Multi-plate frictional element

A friction element and component technology, applied in the field of multi-plate friction elements, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

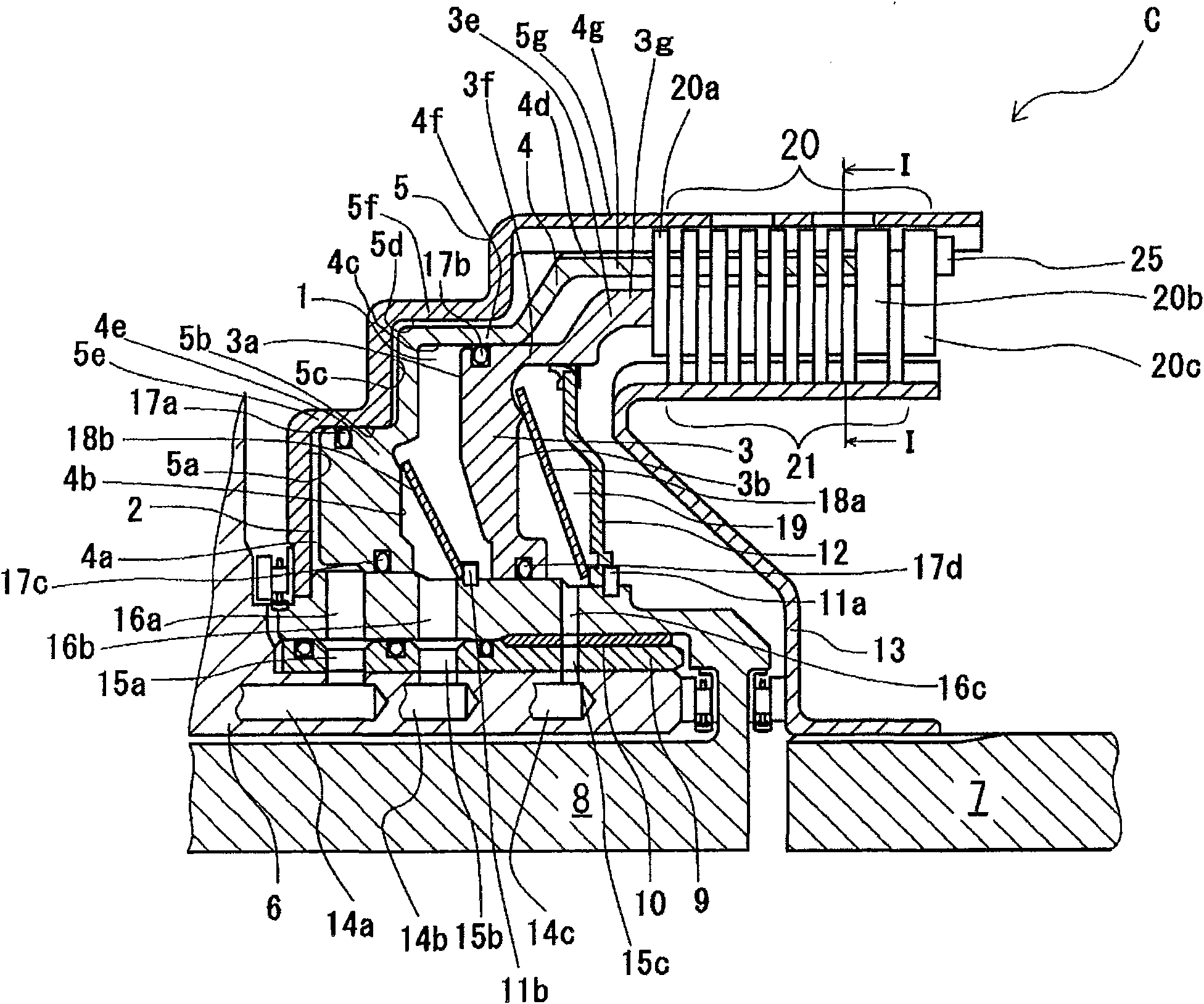

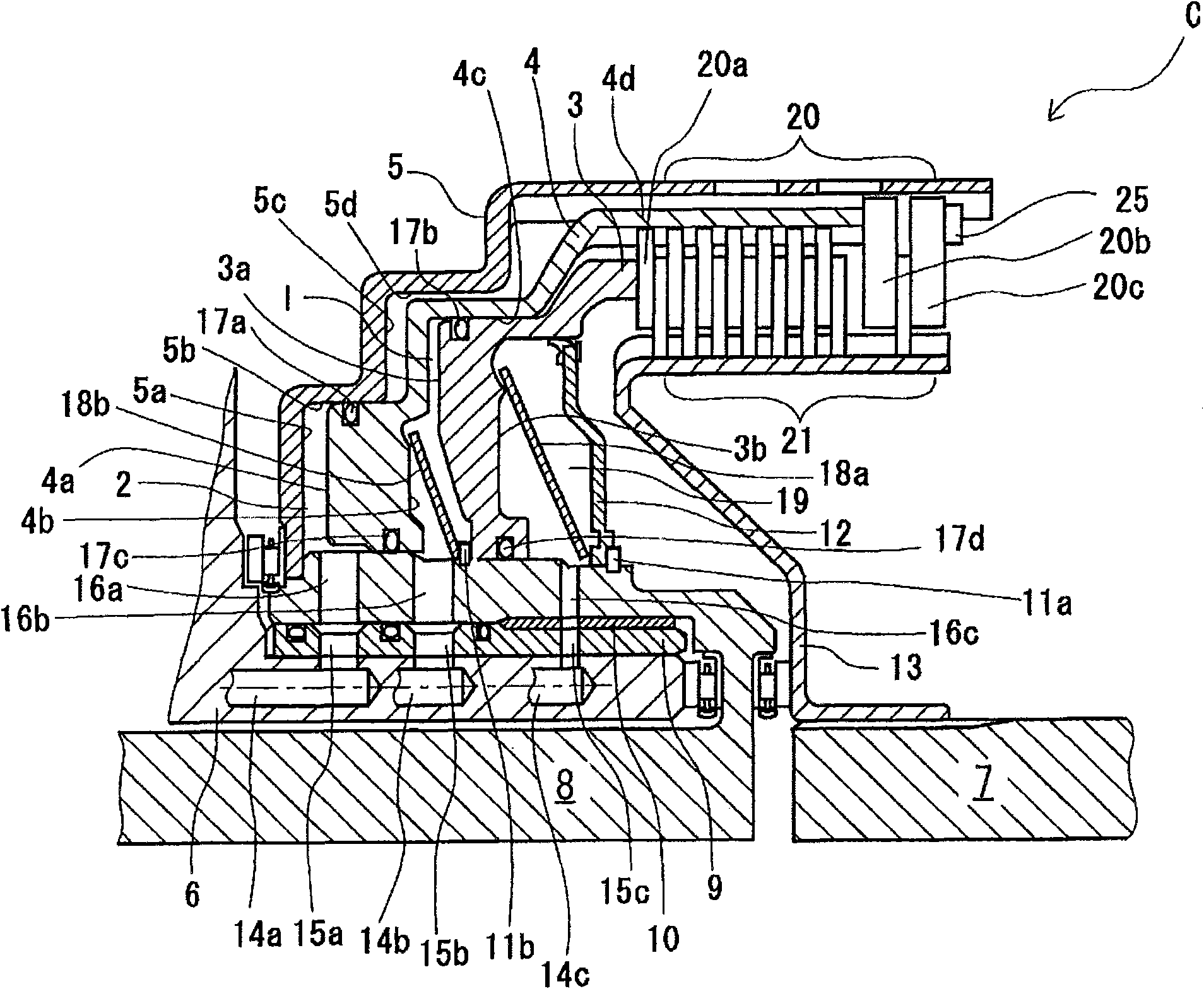

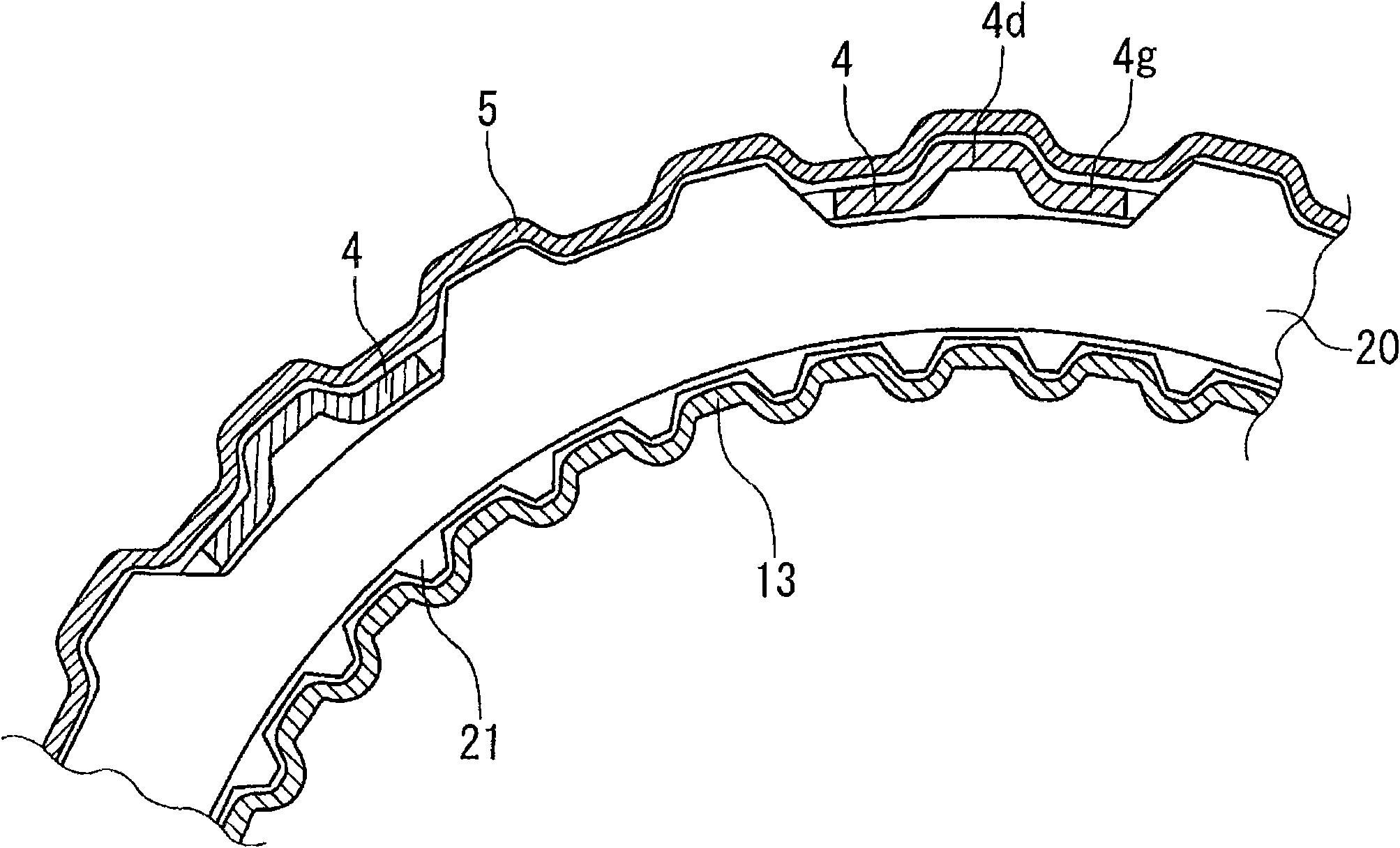

[0059] Embodiments of the present invention will be described below based on the drawings.

[0060] The clutch of the present embodiment is a so-called tandem piston type wet multi-plate clutch, and is engaged at shift stages having different engagement capacities such as the first speed and the fourth speed.

[0061] figure 1 , figure 2 is a sectional view of a clutch as a friction element of the first embodiment, figure 1 Indicates the connection state when the connection capacity is large, figure 2 Indicates the join status when the join capacity is low.

[0062] Also, in the following description, the figure 1 Use the left side as the front and the right side as the rear.

[0063] The clutch C is engaged to transmit power from the input rotary shaft 8 connected to the drive source side to the output shaft 7 connected to the wheel side.

[0064] Both the first piston 3 and the second piston 4 are accommodated in the clutch drum 5 so that the radially inner side ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com