Fan impeller for cooling

A fan impeller and blade technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as restricting the application of large-diameter impellers, customer installation, inconvenient maintenance, and limited bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

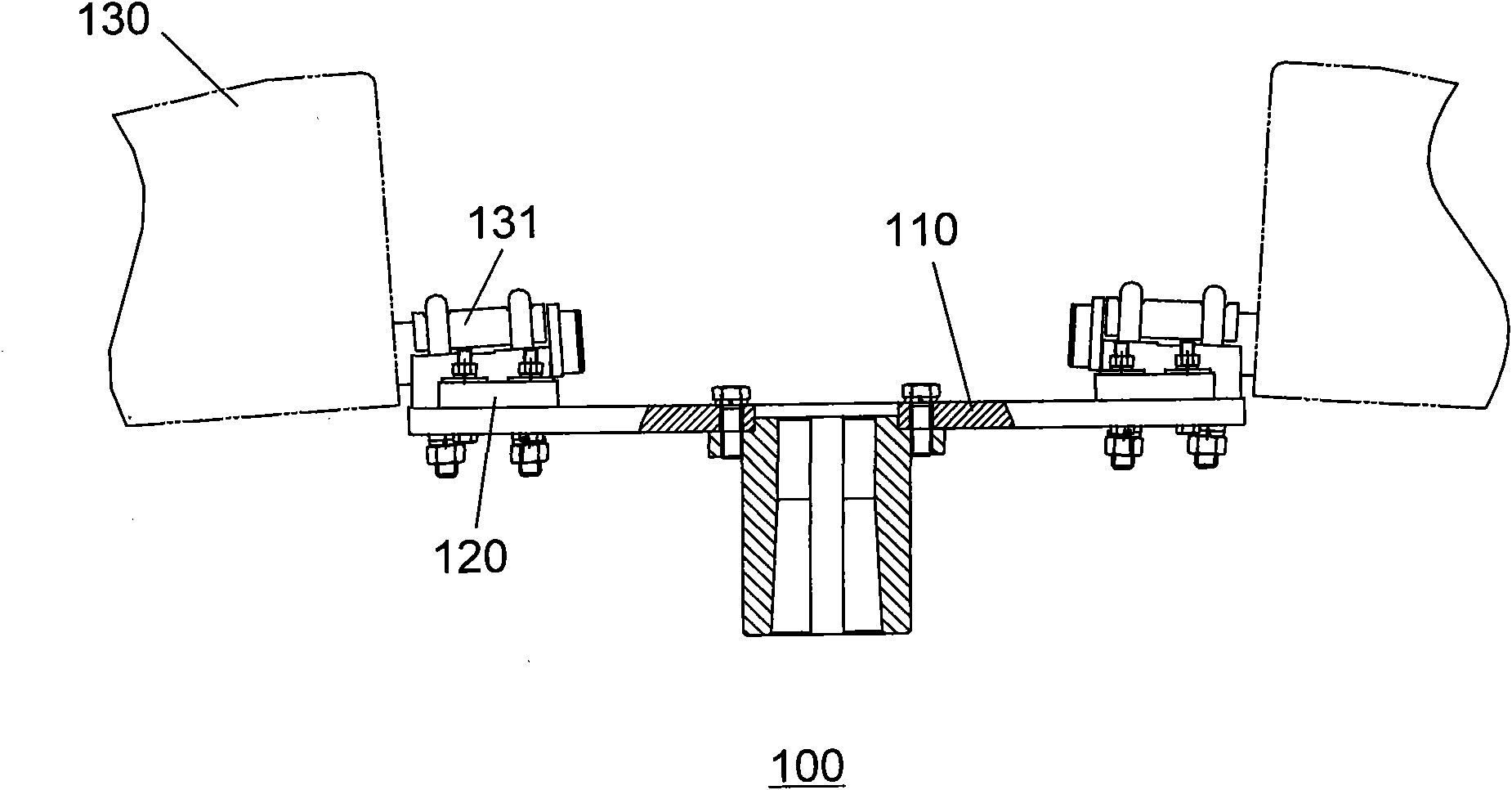

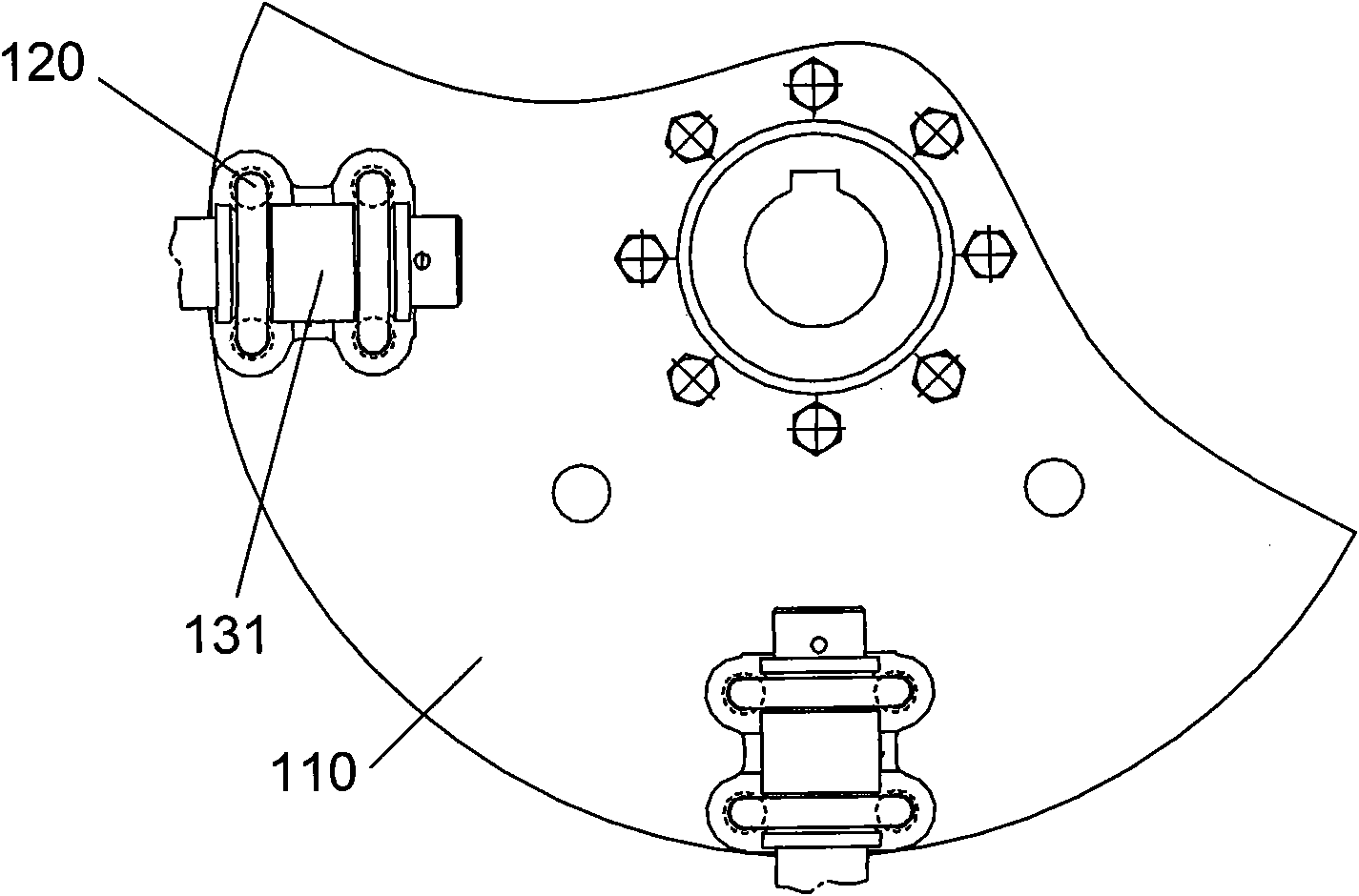

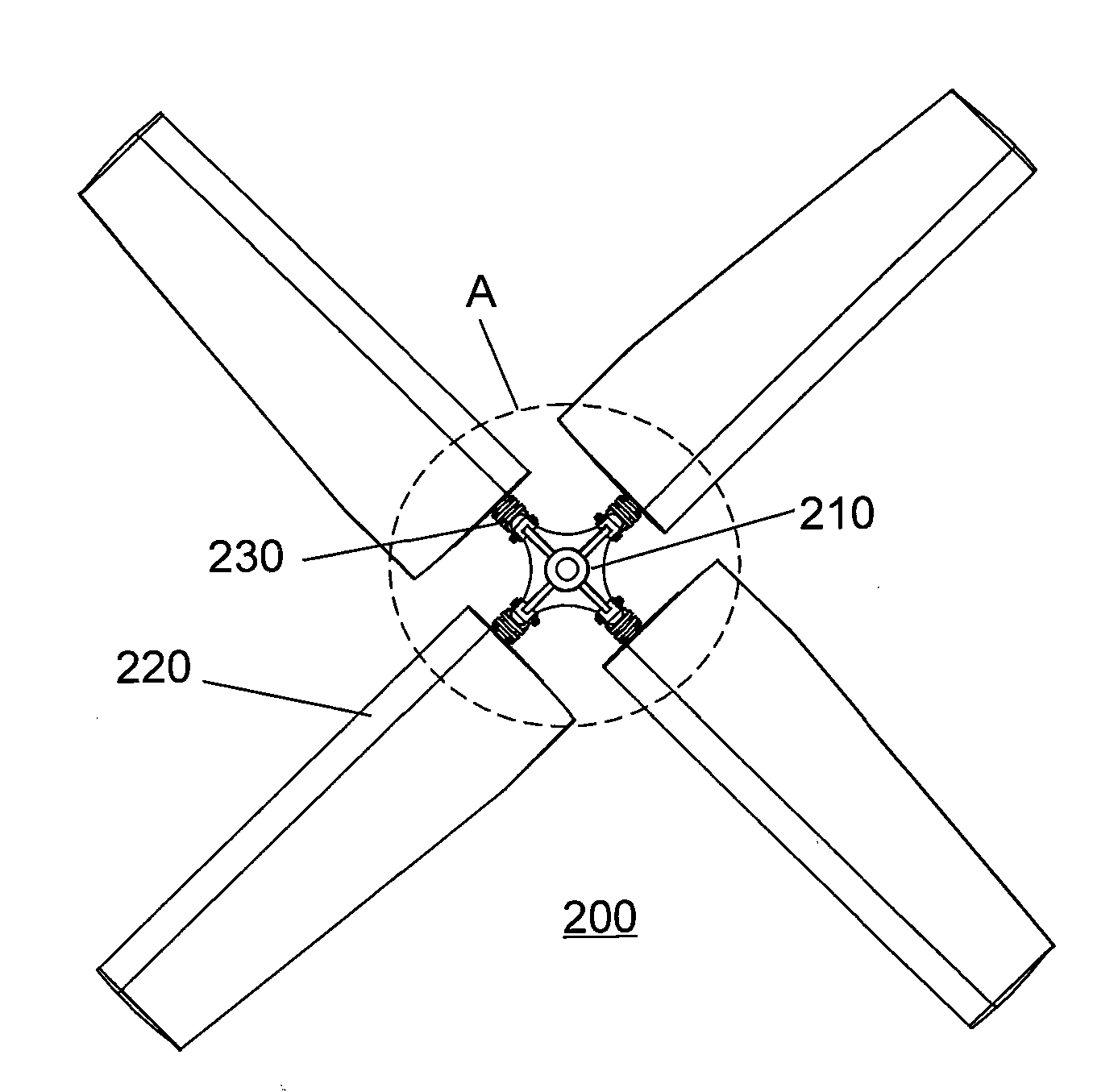

[0017] Please combine Figure 3 ~ Figure 5 As shown, the cooling fan impeller 200 of the present invention includes a hub 210 and several blades 220. Taking four blades 220 as an example, four blade mounts 230 are uniformly arranged around the hub 210, and the petiole 221 of each blade 220 A swing connection part 240 is provided, and is connected to the corresponding blade installation seat 230 through the swing connection part 240 . Specifically, the body of the hub 210 has a cross-shaped structure, and ribs 211 are provided on the edge; each blade mounting seat 230 has a cylindrical structure, which is connected and fixed with the hub 210 in the radial direction, and has a pin hole in the axial direction. The end of the petiole 221 of each blade 220 is provided with a flange 222, and each swing connecting part 240 then incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com