Harvester Stalk Cutting Device

A cutting device and harvester technology, applied in the direction of harvesters, cutters, crop processors, etc., can solve the problems of unfavorable soil absorbing its nutrients, nutrients easily absorbed by soil, and stems easily rotted by soil, etc., and achieve high efficiency , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

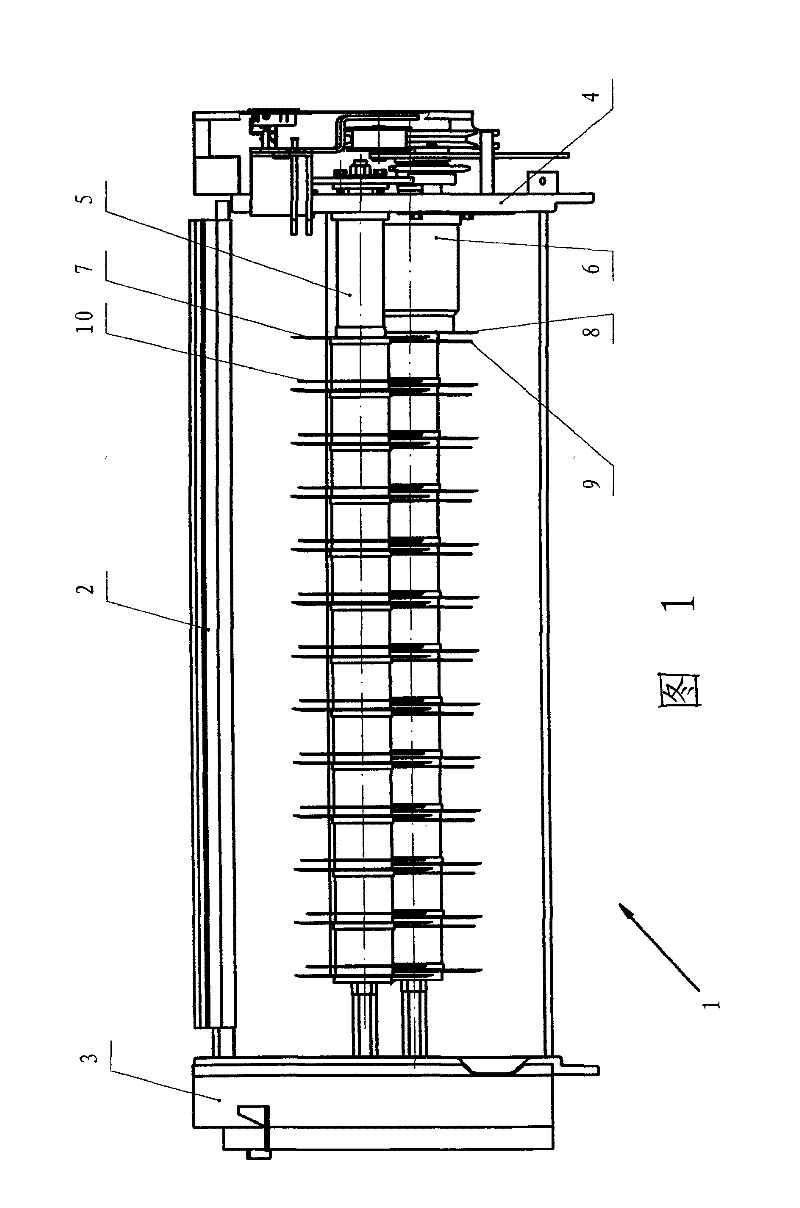

[0037] see figure 1 , The stalk cutting device 1 is made up of flip cover assembly 2, left side plate welding 3, right side plate welding 4, conveying knife shaft assembly 5, and grass cutting shaft assembly 6.

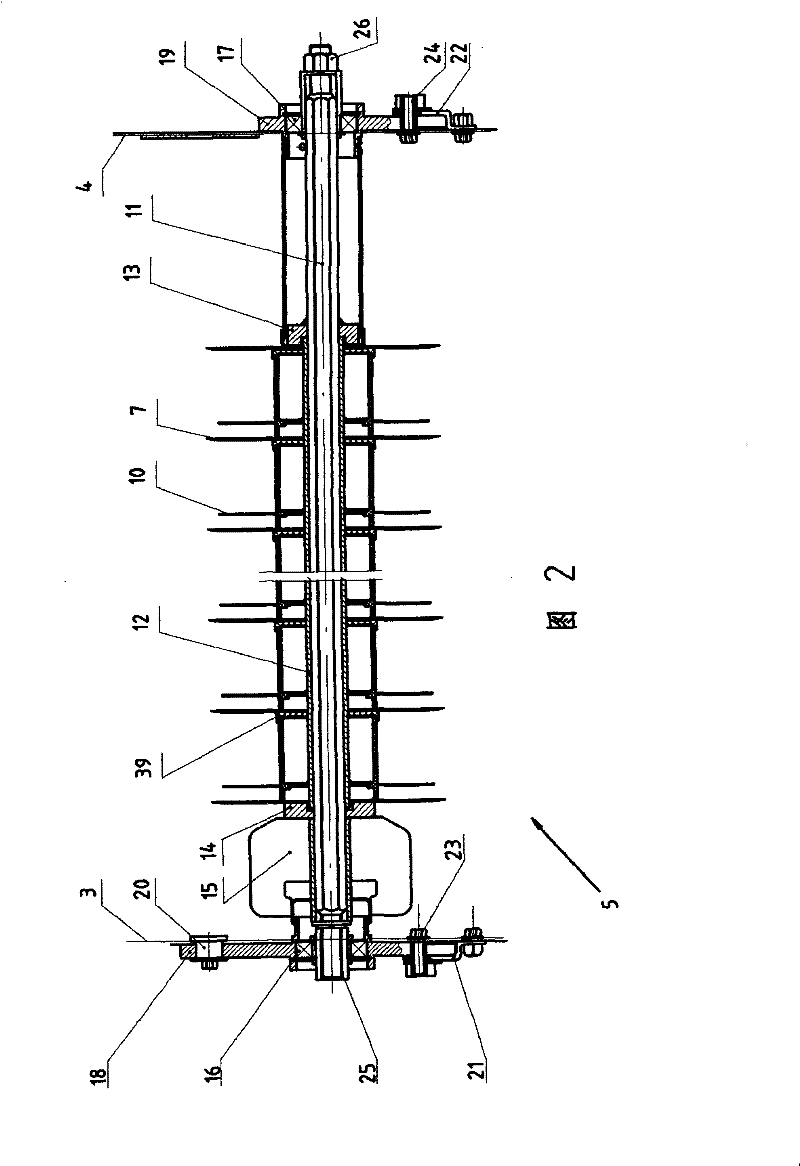

[0038] see figure 2 , the left and right ends of the conveying cutter shaft 11 of the conveying cutter shaft assembly 5 are respectively installed in the left bearing 16 and the right bearing 17, and the left bearing 16 and the right bearing 17 are respectively installed in the left bearing seat 18 and the right bearing seat 19, and the left bearing seat 18 And the right bearing seat 19 is respectively installed and fixed on the left side plate welding 3 and the right side welding 4 through the left pressing plate 21 and the right pressing plate 22, and the left bearing seat bolt 20 and the left pressing plate are respectively worn on the upper and lower parts of the left bearing seat 18 Bolt 23 makes the left bearing seat 18 be installed on the left side plate weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com