110V passive high-power factor circuit

A power factor correction, high power technology, applied in the field of 110V passive high power factor circuits, can solve the problems of high power consumption of the whole lamp and low power factor of PPFC circuits, and achieves improved power factor, reduced current harmonics, and improved switching. effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

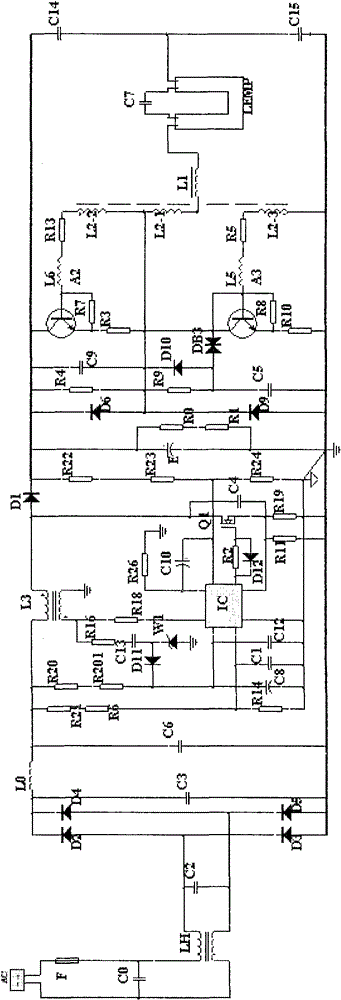

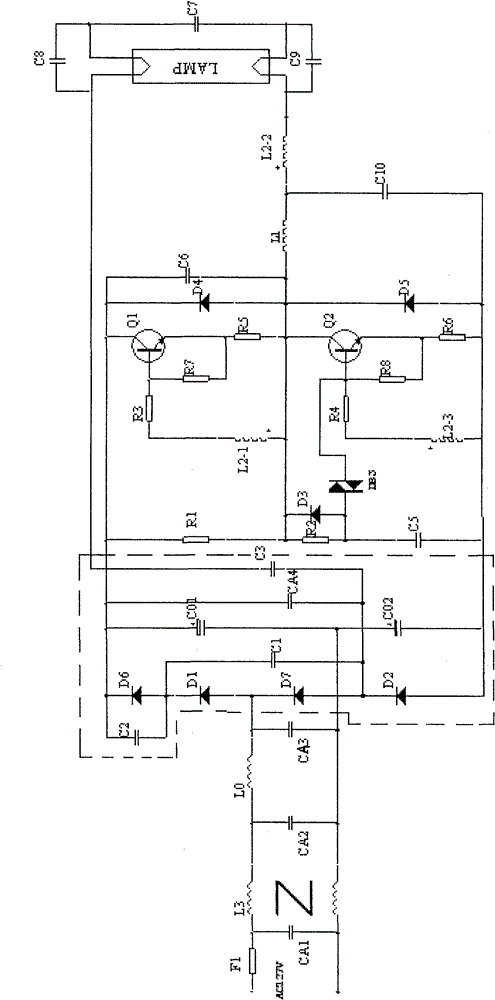

[0022] Example: such as figure 2 As shown, the 110V passive high power factor circuit includes an EMC circuit, a half-bridge circuit, a series resonant circuit and a load. It is composed of inductance L2-2 and capacitor C7. Its function is to generate the starting high voltage required by the lamp; the input ends of the EMC circuit are connected to the input ends of the power supply, and power factor correction is connected between the EMC circuit and the half-bridge circuit. circuit, the power factor correction circuit includes a diode D2, a diode D7, a diode D1, a diode D6, an electrolytic capacitor CO1, and an electrolytic capacitor CO2, wherein the diode D2, the diode D7, the diode D1, and the diode D6 are sequentially connected in series, and the electrolytic capacitor CO1 Connect the diode D2, diode D7, diode D1, and diode D6 in series with the electrolytic capacitor CO2, connect the negative pole of the electrolytic capacitor CO1 to the positive pole of the electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com