Omnidirectional spherical roller caster

a spherical roller caster and caster technology, applied in the direction of roller skates, skateboards, sport apparatus, etc., can solve the problems of jerky, inconvenient initial movement of the load, energy-intensive initial motion of the load, etc., and achieve the initial improper alignment of the heavy load on the caster to the desired direction of movement. , the loss of energy, and the inability to accurately adjust the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example two

B. EXAMPLE TWO

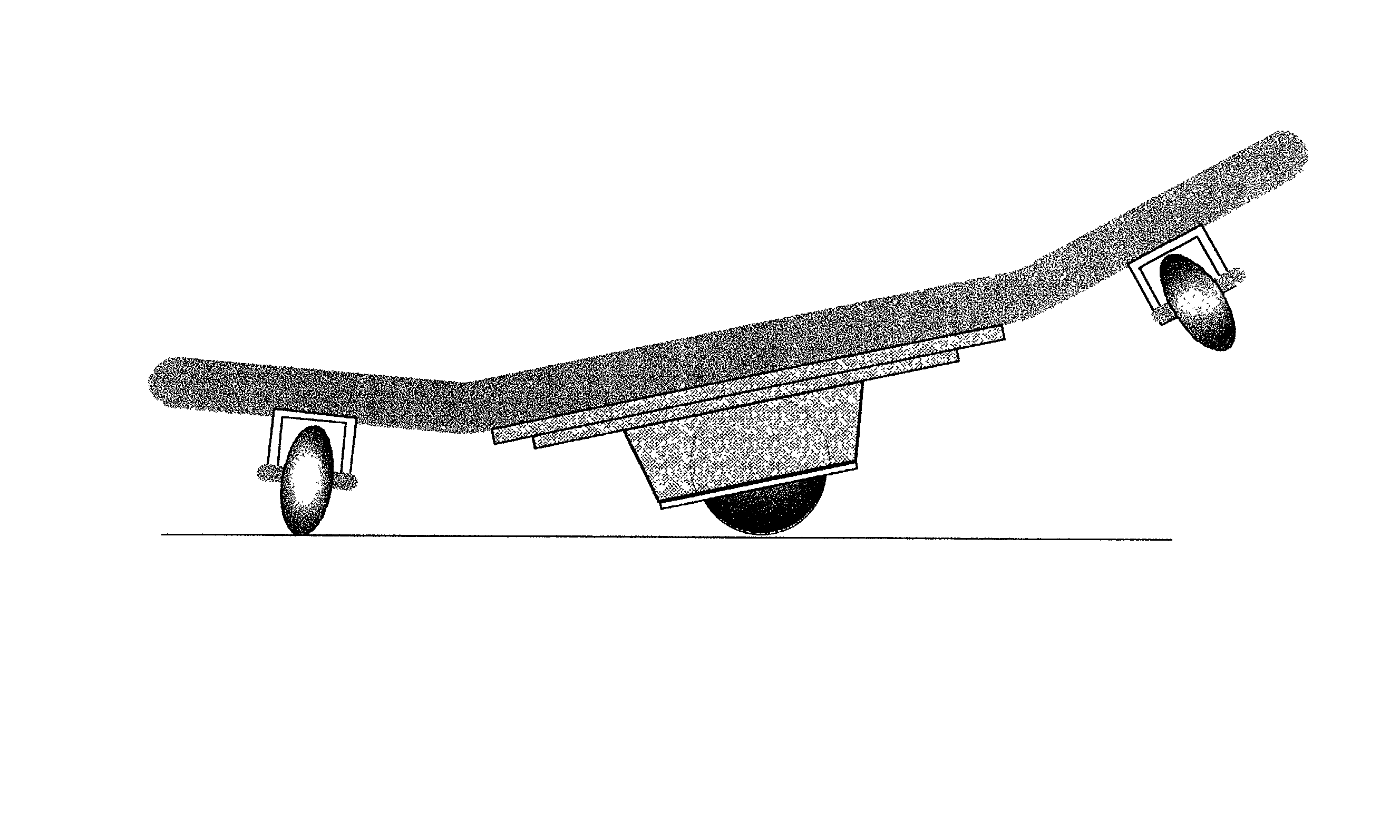

OMNIDIRECTIONAL SKATEBOARD

[0081] Another particularly preferred and more specialized embodiment of this invention is an omnidirectional skateboard shown in FIG. 5. This board comprises an integral, elongated, structurally rigid, single-piece, formed platform for supporting a skater. The platform has a central longitudinal axis along the length of the board, with a flat central portion 50 and bilateral, upwardly inclining wings 51 extending laterally from the center portion. Unlike a conventional skateboard, this invention does not require identification of fore and aft portions, as it is equally effective whatever end the user chooses to go forward. This allows a monumental increase in freedom of movement.

[0082] This skateboard has one or more longitudinally spaced spherical roller assemblies 60, as described hereinbefore, centrally attached to the underside of the flat central portion 50 of the platform structure. Each assembly housing 56 contains at least one spheric...

example three

C. EXAMPLE THREE

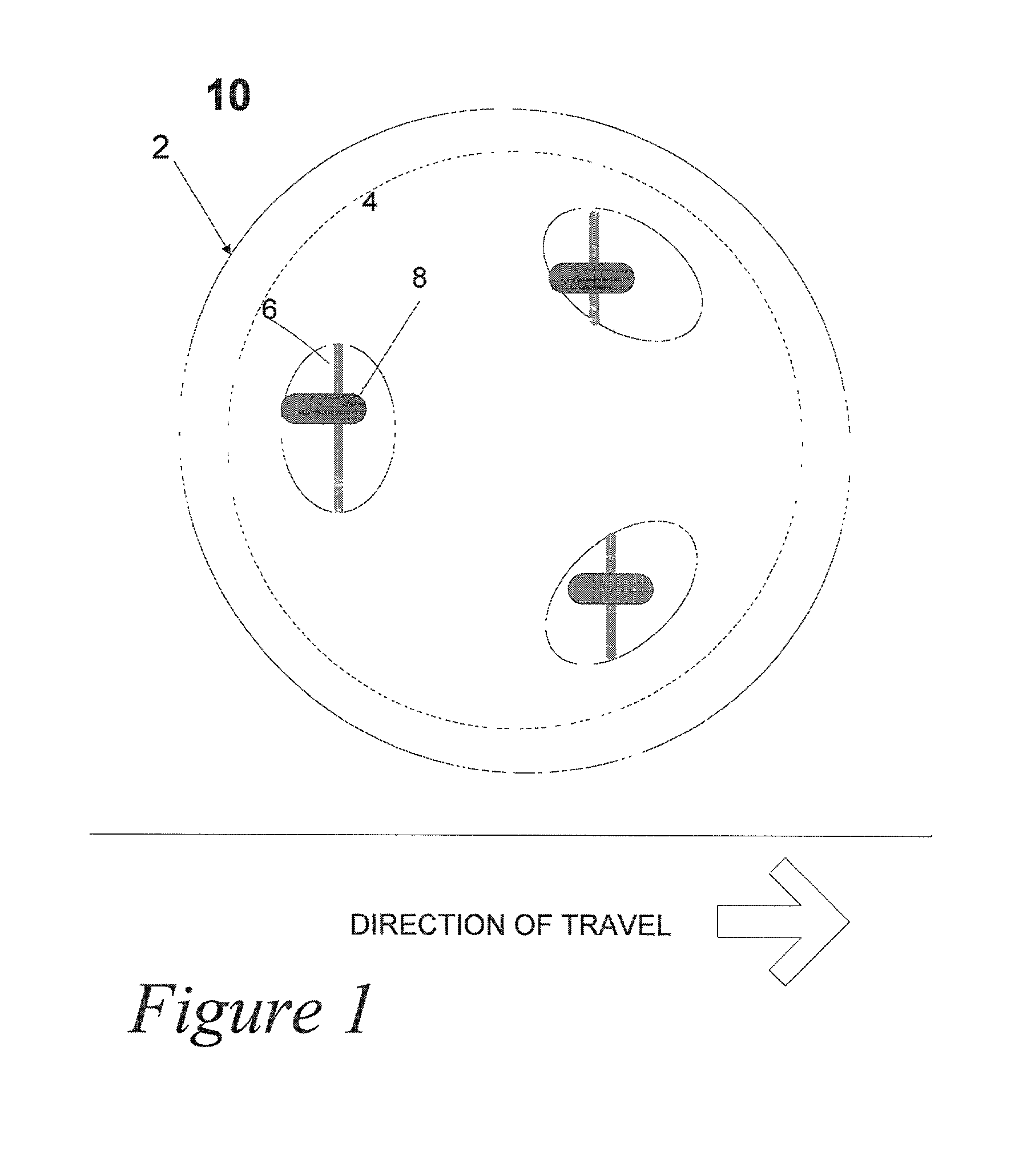

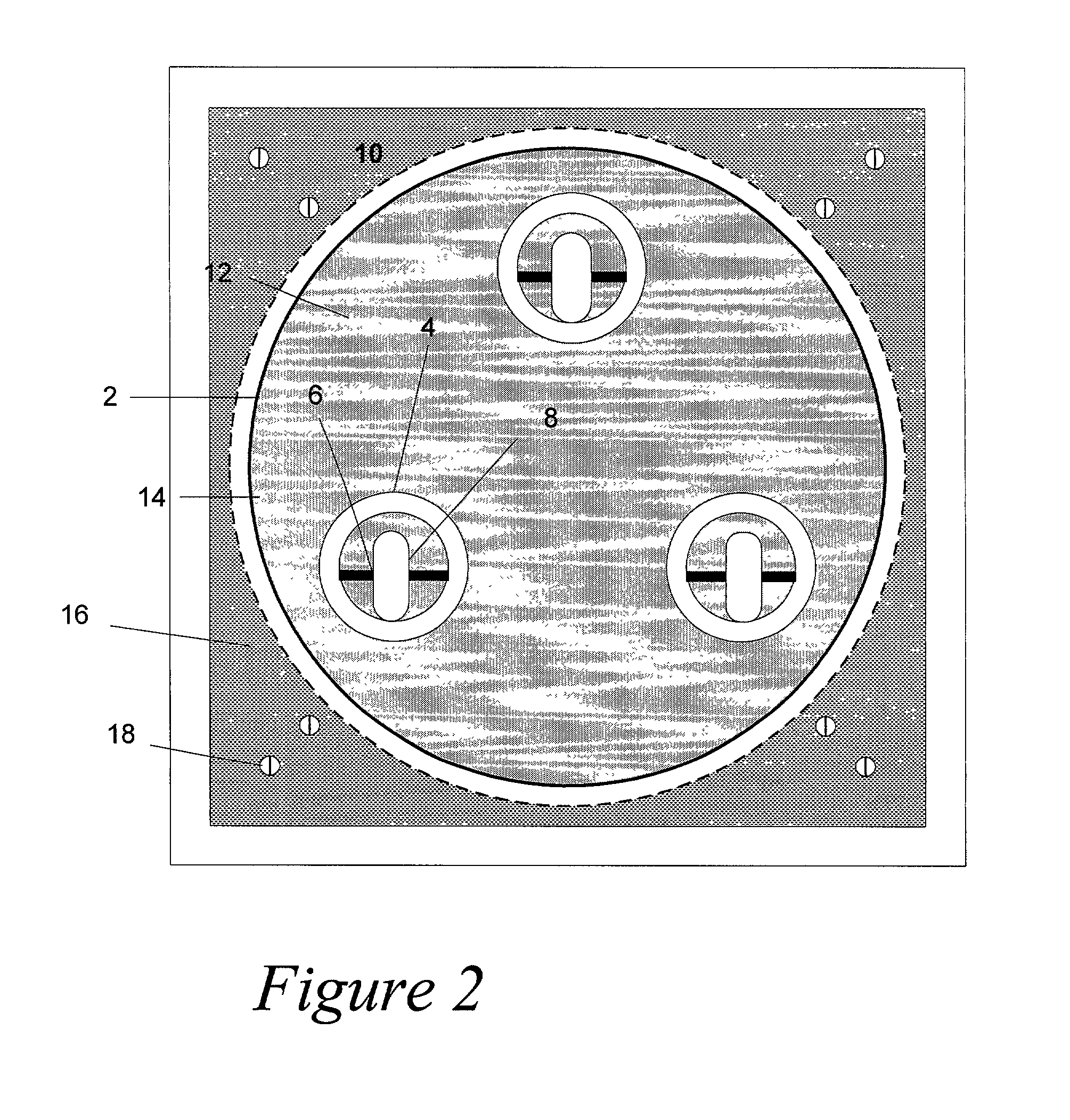

OMNIDIRECTIONAL PLATFORM

[0096] Another important and highly preferred embodiment of this invention is an omnidirectional platform, such as one appending a conveyor system. This platform may contain a plurality of attached housings as shown in FIG. 9, each having one or more concave spherical cavities. Attachment to a platform may be as illustrated in FIG. 2, 3, or screwed in as in FIG. 11. As described before, each cavity has an annular opening; however, in this case the opening is on the upper side of the housing (i.e., the housing is inverted), to form one or more spherical socket capable of containing a spherical roller 9. Such a platform can have as many spherical roller assemblies as is required, and in various configurations. A linear grid configuration is shown in FIG. 9.

[0097] As before, there is a plurality of cylindrical bores equidistantly geometrically disposed on the lower surface of the spherical socket, opposite the topside annular opening. There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com