Hinge and door device

一种门装置、铰链的技术,应用在铰链和门装置领域,能够解决费工夫等问题,达到紧凑收纳、防止追加部件、规模小型化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

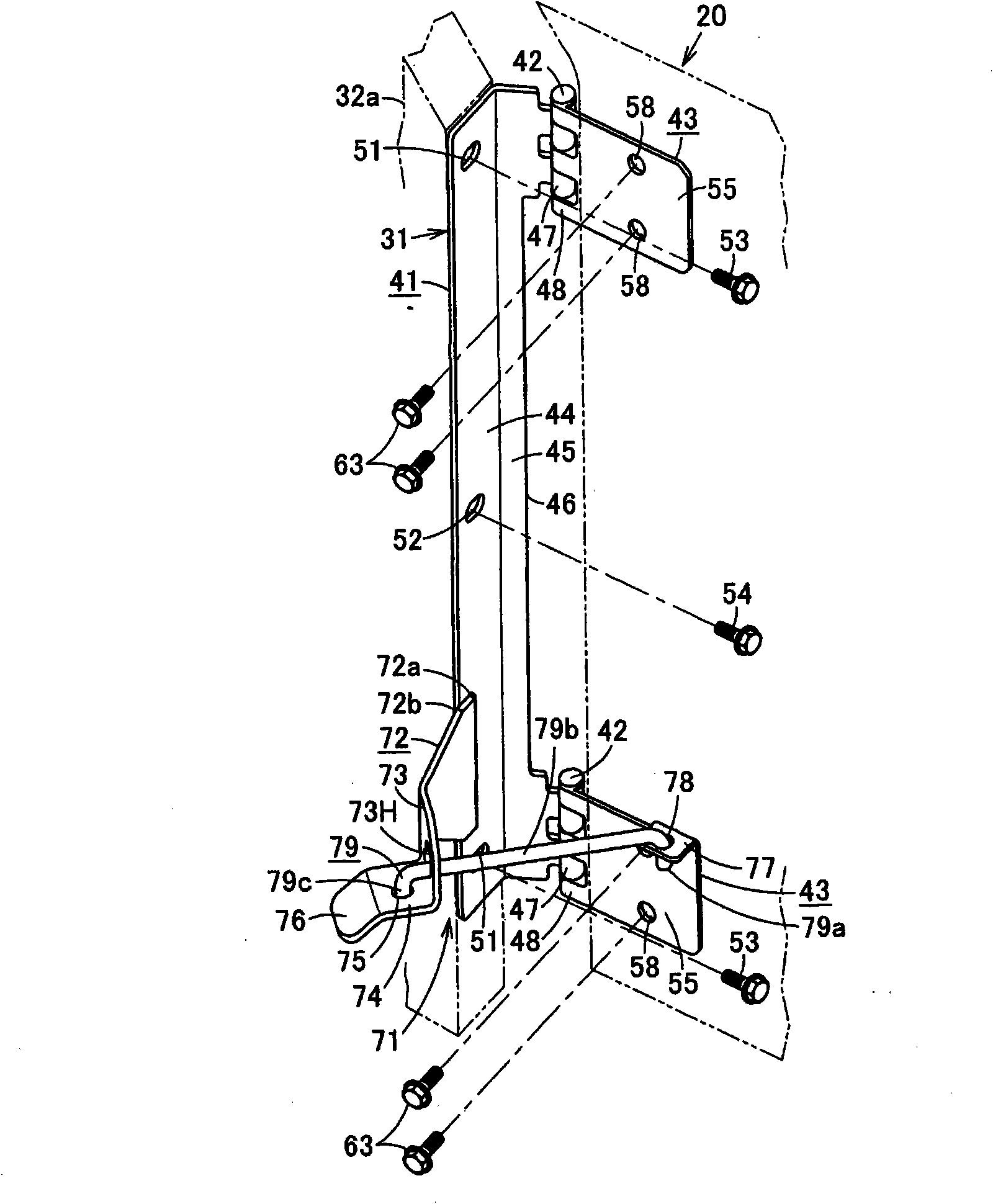

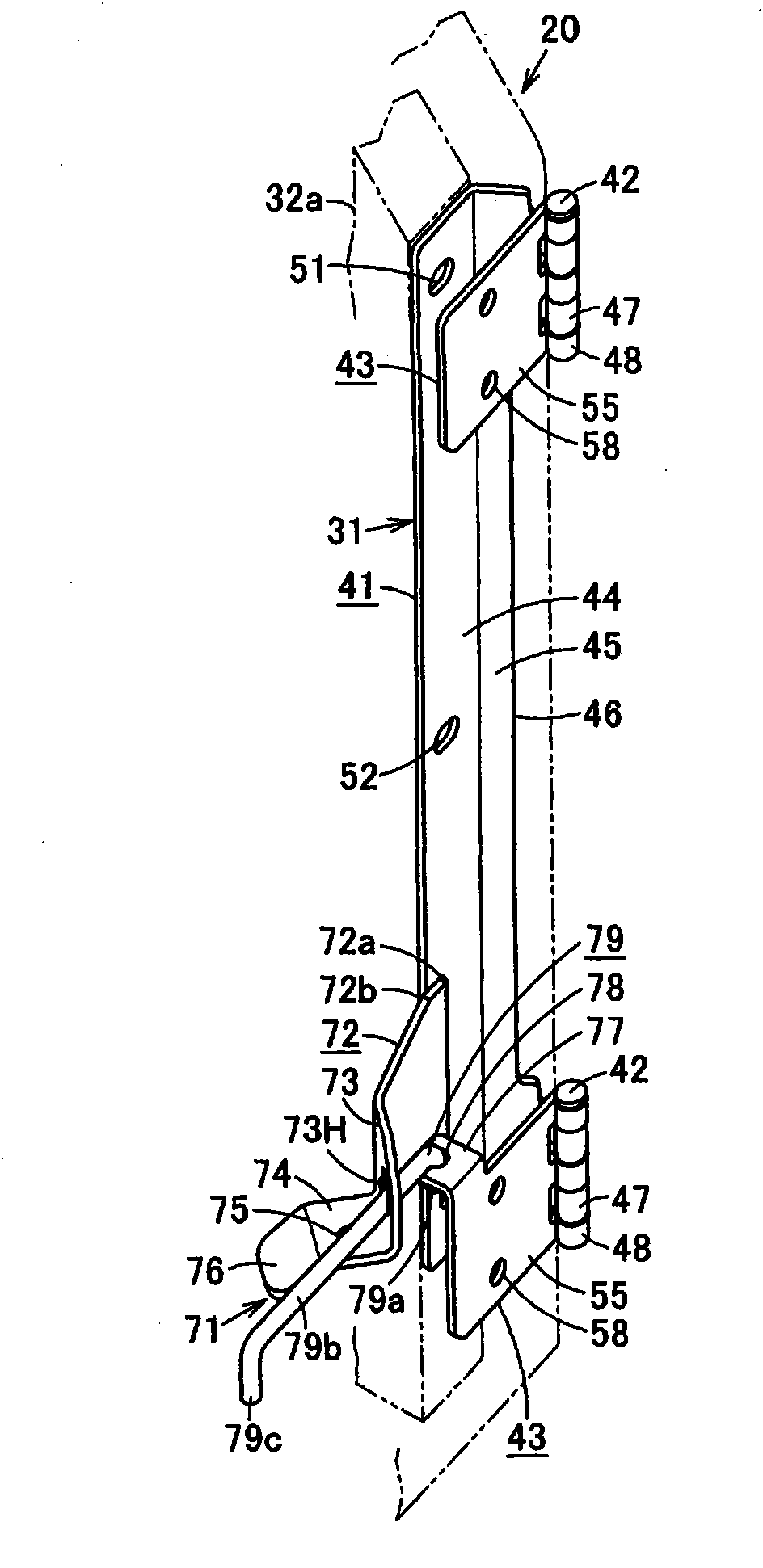

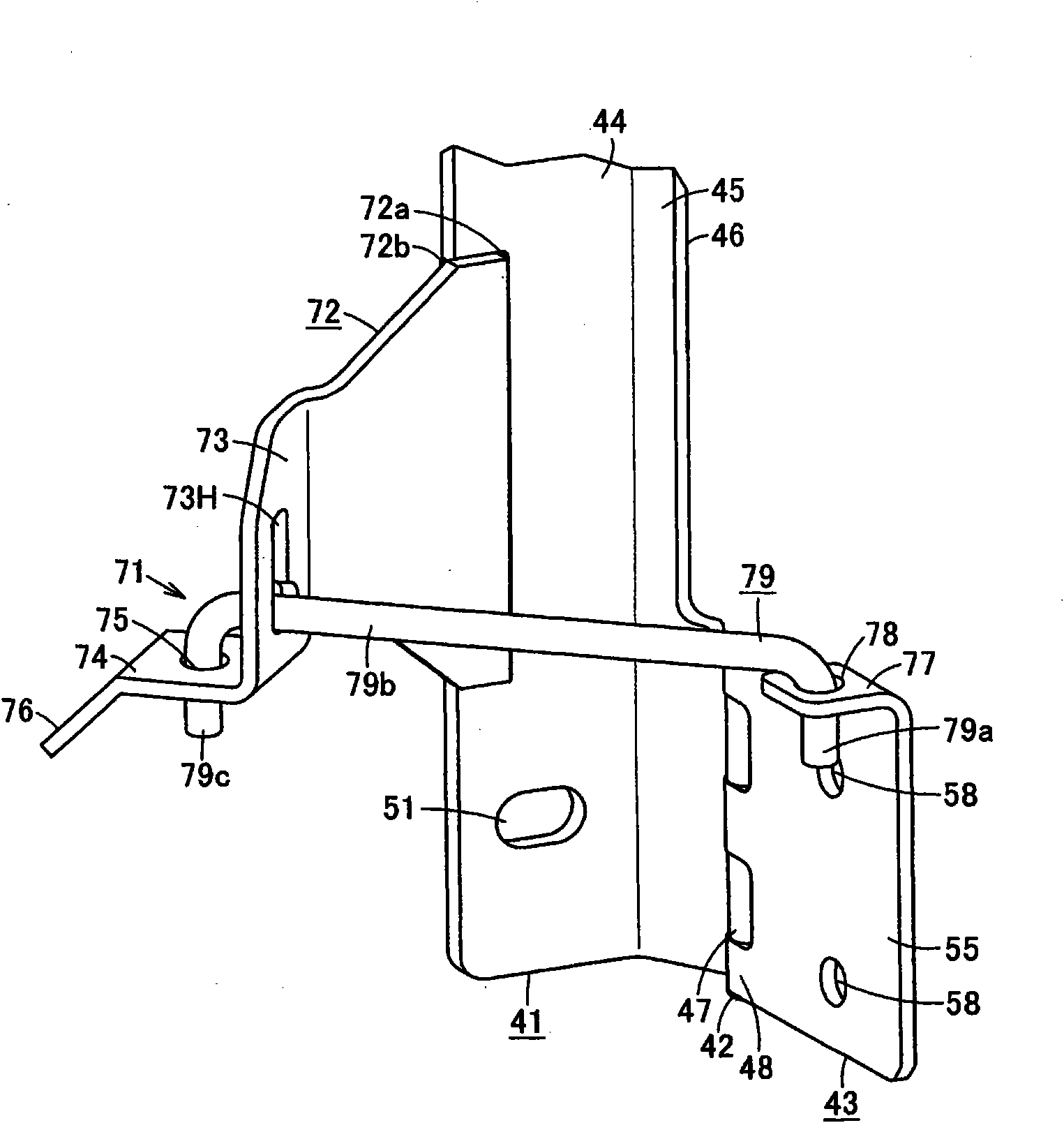

[0067] Below, refer to Figure 1 to Figure 11 The first embodiment shown, Figure 12 to Figure 16 The second embodiment shown, Figure 17 The third embodiment shown, Figure 18 to Figure 28 The fourth embodiment shown, Figure 29 The fifth embodiment shown and Figure 30 The sixth embodiment shown will describe the present invention in detail.

[0068] first of all, yes Figure 1 to Figure 11 The first embodiment shown will be described.

[0069] Figure 7 Shown is a hydraulic excavator 10 as an operating machine, and an upper revolving body 12 is rotatably provided on a lower traveling body 11 , and a driver's cab 13 , a working device 14 , and a power unit 15 such as an engine are attached to the upper revolving body 12 . The power unit 15 is covered by an upper cover 16, a side door 17, and the like.

[0070] Such as Figure 8As shown, one side of the door panel main body 20 of the side door 17 is installed on the frame 32 on the side of the machine body through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com