Bistable state magnetic latching contactor for power supply switch of electric tricycle

An electric tricycle, power switch technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of switch contact pressure drop, unreliable switch contact, increased heating resistance, etc., to improve reliability and improve The effect of switch contact quality and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0027] A preferred embodiment is given below:

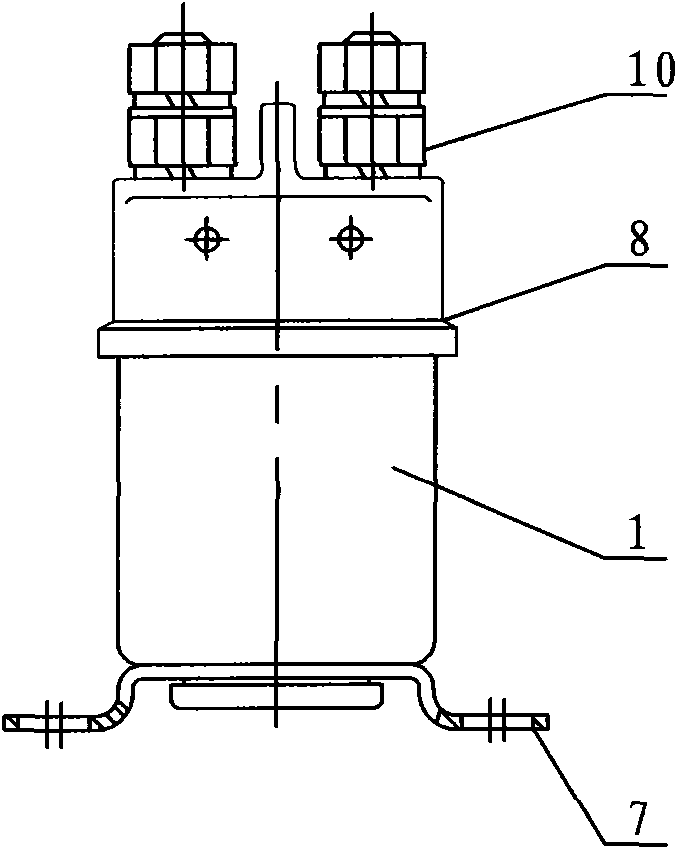

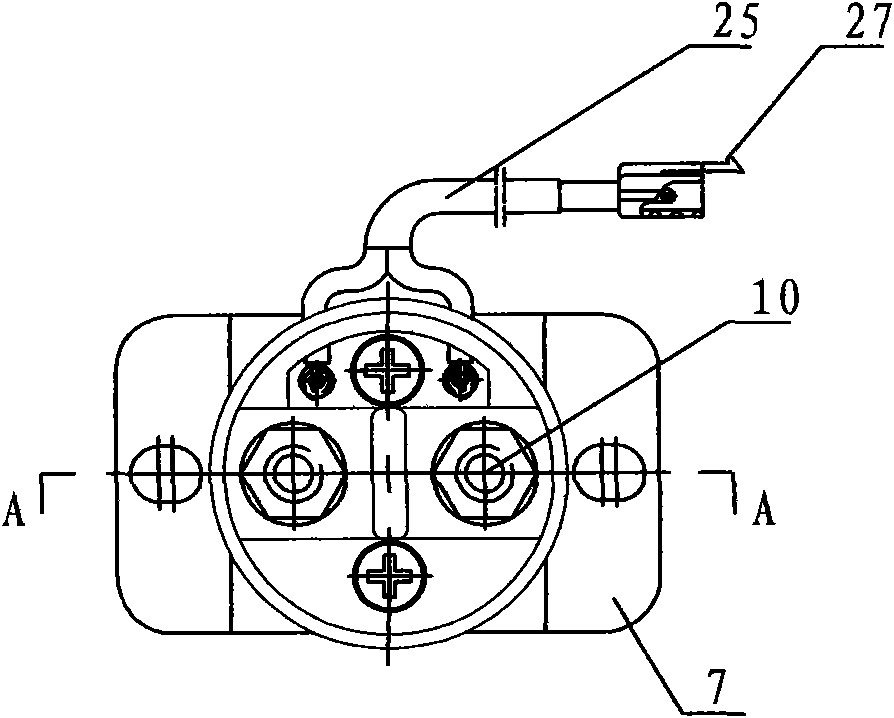

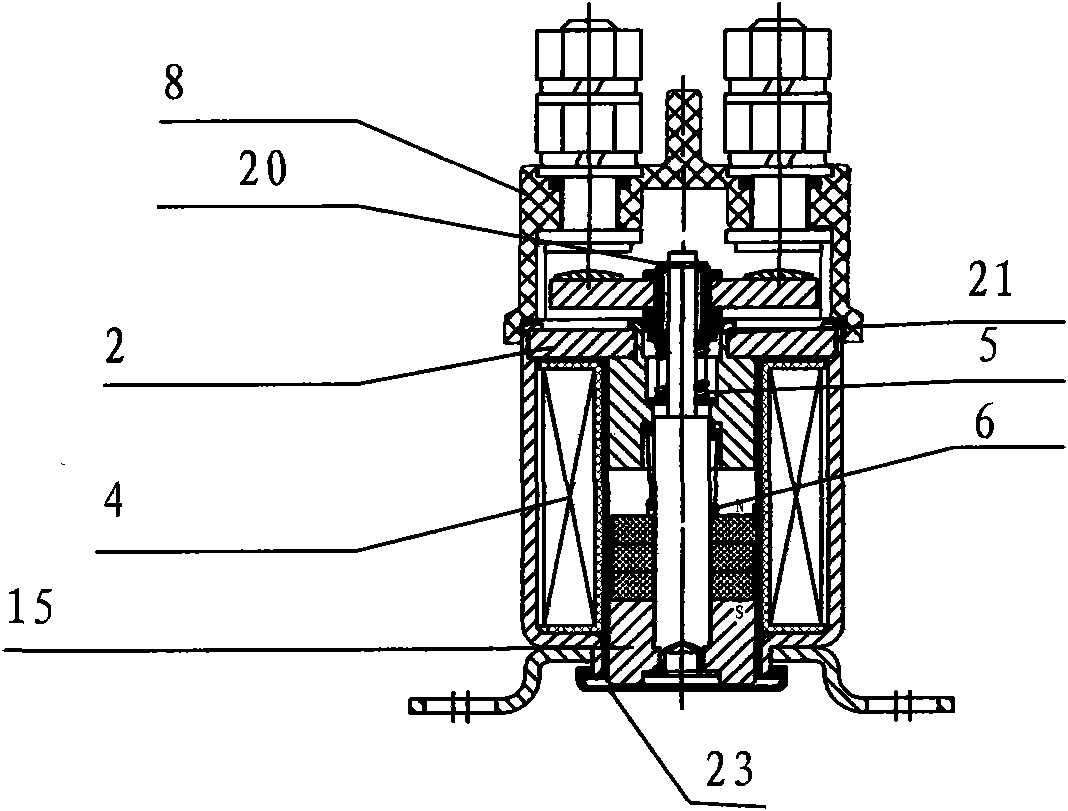

[0028] Such as Figures 1 to 8 As shown, a bistable magnetic holding contactor for a power switch of an electric tricycle includes a cover assembly, the lower part of the cover assembly is connected to the shell 1, and the upper part of the shell 1 is fixed with a static iron core 2, and the static iron core 2 A moving iron core assembly is connected below, a moving contact assembly is connected above the static iron core 2, a copper sleeve 3 is arranged outside the static iron core 2, and a coil is arranged between the copper sleeve 3 and the shell 1 Assembly 4, an upper spring 5 is arranged between the static iron core 2 and the moving contact assembly, and a lower spring 6 is arranged between the static iron core 2 and the moving iron core asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com