Automatic welding manipulator

An automatic welding and manipulator technology, applied in the field of manipulators, can solve the problems of excessive exposure, high labor cost, visual impairment, etc., and achieve the effect of improving work efficiency, improving welding quality, and easy control of speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

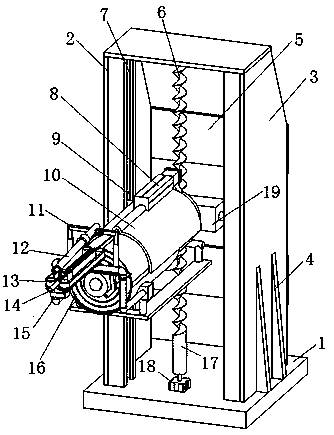

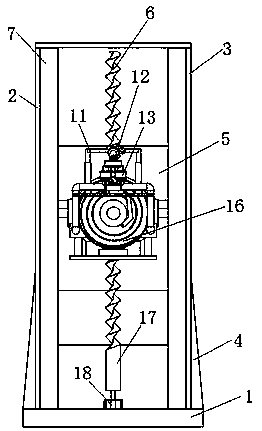

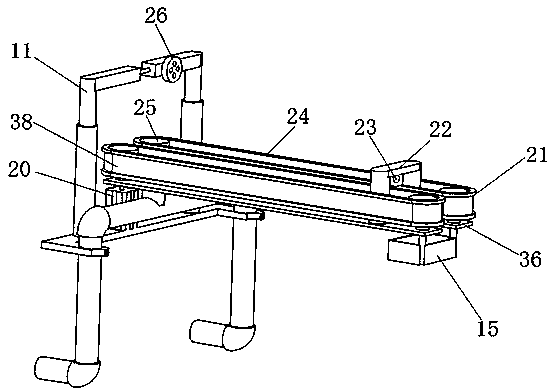

[0026] Embodiment: automatic welding manipulator, constitutes as Figure 1-6 Shown, comprise frame base 1, frame left vertical plate 2 and frame right vertical plate 3 are arranged in parallel on frame base 1, frame base 1, frame left vertical plate 2 and frame right vertical plate 3 all Be stainless steel material, be provided with elevating mechanism 6 between frame left vertical plate 2 and frame right vertical plate 3, elevating mechanism 6 is connected with storehouse body rear seat 27, storehouse body rear seat 27 top is provided with cylinder 8, and cylinder 8 The output end is connected to the top cover 10, and the rear seat 27 of the warehouse body is provided with a welding rod storage bin 16 in front, and the inside of the welding rod storage bin 16 is provided with a clockwork coil 31, and the periphery of the clockwork coil 31 is provided with a circular track 33, and the inside of the clockwork coil 31 is provided with Clockwork 37, clockwork coil 31 outside is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com