Punch press transmission equipment

A technology of transmission equipment and punching machines, applied in the direction of punching machines, presses, manufacturing tools, etc., can solve problems such as mold gaps, unqualified products, and products that cannot meet the standard quality requirements, and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

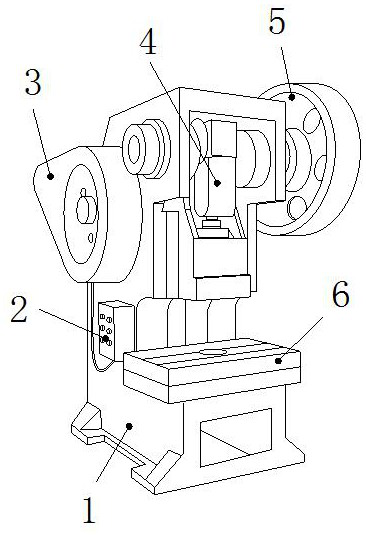

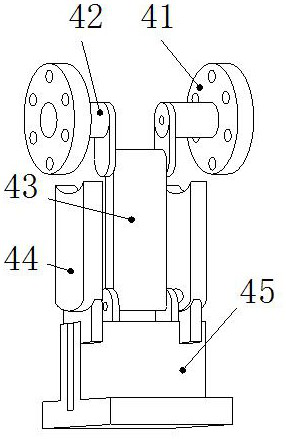

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The present invention provides a transmission device for a punching machine, the structure of which includes a base 1, a controller 2, a lower shaft wheel 3, a transmission stamping head 4, an upper shaft wheel 5, and a stamping table 6, and bolts on the outer side of the middle part of the base 1 and the inner side of the controller 2 connection, the inner side of the lower shaft wheel 3 is axially connected with the base 1, the transmission stamping head 4 is movable and engaged with the upper end of the base 1, the upper shaft wheel 5 is axially connected with the right side of the upper end of the transmission stamping head 4, and the stamping The platform 6 is installed on the upper end of the base 1, and the transmission stamping head 4 includes a runner 41, a crankshaft 42, a connecting rod 43, a degreaser 44, and a punch 45. The crankshaft 42 is embedded and connected to the inside of the runner 41, one ...

Embodiment 2

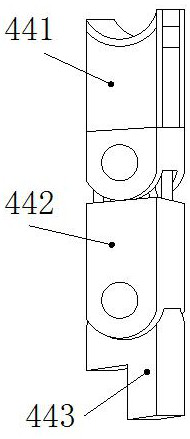

[0031] as attached Figure 5 to attach Figure 7 Shown:

[0032] Wherein, the bonding head 41e includes a bonding sheet e1, an oil suction pipe e2, a curved rod e3, a push rod e4, a sealing plate e5, a sealing cavity e6, and a wrapping strip e7, and the middle part of the lower end of the bonding sheet e1 is connected to the push rod e4 The upper end shaft is connected, the oil suction pipe e2 is connected between the bonding piece e1 and the oil suction pipe e2, the curved rod e3 is connected between the bonding piece e1 and the wrapping strip e7, and the outer side of the push rod e4 is connected to the sealing cavity e6 The inner surfaces are attached together, the upper side of the sealing plate e5 is welded to the lower side of the push rod e4, the upper end of the sealing chamber e6 is screwed to the oil suction pipe e2, the wrapping strip e7 is connected to the inner shaft of the outer cover 41d, and the oil suction The pipe e2 is made of rubber, which has the charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com