Welder for rolling facility, rolling facility, and rolling method

一种轧制设备、焊机的技术,应用在轧制设备用焊机领域,能够解决未能提示最佳方式、没有明示也考虑到、阻碍生产率等问题,达到设备费用减少、时间短、生产效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

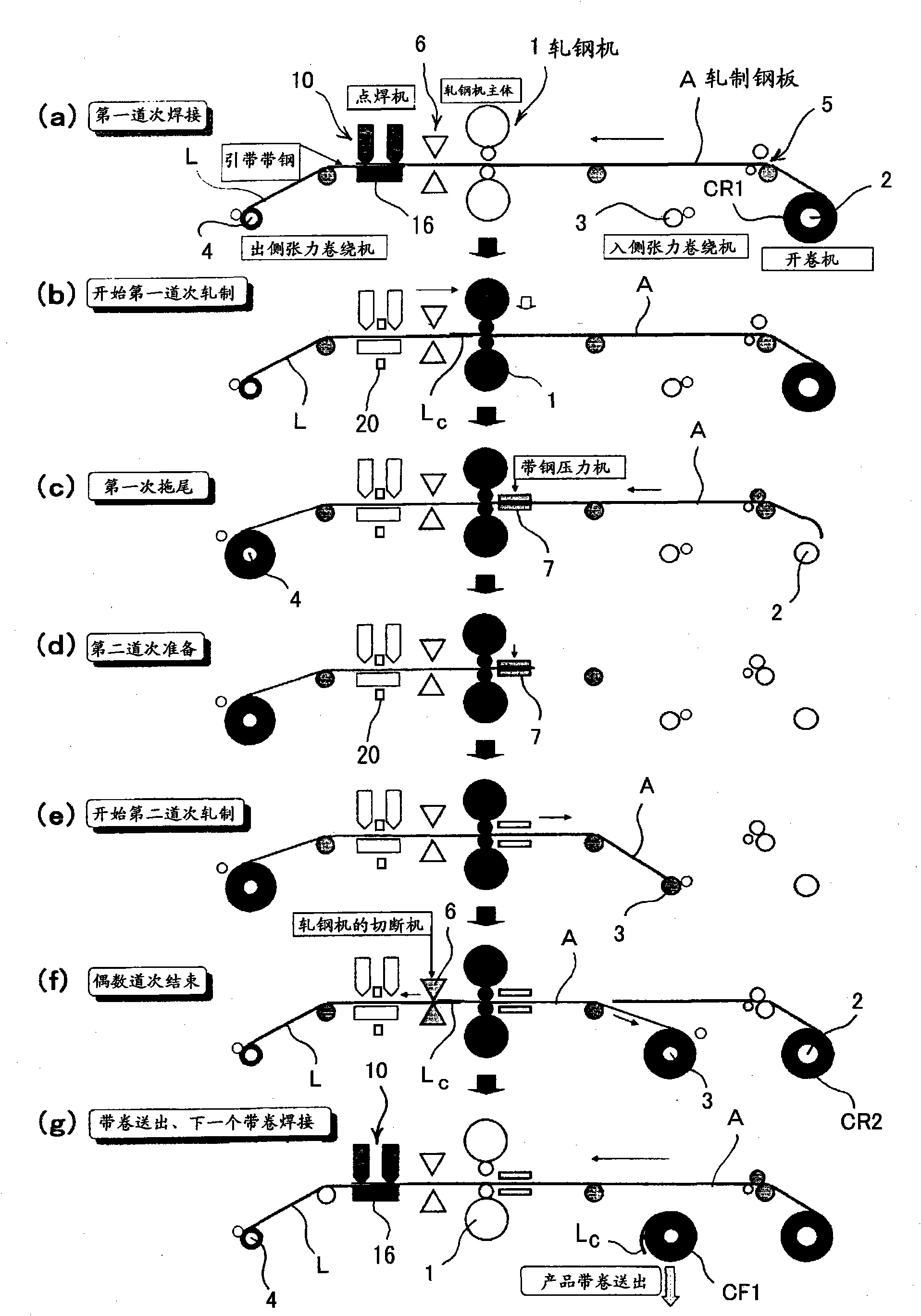

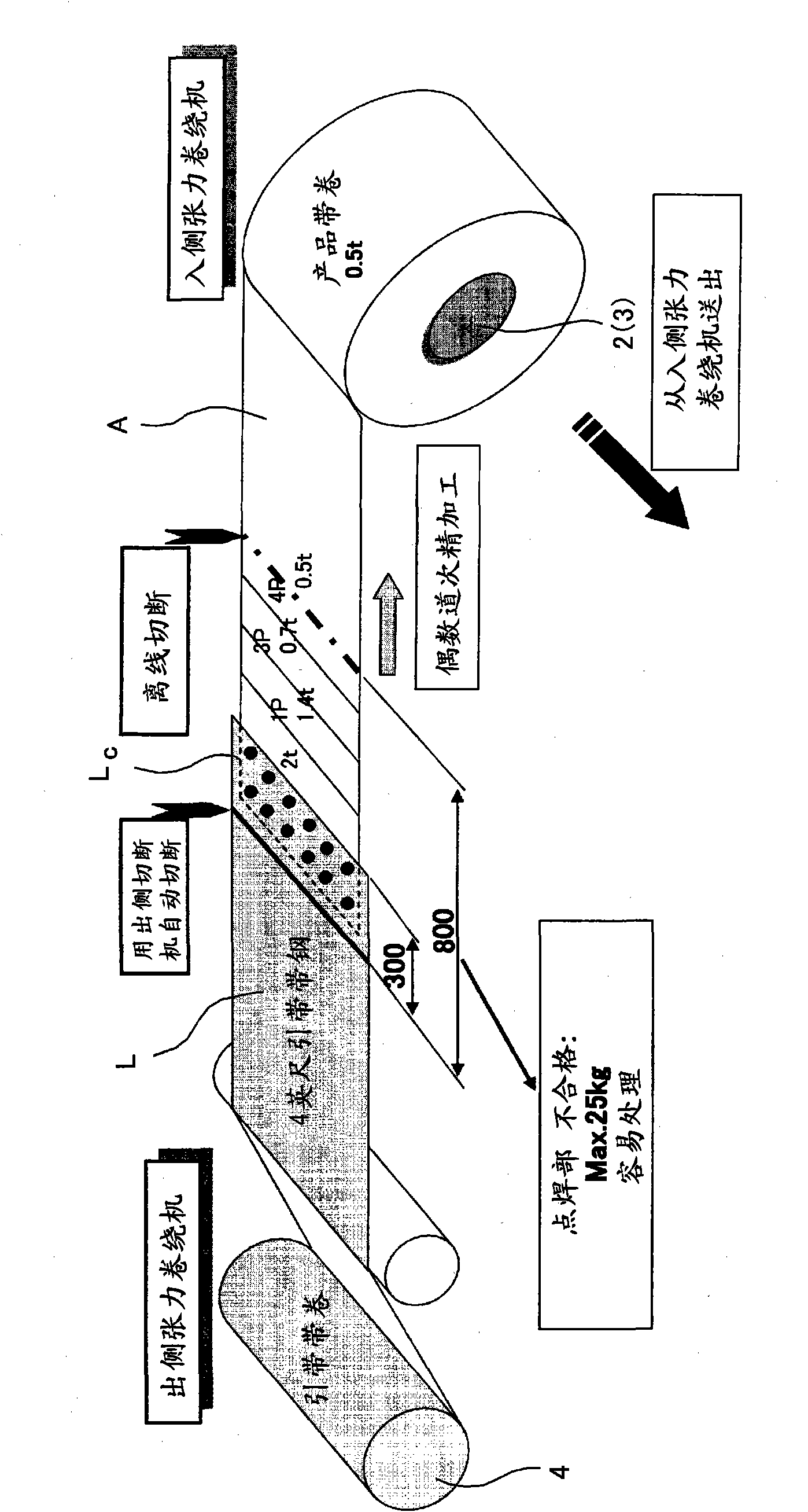

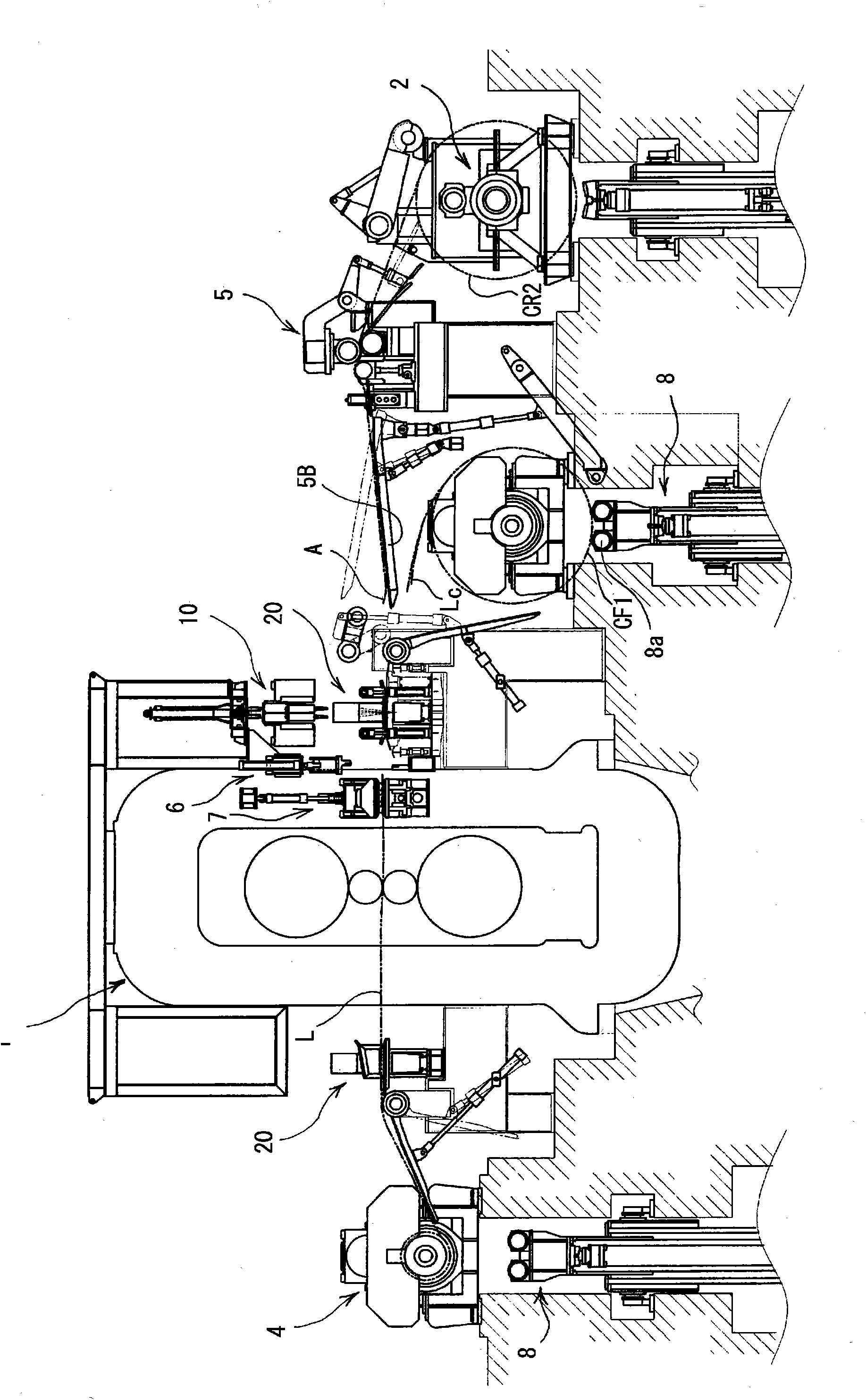

[0065] Figure 1 to Figure 11 The rolling method and rolling facility related to the reversing cold rolling of ordinary steel which show one embodiment of this invention. figure 1 is a diagram conceptually showing a rolling method and a rolling facility according to an embodiment of the present invention, figure 2 is a diagram showing the basic concept of important parts in this rolling method, image 3 It is a figure which exemplifies the overall view of a rolling facility. Figure 4 ~ Figure 7 It is a detailed diagram showing the structure of the welder 10 and its surroundings in the rolling facility, Figure 8 It is a perspective view showing the welding machine 10 and the like together with the rolling mill 1 . also, Figure 9 ~ Figure 11 It is a figure explaining the effect of the rolling method and rolling facility shown in figure.

[0066] Such as figure 1 As shown, in the illustrated equipment, there are rolling mill (rolling mill main body) 1, uncoiler (uncoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com