Tractor support beam structure on elevator

A technology for supporting beams and traction machines. It is used in elevators, transportation, and packaging in buildings. It can solve the problems of vibration and inward turning of traction machines, eliminate the possibility, and ensure normal operation and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

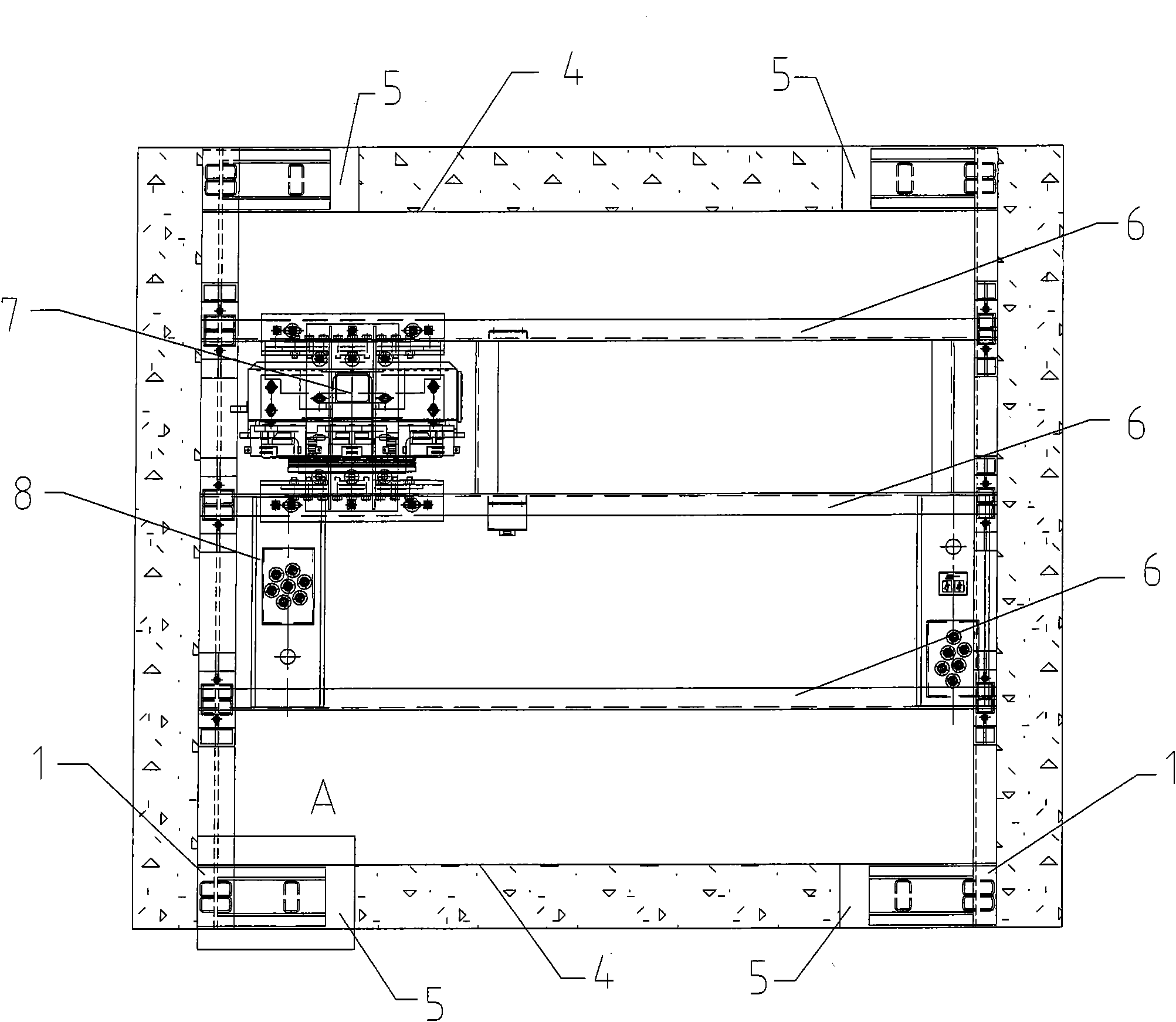

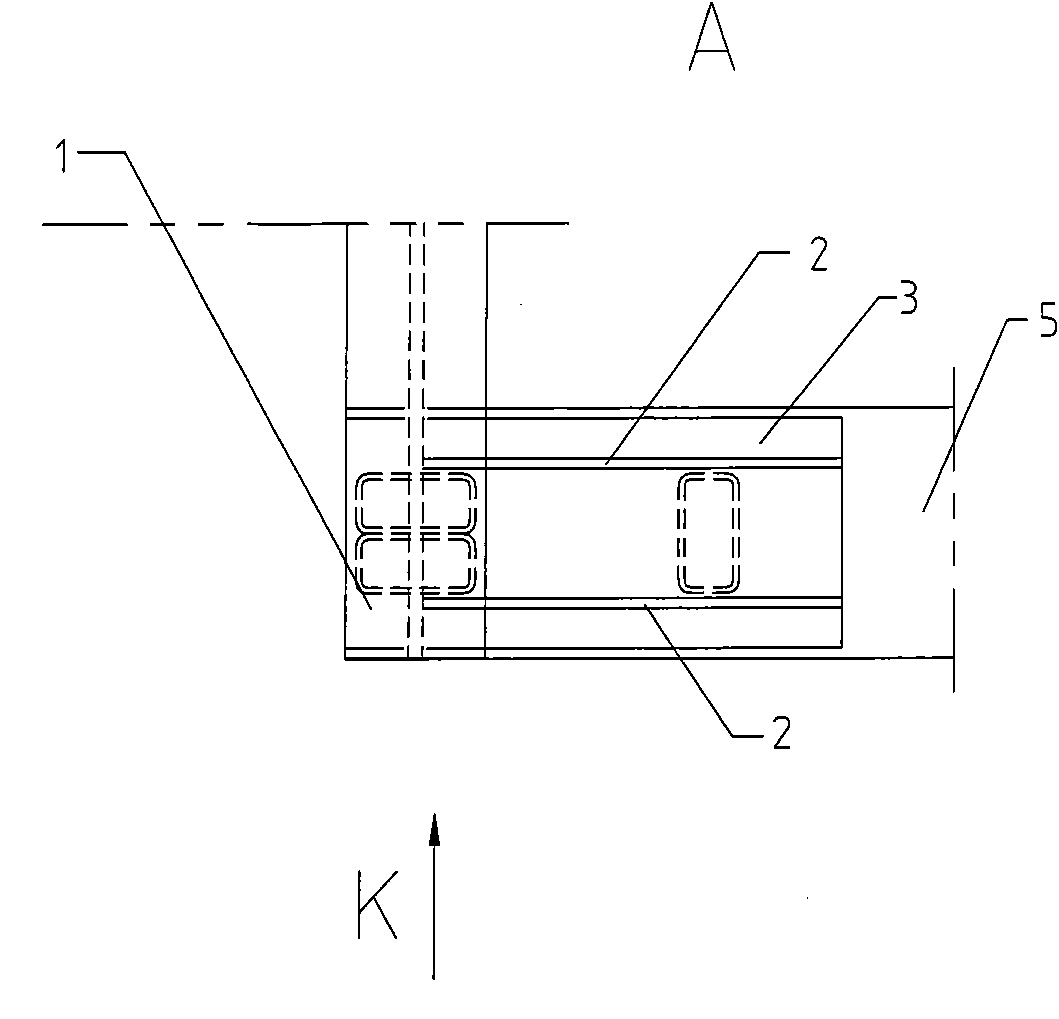

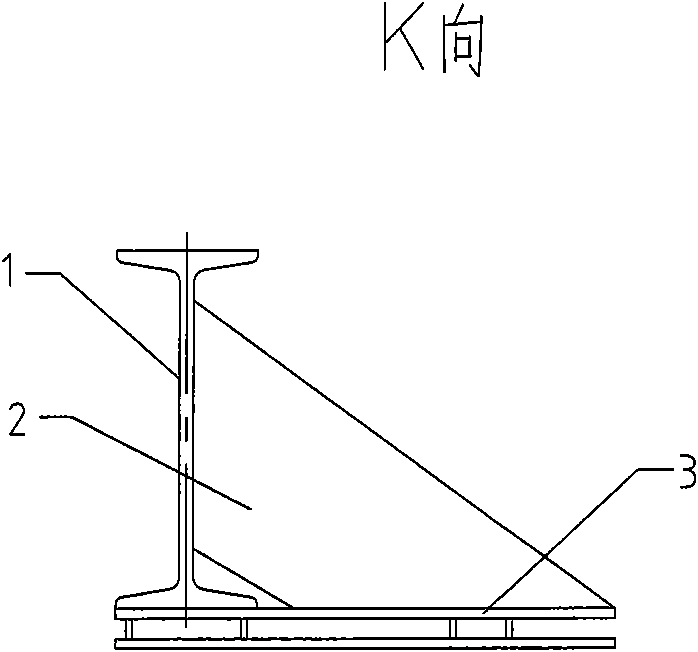

[0011] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] see Figure 1-3 As shown, the supporting beam structure of the traction machine on the elevator includes a supporting beam 1, and there are two supporting beams 1, which are arranged in parallel and spaced apart. Two pairs of shelving holes 5 oppositely arranged are opened on the inner wall 4 of the hoistway, as shown in FIG. figure 1 As shown, the two ends of each support beam 1 are respectively fixedly extended in the shelving holes 5, and a plurality of spaced shelving beams 6 are vertically arranged on the two support beams 1, and two adjacent shelving beams 6 are arranged vertically on the two support beams 1. The traction machine 7 is carried on the machine beam 6, and the rope head assembly fixing seat 8 for fixing the steel wire rope is carried on another group of adjacent two machine beams 6, and the supporting beam 1 carries the tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com