Sewing machine

A sewing machine and support mechanism technology, applied in the field of sewing machines, can solve problems such as difficulty in adjusting oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

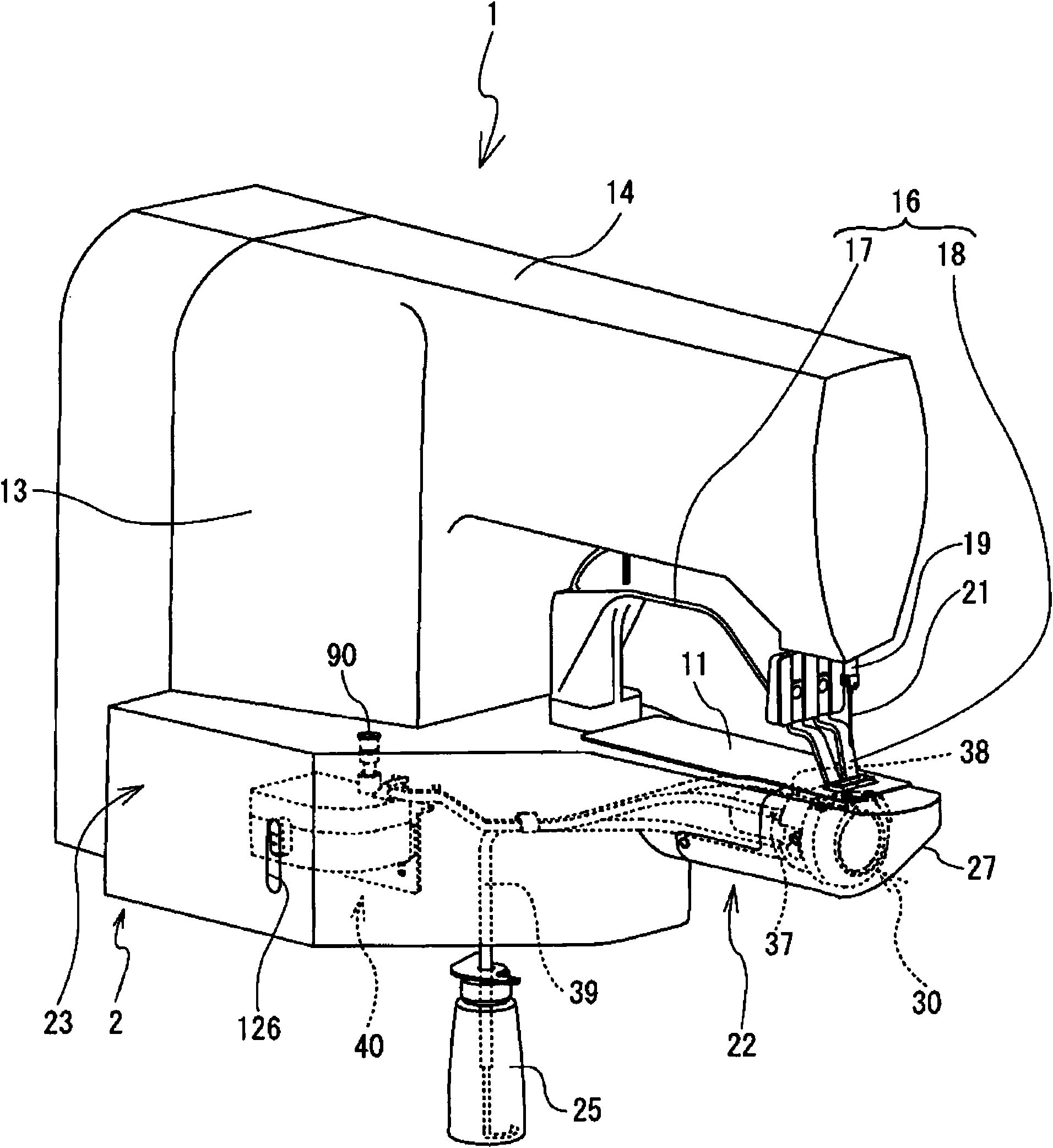

[0041] Next, a sewing machine 1 according to an embodiment of the present invention will be described with reference to the drawings. refer to figure 1 , the structure of the sewing machine 1 will be described. Will figure 1 Right obliquely lower, left obliquely upper, right obliquely upper, left obliquely lower as the front, rear, right and left of the sewing machine 1 respectively.

[0042]The sewing machine 1 includes a base 2 , a substantially square pillar-shaped column portion 13 , and a substantially square pillar-shaped machine arm portion 14 . The column portion 13 extends upward from the rear of the base 2 . The arm portion 14 extends forward from the upper portion of the column portion 13 . The arm part 14 includes a needle bar 19 in its lower part. The needle bar 19 is driven to reciprocate up and down by a motor (not shown). The needle bar 19 includes a needle 21 at its lower end. A thread spool (not shown) supplies the upper thread to the needle 21 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com