Device for producing moulded pieces from fibrous material

A fiber material and molding technology, which is applied in the field of devices for manufacturing moldings from fiber materials, can solve the problems of difficulty in uniform filling of molds, restrictions on the mobility of blowing pipes, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

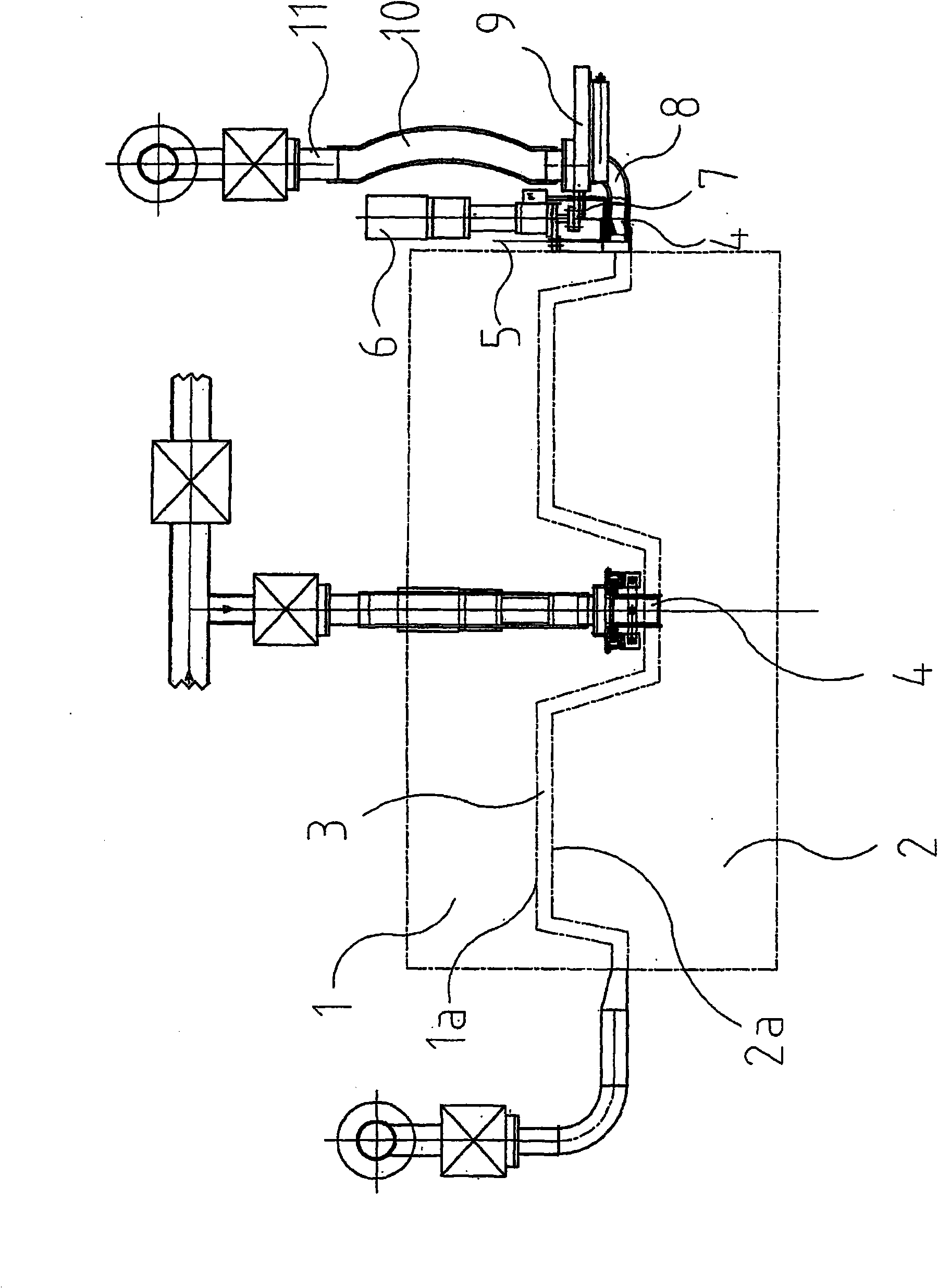

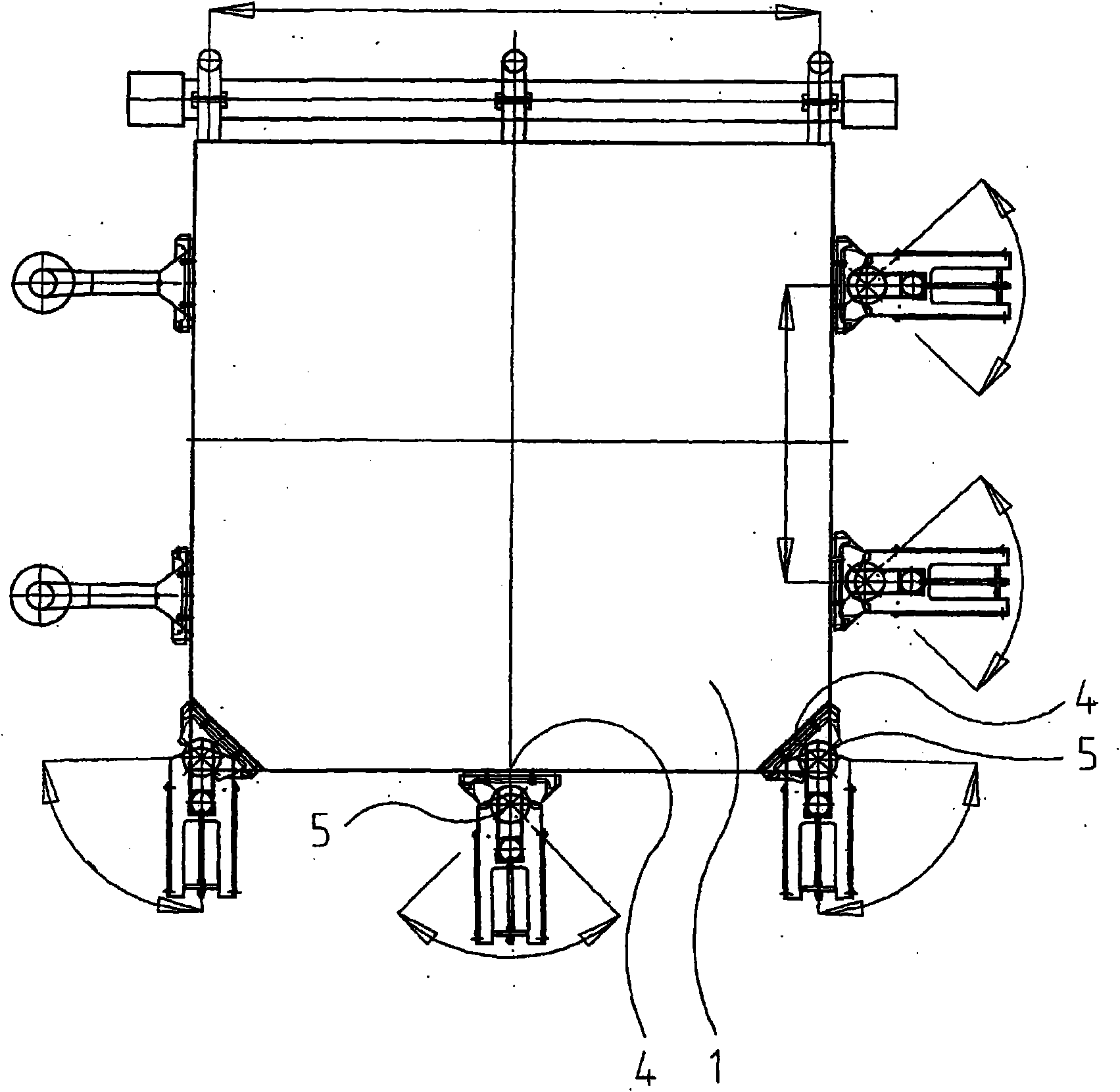

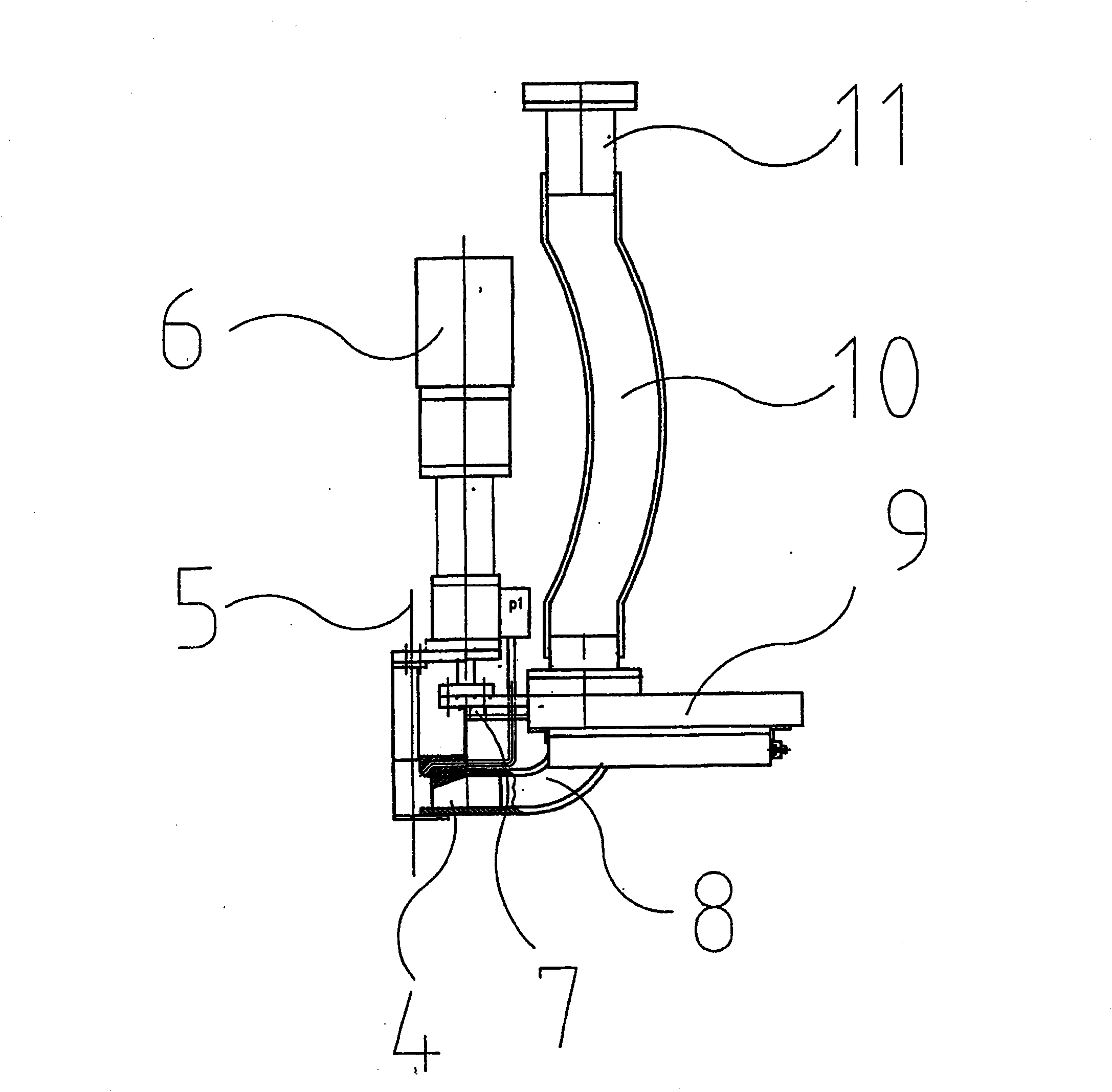

[0034] exist figure 1 In FIG. 2 , a mold can be seen comprising an upper mold 1 and a lower mold 2 assembled such that their inner sides 1 a and 2 a towards each other form a closed intermediate chamber 3 . Said intermediate chamber already defines the contour of the three-dimensional shaped part to be produced; however, it is advantageous that the upper mold 1 and the lower mold 2 are first used to produce a parison, which is then compacted by another upper mold into The final molded part. The insides 1a and 2a of the moulds are generally perforated in a screen-like manner so that the air flow loaded / carrying the synthetic fibres, which flows laterally into the intermediate chamber 3, can escape from the intermediate chamber 3, while the fibers accumulate in the center in the room. In this case, the air permeability of the inner walls 1 a and 2 a can be locally different in order to be able to vary the fiber filling, ie the fiber density, in the intermediate chamber 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com