Humidification fan

A fan and pressurized fan technology, applied in air humidification systems, heating methods, lighting and heating equipment, etc., can solve the problems of destroying the atomization effect, not needing too much water storage volume, wasting space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

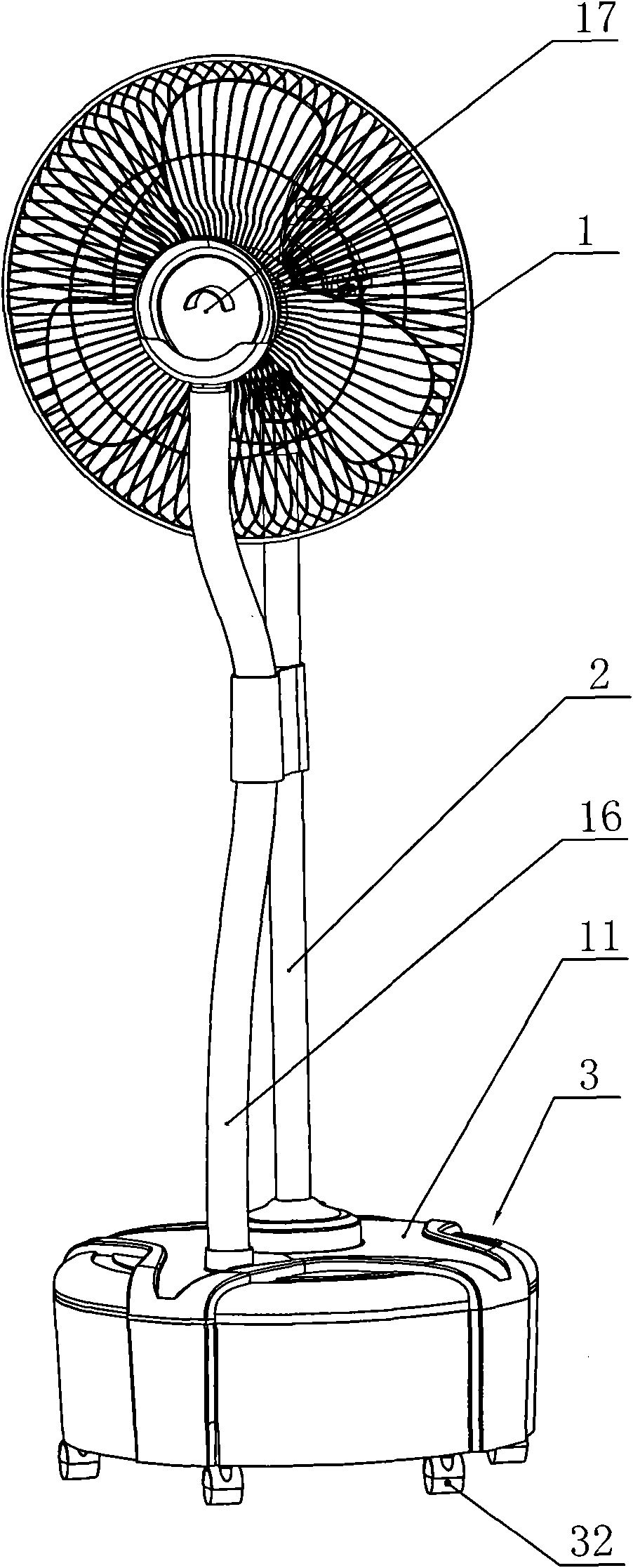

[0038] Such as figure 1 As shown, the humidifying fan includes a fan head 1 , a support column 2 of the fan head and a base 3 , and the support column 2 is supported on the base 3 . The fan head 1 includes a motor main body, fan blades connected to the output shaft of the motor, and a safety net cover fixedly connected to the motor main body and clamped between the fan blades. The central part of the safety net cover is fixed Be connected with diffuse mist cover 17. The fan head 1 is connected to the top of the support column 2 through a positioning device provided on the motor body and can swing on the support column 2 . The support column 2 is made of steel pipe, and conductive wires or control wires (not shown in the figure) are distributed in its lumen.

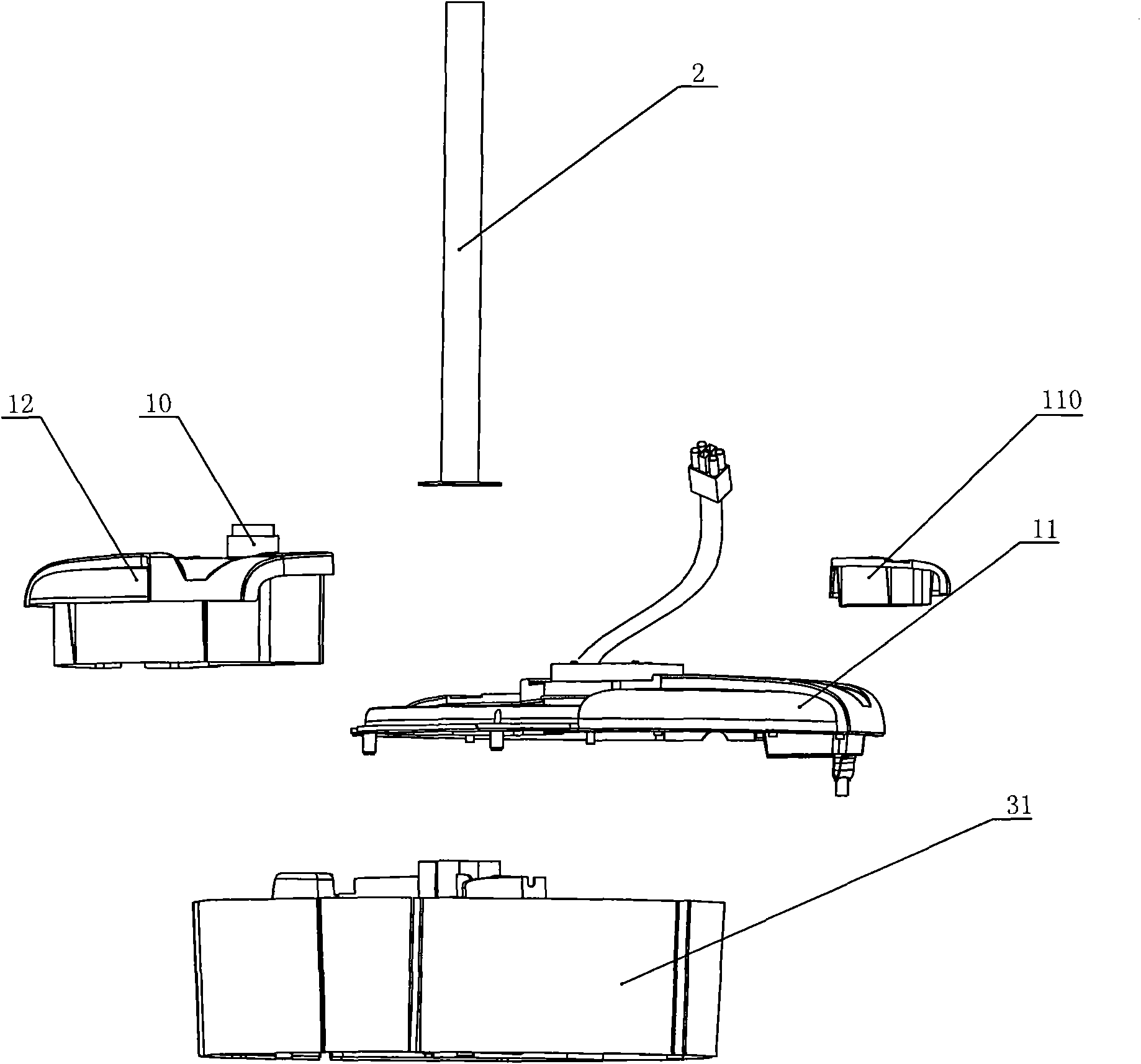

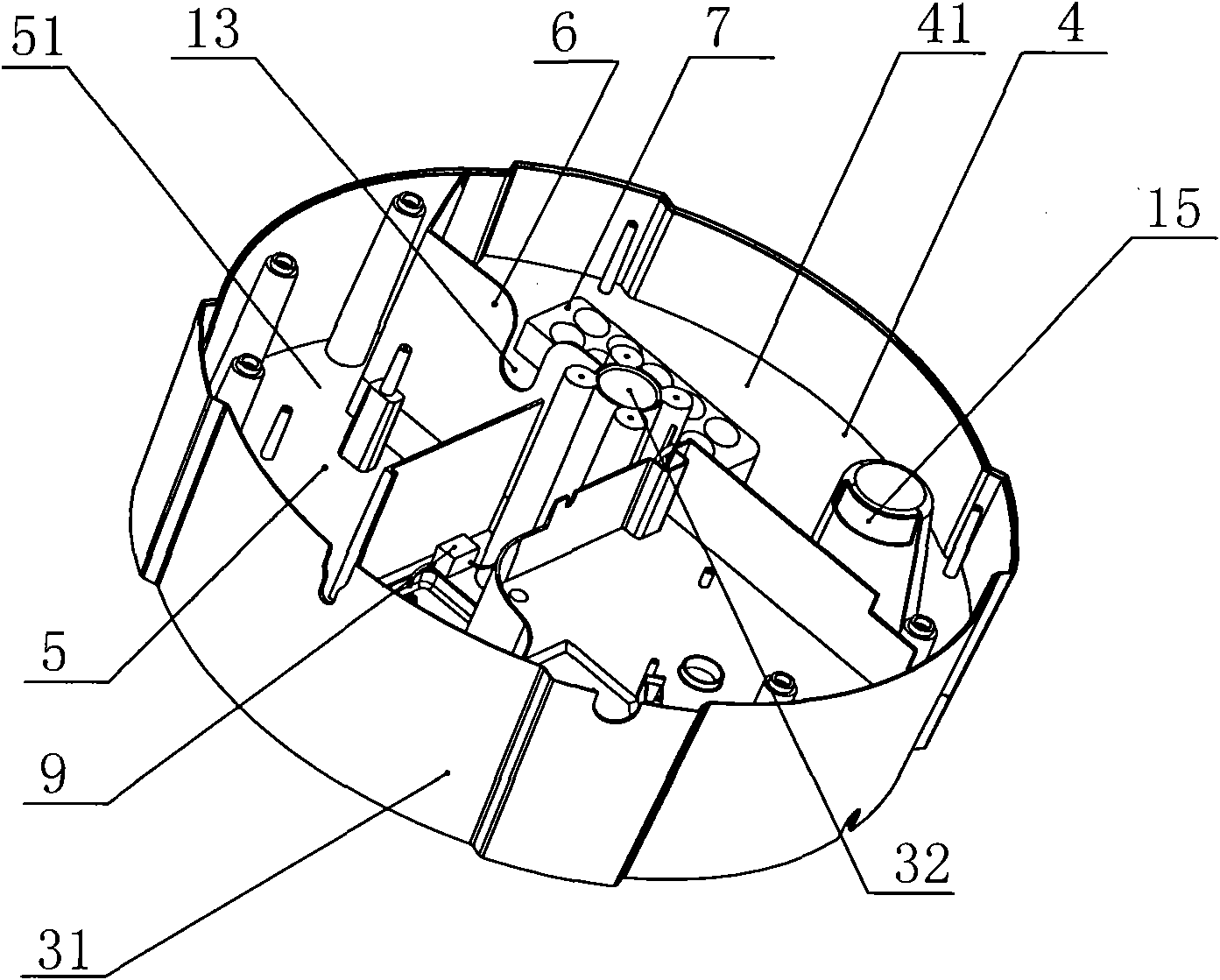

[0039] Such as figure 2 and image 3As shown, the base 3 includes a basin-shaped integral bottom chamber 31 made of plastic injection molding, and the bottom chamber 31 is provided with an atomization chamber 4 and a...

Embodiment 2

[0053] Such as Figure 9 As shown, the humidifying fan includes a fan head 1, a support column 2 of the fan head and a base 3, the support column 2 is supported on the base 3; the base 3 is provided with an atomizing chamber 4 distributed up and down and a water storage chamber 5, wherein the atomization chamber 4 is located above the water storage chamber 5, the atomization chamber 4 and the water storage chamber 5 are separated by a partition wall 6, and the atomization chamber 4 is provided with Ultrasonic nebulizer 7, the base 3 is also provided with a pressurized fan 8 to increase the air pressure in the atomization chamber 4 and can replenish the water in the water storage chamber 5 to the atomization chamber 4 The water supply pump 9 inside, the atomization chamber top cover 41 of the atomization chamber 4 has a mist outlet, one port of the delivery pipe 16 communicates with the mist outlet 10, and the other port extends to the fan head 1 front position.

[0054] Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com