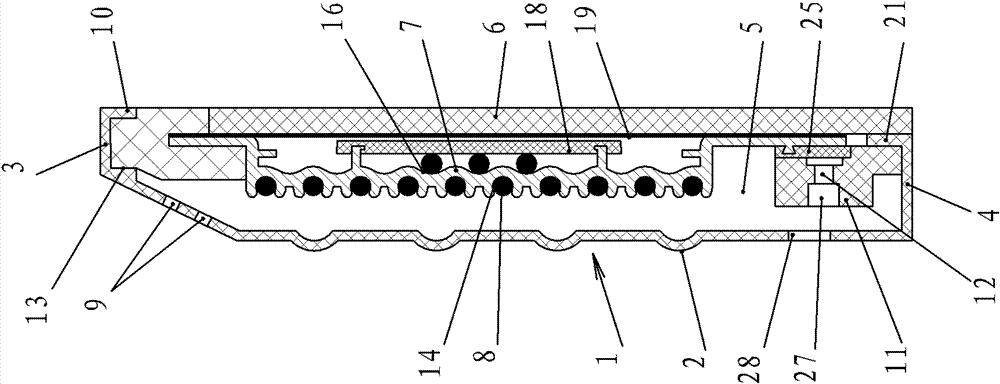

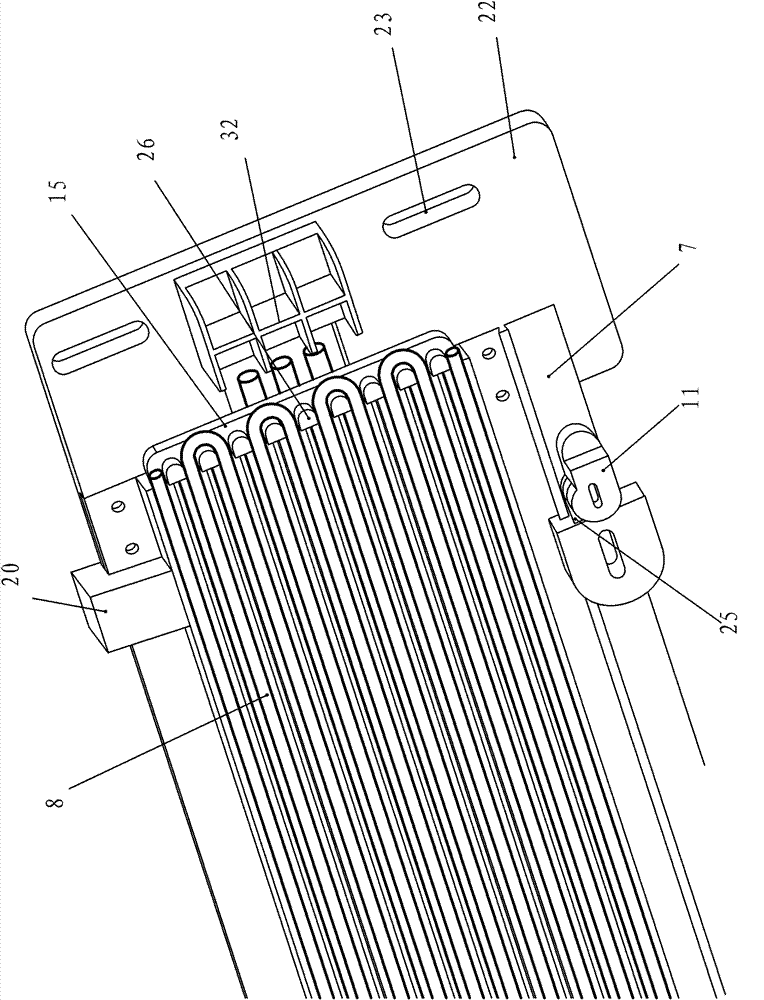

[0020] see figure 1 with figure 2 , the electric heating skirting line of the present invention comprises a skirting board 1, the length of the skirting board 1 is 500-6000mm, the height is 80-450mm, and the thickness is 0.5-2.5mm, and the length of the skirting board 1 per meter The electric heating power is 20-500 watts. The kick cover 1 includes the front panel 2, the top panel 3 and the bottom panel 4. The front panel 2, the top panel 3 and the bottom panel 4 are made of aluminum alloy plate or plastic plate. The surface is arranged vertically, the top of the front panel 2 is connected to the front end of the top panel 3, the bottom of the front panel 2 is connected to the front end of the bottom panel 4, and the front panel 2, the top panel 3 and the bottom panel 4 are arranged along the rear portion of the skirting board 1. A through groove 5 is formed horizontally, and the notch of the through groove 5 is provided with a heat-insulating cover plate 6, which can be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com