Method for shortening natural ageing time of tobaccos through increasing moisture of redried strips

A technology of aging time and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of not being able to adjust the moisture content of rebaked tobacco sheets, shorten the natural aging time, shorten the natural aging time of tobacco leaves, etc., and achieve natural aging The effect of shortening the curing time, improving the quality of sensory evaluation and reducing the storage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

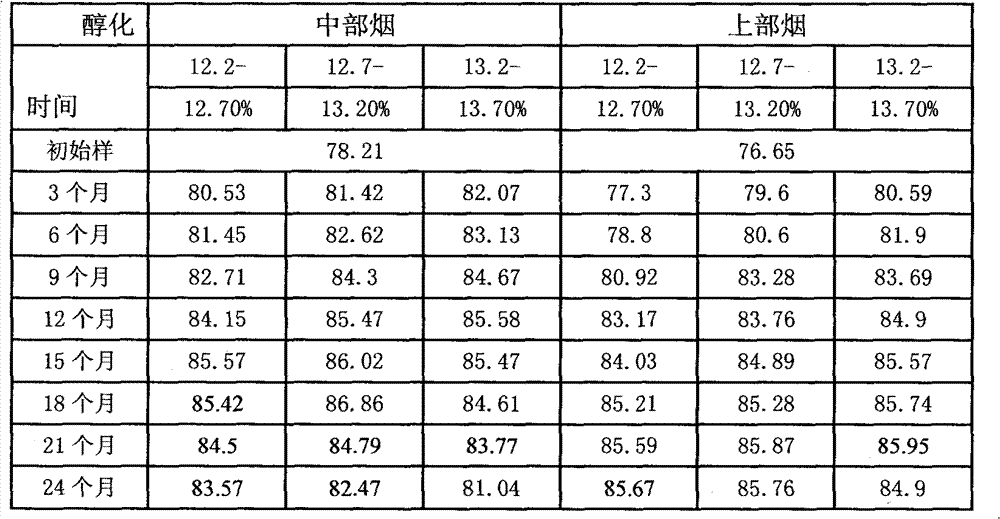

[0020] The present invention is implemented in Yuxi Hongta Group. details as follows:

[0021] 1. Setting of smoke moisture in rebaked slices

[0022] 1.1 The moisture content of the recured slices of the middle tobacco and the upper tobacco is set at 12.2-12.7%, 12.7%-13.2%, and 13.2%-13.7%;

[0023] 1.2 Sampling method

[0024] For each treatment of the re-cured tobacco leaves in the test, 1Kg was sampled case by case or board during the process of threshing and re-baking. Then, after mixing the samples from each case evenly, 5Kg was retained as the original sample (filled with nitrogen and stored at low temperature) every 3 months. One sample.

[0025] Using the plum-blossom-shaped punching sampling method, three boxes are randomly sampled each time in the same treatment, and after mixing evenly, they will be used as this analysis sample (the sample size is not less than 2Kg). In order to prevent the impact on the air permeability of the cigarette pack after punching, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com