Variable-gap roll shaft fruit and vegetable classifier

A classifier and roller technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low classification accuracy and rigid gap change process, and achieve high classification accuracy, stable change process and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

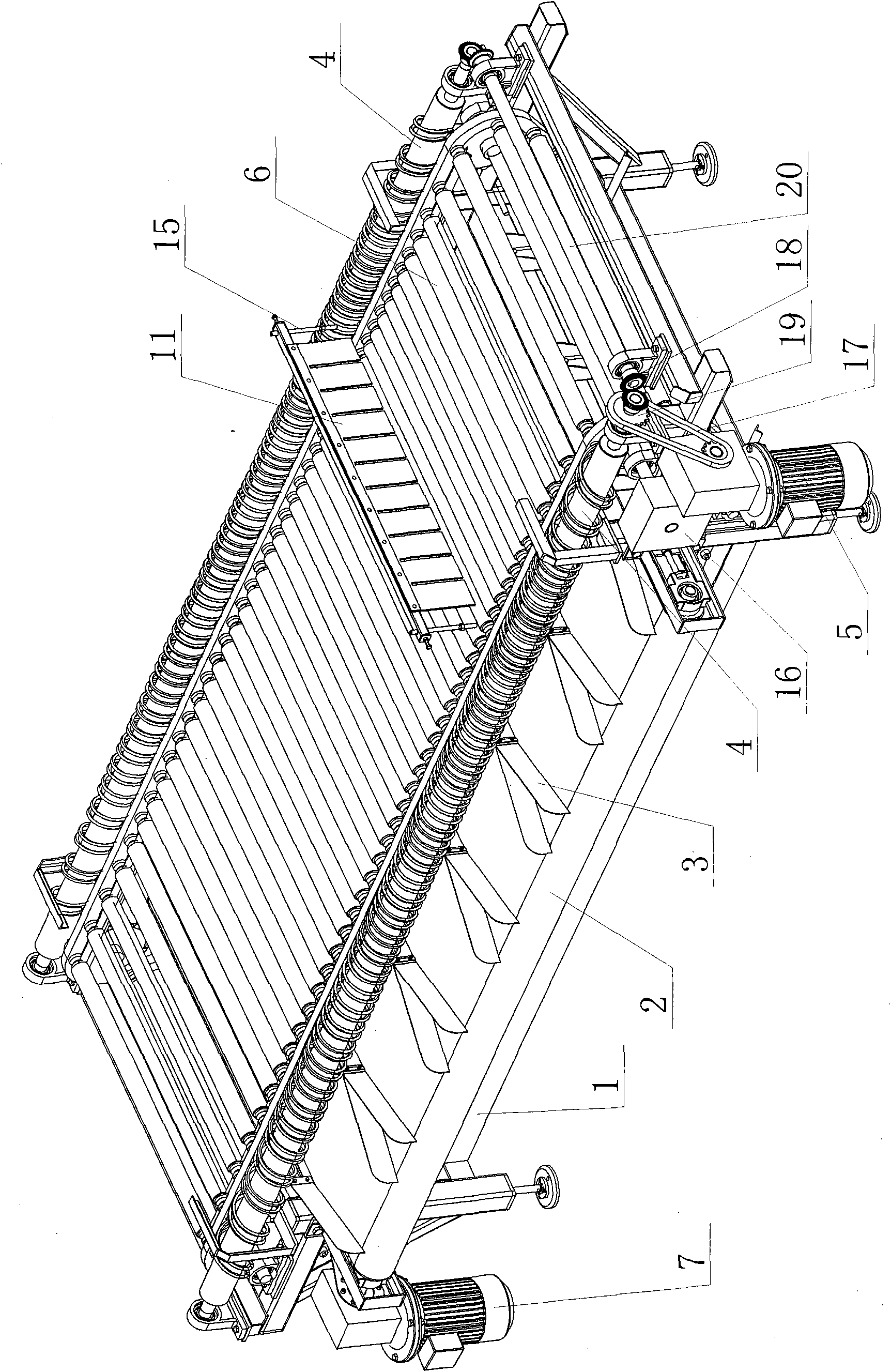

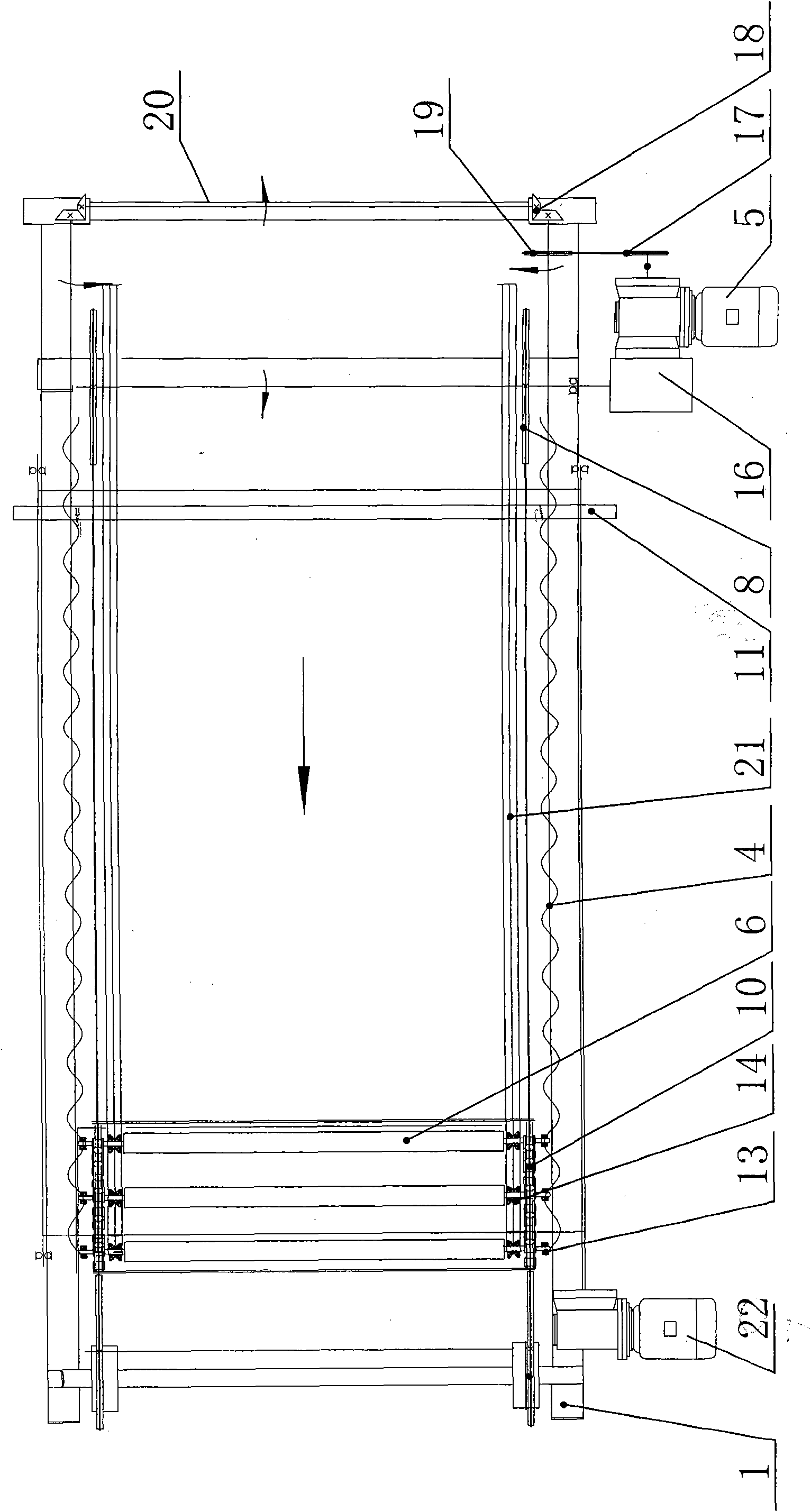

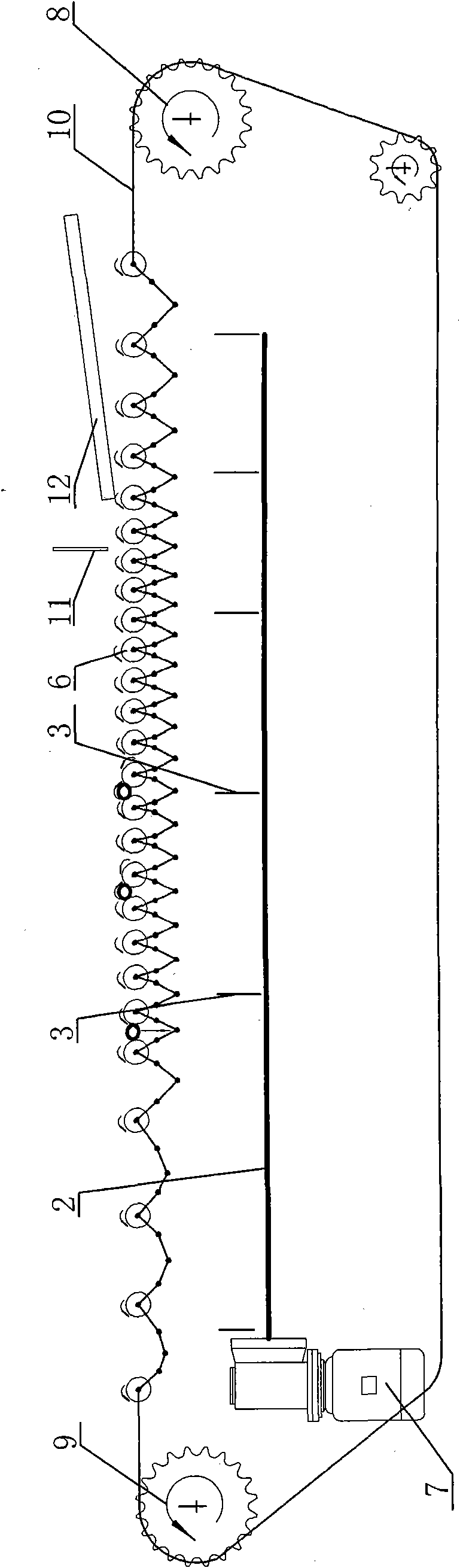

[0020] A variable gap roller type fruit and vegetable grader, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the driving sprocket 8 installed on the frame 1 through the bearing seat, the driving sprocket 8 drives the driven sprocket 9 to rotate through the chain 10, and the cylindrical grading rollers 6 are evenly distributed horizontally on the chain 9, so that the upper layer The roller surfaces of cylindrical grading rollers uniformly distributed on the chain form a plane grading bed, and a flat belt conveyor 2 is arranged below the plane grading bed, and the grading rollers outside the chain 10 are located at both ends of each cylindrical grading roller. Propelling rollers 14 are installed on the top respectively, and guide rollers 13 matched with horizontal guide rails 21 are fixed on the grading roller shafts located inside the chain 10. On the vertical sides of the frame 1, parallel bearings with variable speed are installed respectively through bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com