Device and method for on-line monitoring of transient-state low-cycle fatigue life loss of pressure-containing member outside boiler

A pressure-bearing component, low-cycle fatigue technology, applied in program control, control system, computer control and other directions, can solve the problems of shortening the service life of the pressure-bearing components outside the boiler of the power station, uneven temperature distribution, high cost and other problems, to ensure The effect of long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

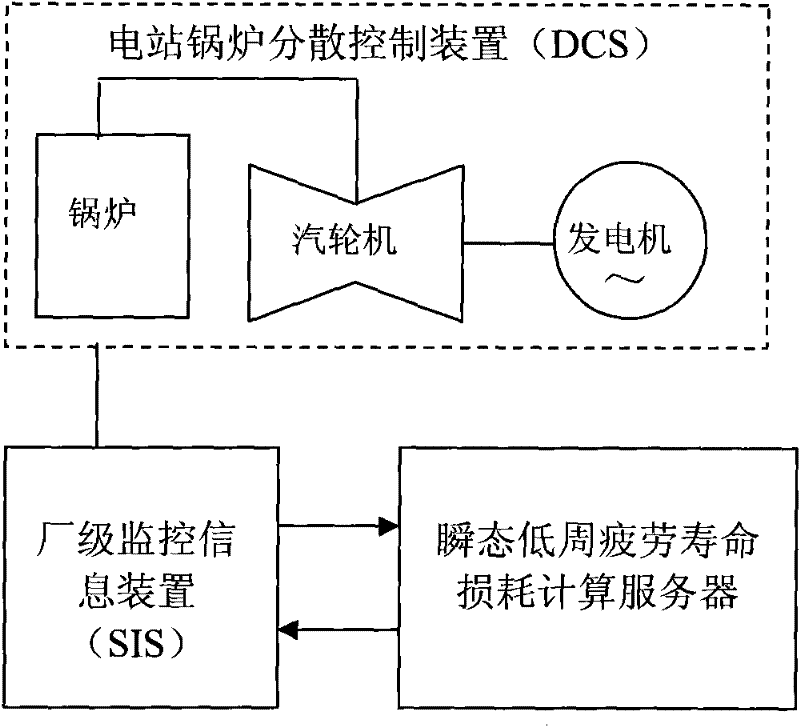

[0039] Such as figure 1 As shown, it is a block diagram of the online monitoring device for transient low-cycle fatigue life loss of pressure-bearing parts outside the furnace according to the present invention. The online monitoring device for transient low-cycle fatigue life loss of pressure-bearing parts outside the furnace consists of It consists of a computing server and computer software running on it, a plant-level monitoring information device, and a distributed control device for power plant boilers. The transient low-cycle fatigue life loss calculation server is connected to the power station boiler distributed control device through the plant-level monitoring information device.

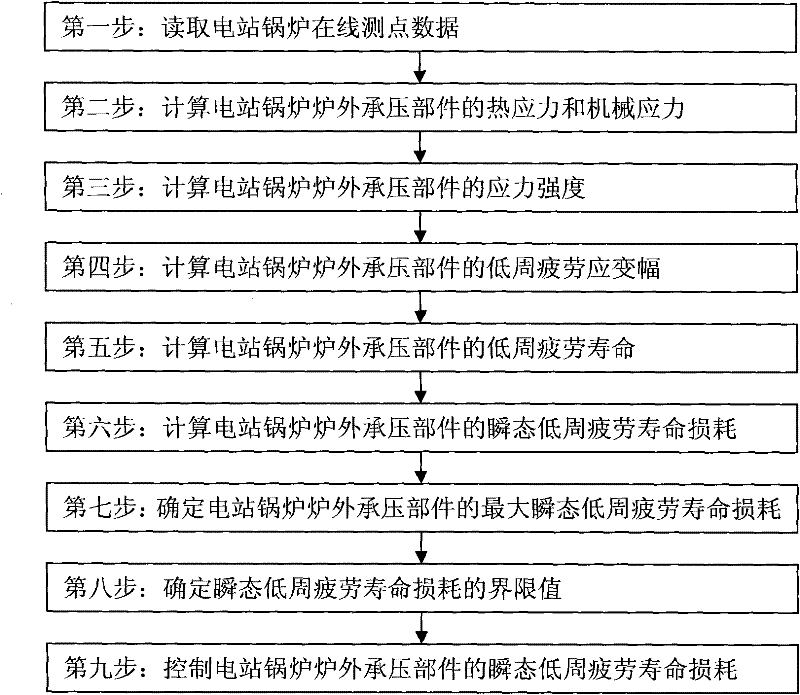

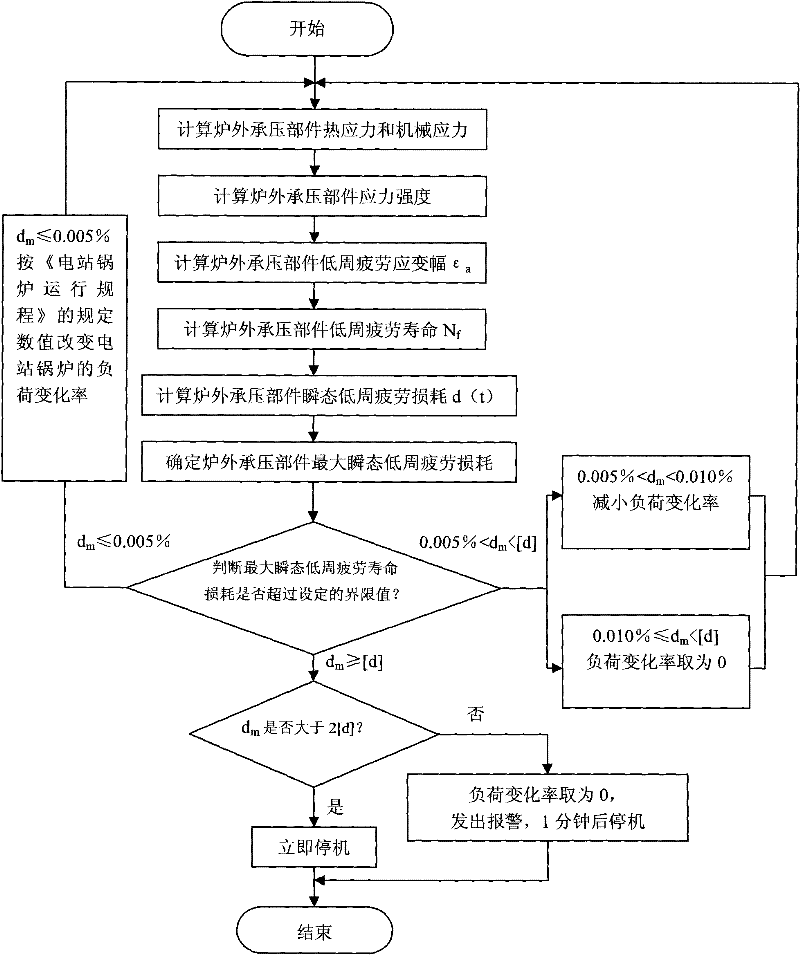

[0040] Such as figure 2 As shown, it is a flow chart of the online monitoring method for transient low-cycle fatigue life loss of the pressure-bearing parts outside the furnace of the present invention, such as image 3 As shown, it is a block diagram of the computer software adopted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com