Nonmetallic anti-explosion container and manufacturing process thereof

A manufacturing process and non-metallic technology, which is applied in the field of non-metallic explosion-proof containers and their manufacturing processes, can solve the problems of large volume, heavy weight, and lack of mobility of explosion-proof containers, achieve weight reduction, explosion shock wave attenuation, and improve product protection capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

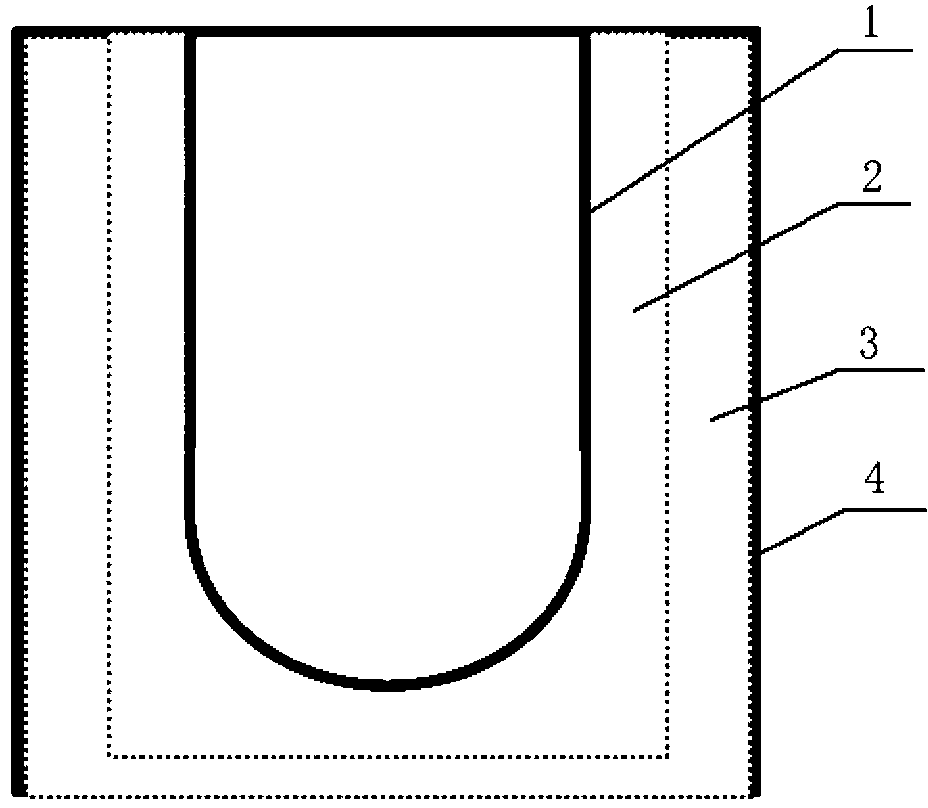

[0024] Such as figure 1 As shown, a non-metallic explosion-proof container provided by the present invention is composed of four main parts: an inner protective layer 1, an energy-absorbing layer 2, a main protective layer 3, and an outer decorative layer 4.

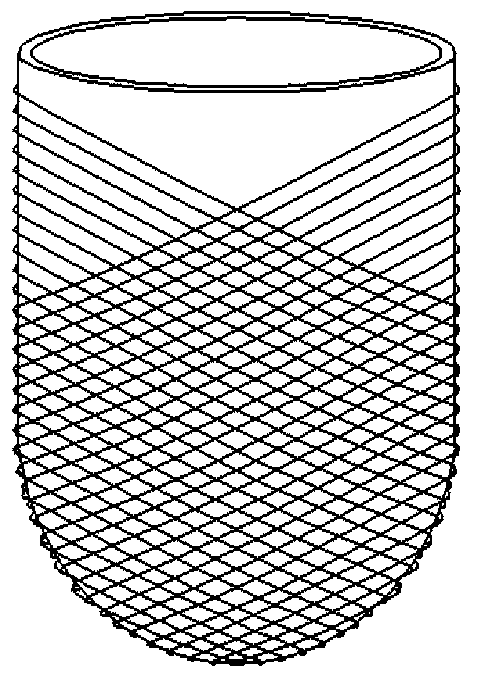

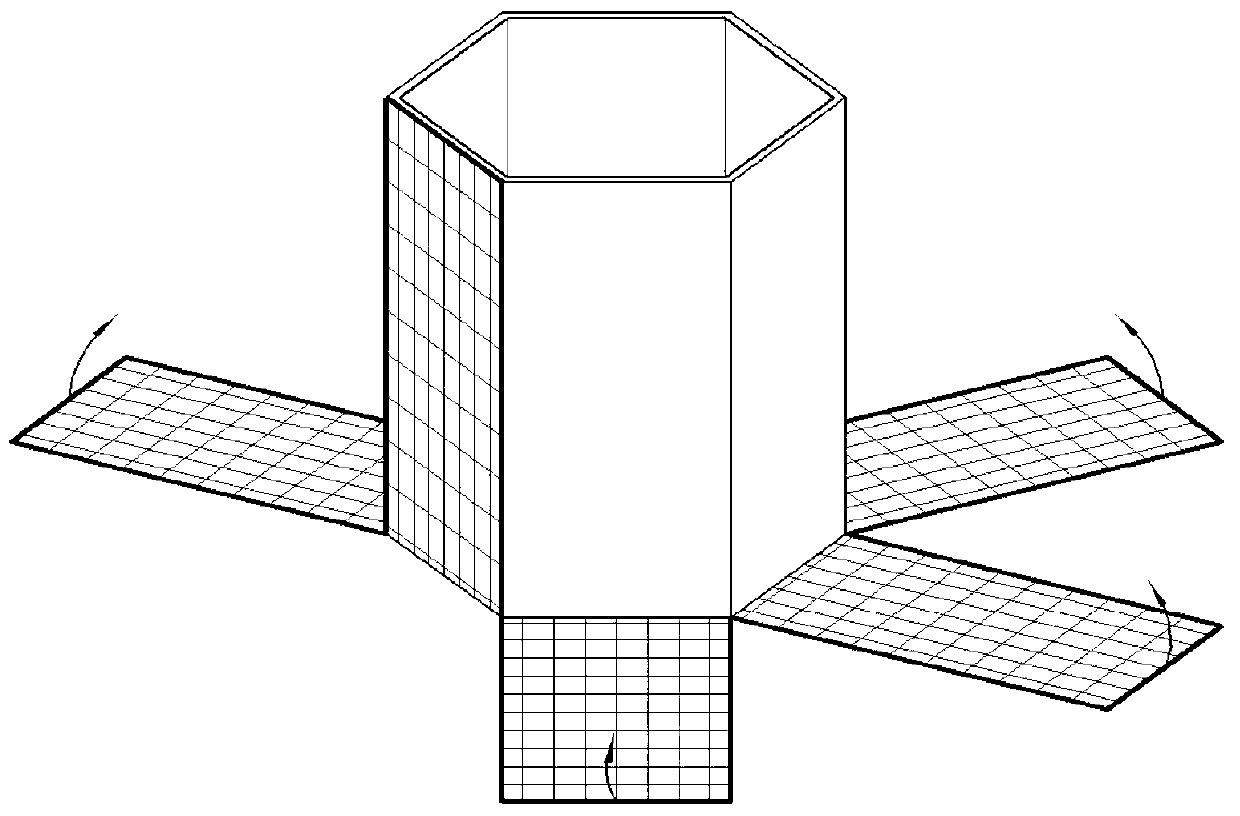

[0025] The inner protective layer is made of high-strength fiber material and adhesive material, which has strong explosion-proof ability and good crushing and energy-absorbing effect. Such as figure 2 As shown, during the production process, high-strength fibers are wound and bonded layer by layer around the capsule-shaped mold to form a high-strength and high-hardness semi-capsule-shaped inner protective layer. This structure and process can give full play to the tensile properties of high-strength fiber materials, and effectively unload and attenuate the spherical shock wave generated by the explosion.

[0026] The energy-absorbing layer is filled with polymer porous material to absorb the explosion energy. This k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com